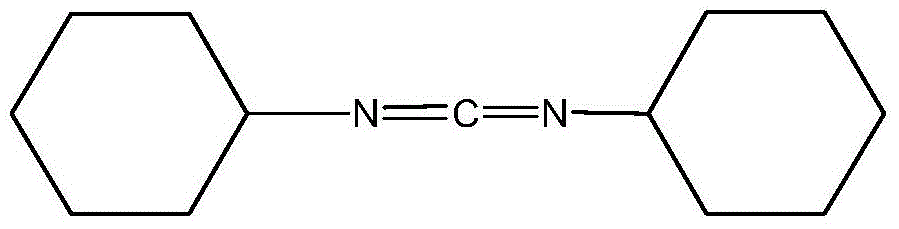

A kind of production method of recycling waste water to prepare n,n'-dicyclohexylcarbodiimide

A technology of dicyclohexylcarbodiimide and a production method, which is applied in the field of organic compound synthesis, can solve the problems of high cost, increased cost, unfavorable operating environment, etc., and achieves the effects of reducing emissions and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

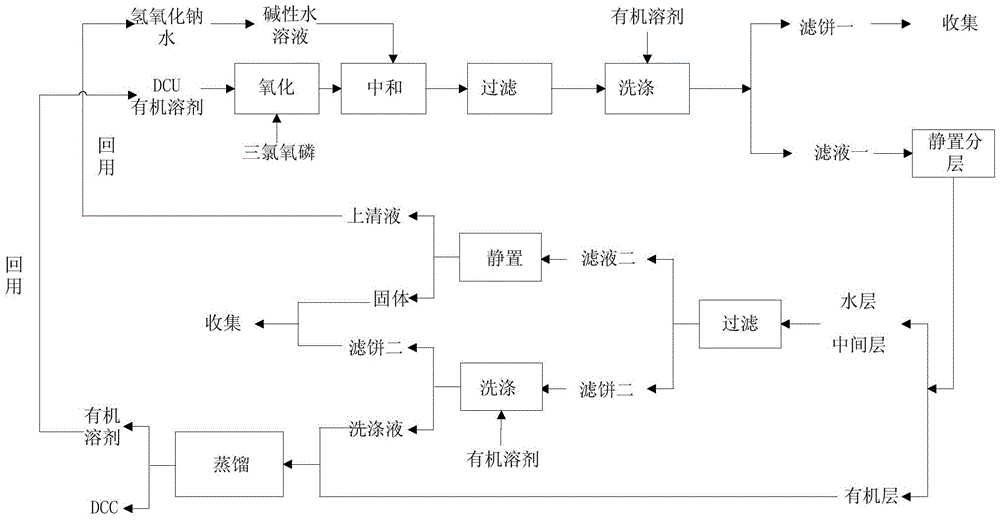

Method used

Image

Examples

Embodiment 1

[0039] Put 5kg of N,N'-dicyclohexyl urea raw material into 10kg of water, stir and soak for 40min, centrifuge the soaked DCU for dehydration, and then dry it in an oven at 110--120℃ until the water content is lower than 0.5%.

[0040] 175 g of chloroform was added into the three-necked flask, and 40.0 g of dried DCU was added under stirring. Weigh 30g of phosphorus oxychloride and add it to a 250mL dropping funnel. Phosphorus oxychloride was added dropwise to the three-necked flask under stirring, and the addition was completed within 30 minutes. After the addition was complete, the reaction was maintained at 55-60°C for 2 hours. Pour the reaction solution into the dropping funnel.

[0041] Add 400 g of waste water to the three-necked flask, add 45 g of solid sodium hydroxide under stirring, and stir for 20 minutes until all the sodium hydroxide is dissolved. Then the reaction solution was added dropwise to the three-neck flask, and the addition was completed in 60 minutes....

Embodiment 2

[0045] Referring to Example 1, the difference is that dichloromethane is used instead of chloroform. The reaction temperature after the dropwise addition of phosphorus oxychloride is 40-42°C; the neutralization reaction temperature is controlled below 40°C. The yield of DCC was 81.5%, and the purity was 99.4%.

[0046] It can be seen that in the present invention, the waste water containing inorganic salt produced by the reaction is separated from the system by filtration and then reused as a raw material, which reduces the discharge of waste water and the impact on the environment. At the same time, the use of the waste water containing saturated phosphate and sodium chloride of the present invention has no obvious influence on the product yield and purity of the DCC process prepared by DCU.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com