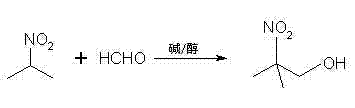

Method for preparing 2-nitro-2-methyl-1-propanol

A technology of nitropropane and methyl, which is applied in the field of preparation of 2-nitro-2-methyl-1-propanol, can solve the problems of complicated operation, low yield and high energy consumption, and achieve simple process and high product quality. High yield and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Dissolve 1g of potassium hydroxide in 25ml of methanol to form a solution, then add 30g (1mol) of paraformaldehyde into the solution, stir until dissolved, and form a solution for later use.

[0024] Then add 89g (1mol) 2-nitropropane into a 500ml flask, slowly drop the solution into the flask while stirring, and the dropping time is 30min. Then stirred and reacted at 35° C. for 1 h; after the reaction was completed, concentrated sulfuric acid was added dropwise to neutralize to a pH value of 4.5, and filtered.

[0025] The filtrate was distilled under reduced pressure to remove low-boiling impurities such as methanol and unreacted 2-nitropropane to obtain 113.4 g of 2-nitro-2-methyl-1-propanol crystals. The gas chromatogram of this crystal was consistent with that of 2- The standard spectrogram of nitro-2-methyl-1-propanol is consistent, and its yield is 95.3% after detection.

Embodiment 2

[0027] Dissolve 1g of triethylamine in 25ml of methanol to form a solution, then add 30g (1mol) of paraformaldehyde into the solution, stir until dissolved and form a solution for later use.

[0028] Then add 89g (1mol) 2-nitropropane into a 500ml flask, slowly drop the solution into the flask while stirring, and the dropping time is 30min. Then stirred and reacted at 45°C for 1.5h; after the reaction was completed, concentrated sulfuric acid was added dropwise to neutralize to a pH value of 3.5, and filtered.

[0029] The filtrate was distilled under reduced pressure to remove low-boiling impurities such as methanol and unreacted 2-nitropropane to obtain 111.7 g of 2-nitro-2-methyl-1-propanol crystals. The gas chromatogram of the crystals was consistent with that of 2- The standard spectrum of nitro-2-methyl-1-propanol is consistent, and its yield is 93.9% after detection.

Embodiment 3

[0031] First dissolve 1g of sodium hydroxide in 100ml of methanol to form a solution, then add 30g (1mol) of paraformaldehyde to the solution, stir until dissolved and form a solution for later use.

[0032] Then add 89g (1mol) 2-nitropropane into a 500ml flask, slowly drop the solution into the flask while stirring, and the dropping time is 1h. Then stirred and reacted at 20°C for 3h; after the reaction was completed, concentrated sulfuric acid was added dropwise to neutralize to a pH value of 4, and filtered.

[0033] The filtrate is subjected to vacuum distillation to remove low-boiling impurities such as methanol and unreacted 2-nitropropane, to obtain 115.0 g of 2-nitro-2-methyl-1-propanol crystals, and the gas chromatogram of the crystals is consistent with that of 2- The standard spectrogram of nitro-2-methyl-1-propanol is consistent, and its yield is 96.6% after detection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com