Preparation method of nano-silver/graphene derivative surface enhanced Raman substrate

A surface-enhanced, Raman matrix technology, applied in the field of molecular spectroscopic analysis and detection, can solve the problems of decreased sensitivity and accuracy, impact on performance, high energy consumption, etc., and achieve improved surface-enhanced Raman performance and strong surface-enhanced Raman performance , The effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Graphene derivative films help to adsorb sugar reducing agents and provide sites for the growth of nano silver particles. Therefore, graphene derivatives play a vital role; Example 1 refers to previous experience without graphene A silver mirror reaction is used to prepare a nano-silver film on the quartz substrate of the derivative film. The experimental steps are as follows:

[0044] 1) Pretreatment of the quartz substrate: The quartz substrate was ultrasonically cleaned in acetone, ethanol, and deionized water for 5 minutes, and then dried with nitrogen.

[0045] 2) The quartz substrate in step 1) is vertically immersed in a 10 mg / mL glucose aqueous solution for 20 minutes, then taken out, and dried with nitrogen.

[0046] 3) The configuration of silver ammonia solution: The configuration of silver ammonia solution: Under stirring conditions, add 2% aqueous ammonia solution dropwise to 0.4 mol / L concentration of silver salt aqueous solution until the precipitate is complet...

Embodiment 2

[0051] The difference between Example 2 and Example 1 is that the substrate is first coated with a graphene derivative film. Specific steps are as follows:

[0052] a) Preparation of graphene derivatives-graphene oxide film:

[0053] (1) Add graphene oxide powder to deionized water, add 0.1 mg graphene oxide per mL, and ultrasound for 2 h to obtain a graphene oxide colloidal solution.

[0054] (2) Add deionized water to PDDA with a mass fraction of 20%, and the volume ratio of deionized water to 20% PDDA is 4:1.

[0055] (3) Pretreatment of the quartz substrate: The quartz substrate was ultrasonically cleaned in acetone, ethanol, and deionized water for 5 minutes, and then dried with nitrogen.

[0056] (4) The pretreated quartz substrate was immersed in the graphene oxide solution for 20 minutes, then rinsed with deionized water, dried with nitrogen, immersed in the PDDA sol for 20 minutes, and rinsed with deionized water. Repeat this step once.

[0057] b) Put the graphene oxide film o...

Embodiment 3

[0064] The difference from embodiment 2 is that step a) in step (4) of embodiment 3 repeats this step twice.

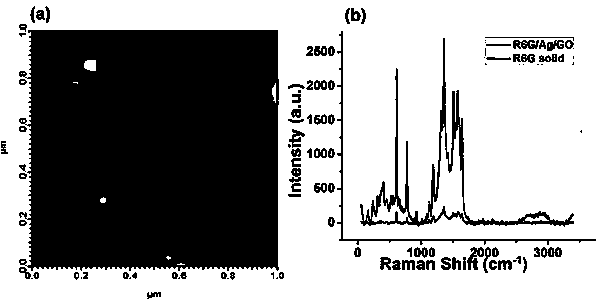

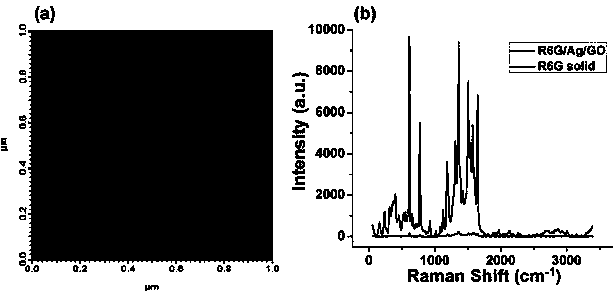

[0065] image 3 (A) is the AFM image of the composite film. It can be clearly seen from the figure that the nano-silver particles uniformly cover the entire surface of the quartz substrate, and the size of the nano-particles has increased to 75 nm.

[0066] image 3 (B) It is the surface enhanced Raman diagram of crystal violet molecules of the composite film. It can be seen from the figure that the performance of the film has been greatly improved, and the surface Raman enhancement factor has been increased to 1.2*10 8 .

[0067] Example 3 once again proves that the graphene oxide film affects the growth of nano silver particles; comparing Examples 1 and 2, the performance of the composite film of Example 3 is greatly improved. This is not only because the size and number of nano-silver particles have increased, and the distance between the particles has decreased, but also...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com