Salinomycin-loaded micelle as well as preparation method and application thereof

A technology of loading salinomycin and salinomycin sodium, which is applied in the field of medicine, can solve the problems of systemic toxicity, no liver cancer treatment, no obvious disease relief or life extension effect, and achieve the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

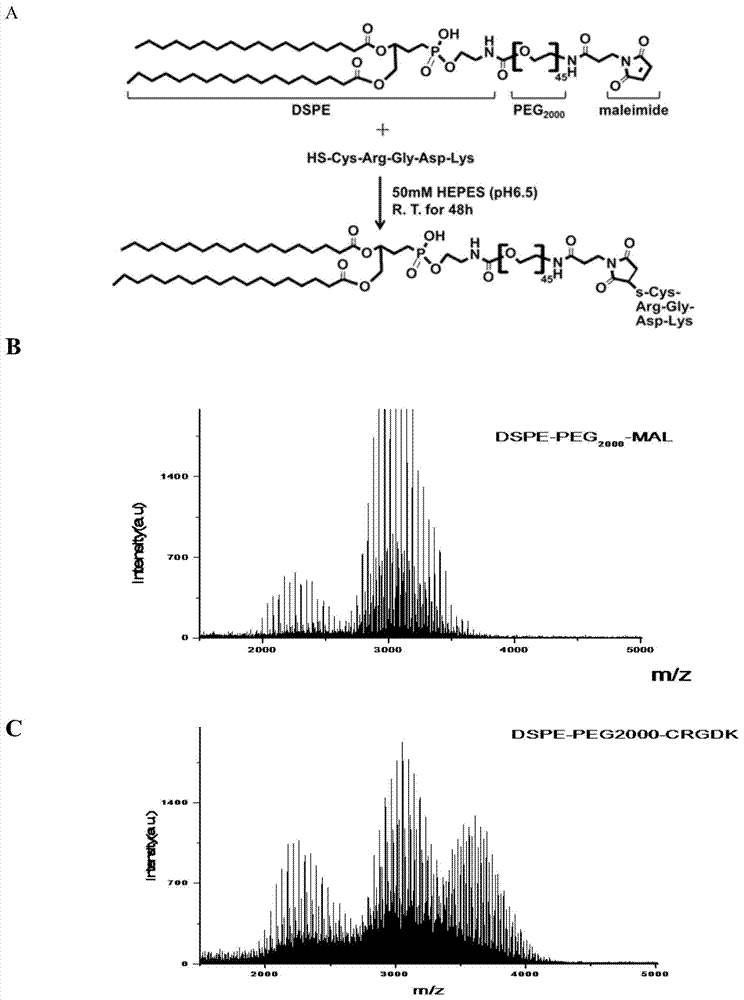

[0070] Embodiment 1: the synthesis of the block copolymer of DSPE-PEG2000-CRGDK

[0071] Such as figure 1 As shown in A, accurately weigh 0.3mg CRGDK and 1.5mg DSPE-PEG2000-MAL and dissolve them in 2ml 50mM HEPES buffer solution (pH 6.5), and magnetically stir at room temperature for 48h. - Maleimide group binding in PEG2000-MAL. After the reaction, the reaction solution was put into a dialysis bag (Spectra / Por, MWCO1000), and dialyzed in deionized water for 24 hours, wherein the dialysate was changed every 12 hours.

[0072] After dialysis, the solution in the bag was freeze-dried for use.

[0073] The result is as figure 1 As shown in B, the relative molecular weight of DSPE-PEG2000 is concentrated in 2800-3400, while figure 1 C DSPE-PEG2000-CRGDK has a peak at 3500-4000, and the increased molecular weight value is consistent with the molecular weight of CRGDK at 700. The results show that CRGDK is successfully connected to DSPE-PEG2000.

Embodiment 2

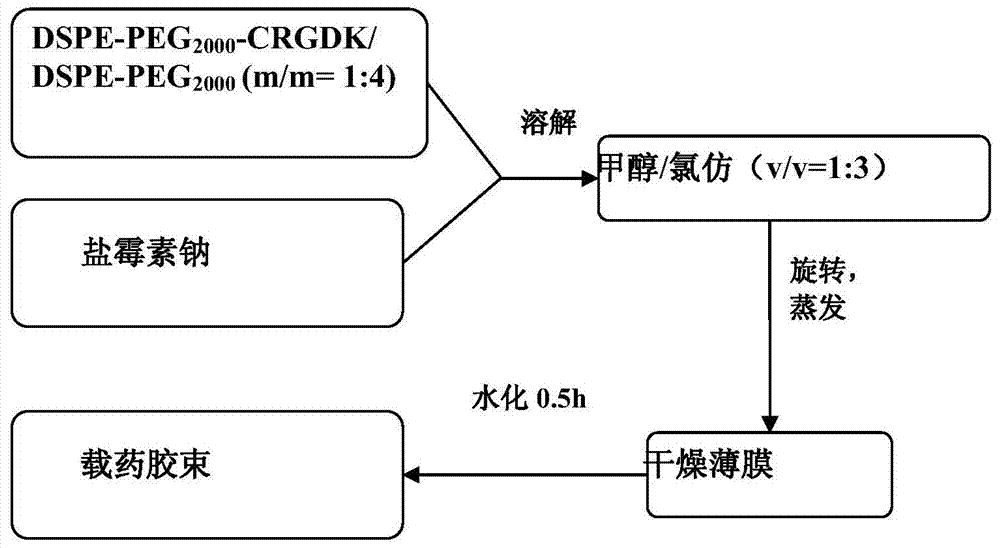

[0074] Embodiment 2: the preparation of salinomycin sodium micelle

[0075] Such as figure 2 As indicated, dissolve 1mg DSPE-PEG2000-CRGDK and 4mg DSPE-PEG2000 in 3ml chloroform, and dissolve another 0.5mg salinomycin sodium in 1ml methanol, mix the above two solutions, and evaporate under reduced pressure at 35°C for 4h The organic solvent is removed to form a dry film. Add 2 mL of pH 7.4 phosphate buffer to the bottle and fill it with nitrogen gas, and hydrate for 30 min. Unencapsulated salinomycin sodium was removed by passing through a 50 nm polycarbonate membrane.

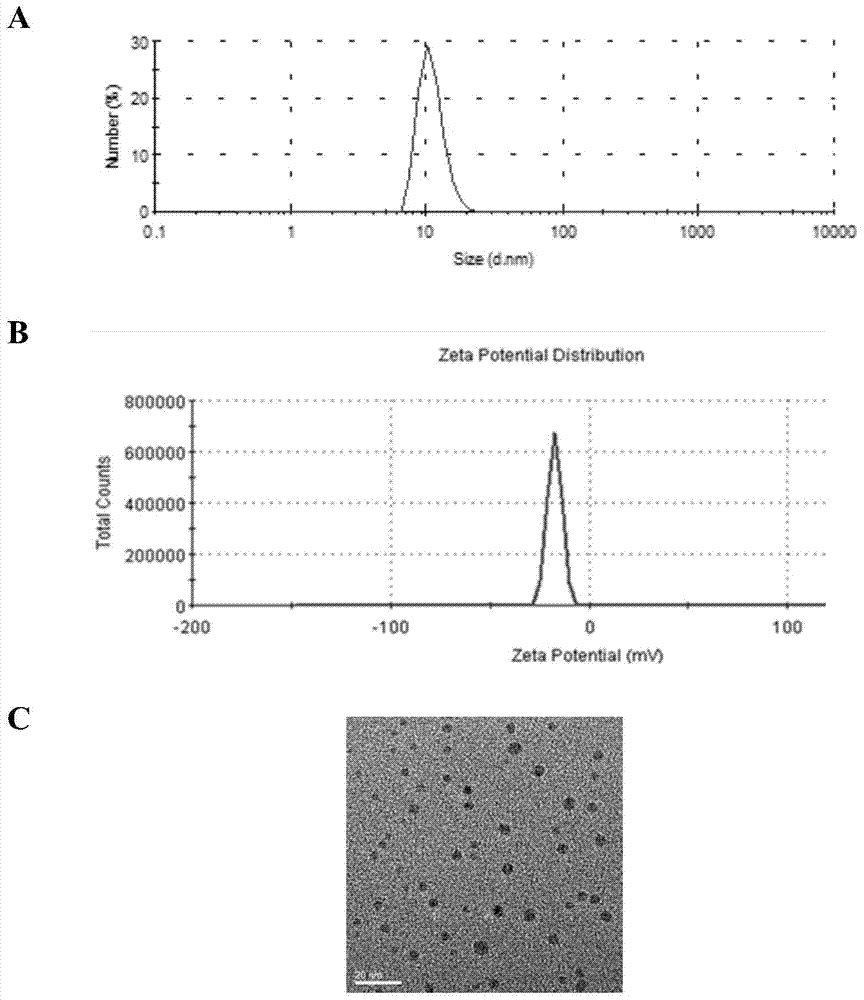

[0076] The size of the micelles prepared by thin film dispersion method is at 13nm ( image 3 A), the zeta potential is maintained at around -13mV ( image 3 B), transmission electron microscope ( image 3C) shows that the DSPE-PEG2000-CRGDK mixed micelles prepared by the present invention are spherical and have a typical core-shell structure. This experiment shows that the DSPE-PEG2000-CRGDK self-assem...

Embodiment 3

[0077] Embodiment 3: Optimization of the preparation process of salinomycin micelles

[0078] (1) Screening of carrier total amount and salinomycin sodium mass ratio

[0079] Dissolve (0.5, 1, 1.5) mg DSPE-PEG2000-CRGDK and (2,4,6) mg DSPE-PEG2000 in 3ml chloroform respectively, and dissolve another 0.5mg salinomycin in 1ml methanol, (i.e. the total amount of carrier The mass ratio to salinomycin sodium is 1:5, 1:10, and 1:15 respectively) Mix the above two solutions, and remove the organic solvent by rotary evaporation under reduced pressure at 35°C for 4 hours to form a dry film. Add 2 mL of pH 7.4 phosphate buffer to the bottle and fill it with nitrogen gas, and hydrate for 30 min. Unencapsulated salinomycin sodium was removed by passing through a 50 nm polycarbonate membrane. The results showed that when the mass ratio was 1:10, the encapsulation efficiency of micelles was the highest, see Table 1 for details.

[0080] Table 1: Effects of the ratio of the total mass of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com