An in situ large-area controlled synthesis of perovskite ch based on lead thin films 3 nh 3 pbi 3 Chemical Methods for Thin Film Materials

A chemical method and thin-film material technology, applied in metal material coating process, ion implantation plating, coating, etc., can solve problems such as difficult large-area preparation and continuous production, poor device repeatability, and impure products, etc., to achieve Extensive laboratory preparation and industrial application prospects, excellent crystallinity, and efficient reaction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

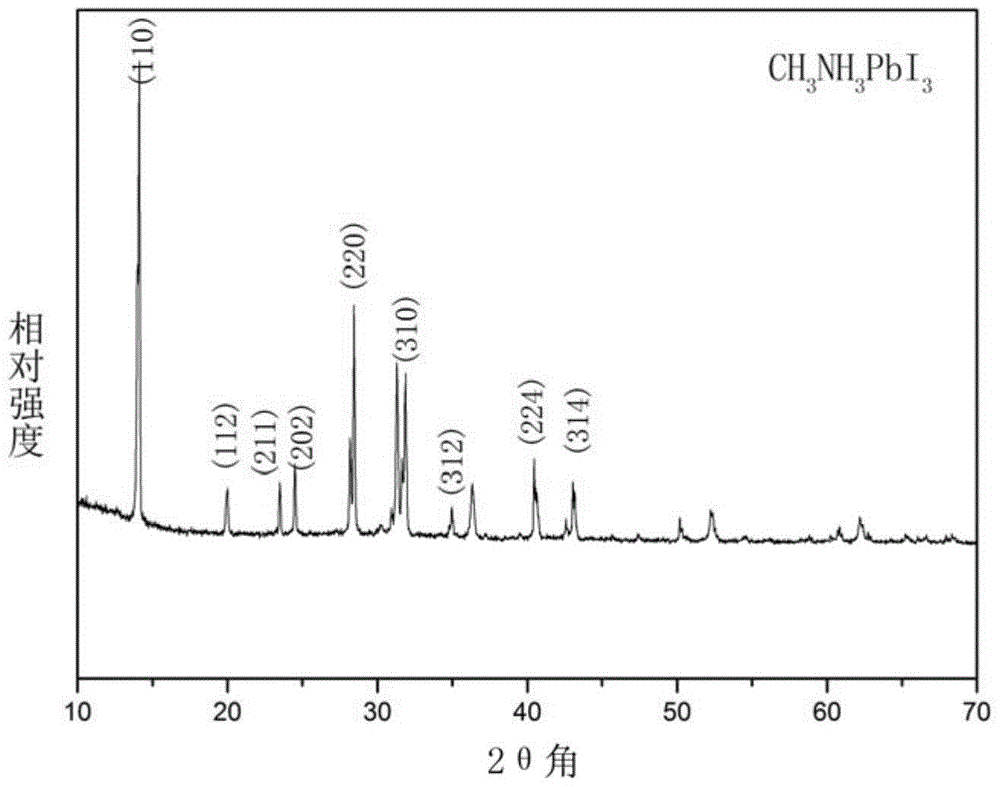

[0044] (1) Preparatory work: ITO conductive glass (Wuhan Auger: 222 crystal plane is the dominant growth crystal plane) in a vacuum of 4~6×10 -3 mbar DC magnetron sputtering a layer of metal lead elemental film with a thickness of about 400nm, and then put it in a desiccator for standby; wash the beaker with tap water and distilled water successively, and dry it for later use;

[0045] (2) Reaction steps: Prepare an anhydrous ethanol solution with a methylamine iodide concentration of 0.0100g / ml and an iodine element concentration of 0.0007g / ml in a beaker, and then place the beaker in a device with temperature control functions such as a biochemical incubator Constant temperature to 15°C, put the glass substrate with the surface of the metal lead elemental film into the reaction solution, and react at 15°C for 1 hour;

[0046] (3) Post-treatment: After the reaction, close the biochemical incubator, take out the sample, and dry it in a blast drying oven at 70°C. Will get CH ...

Embodiment 2

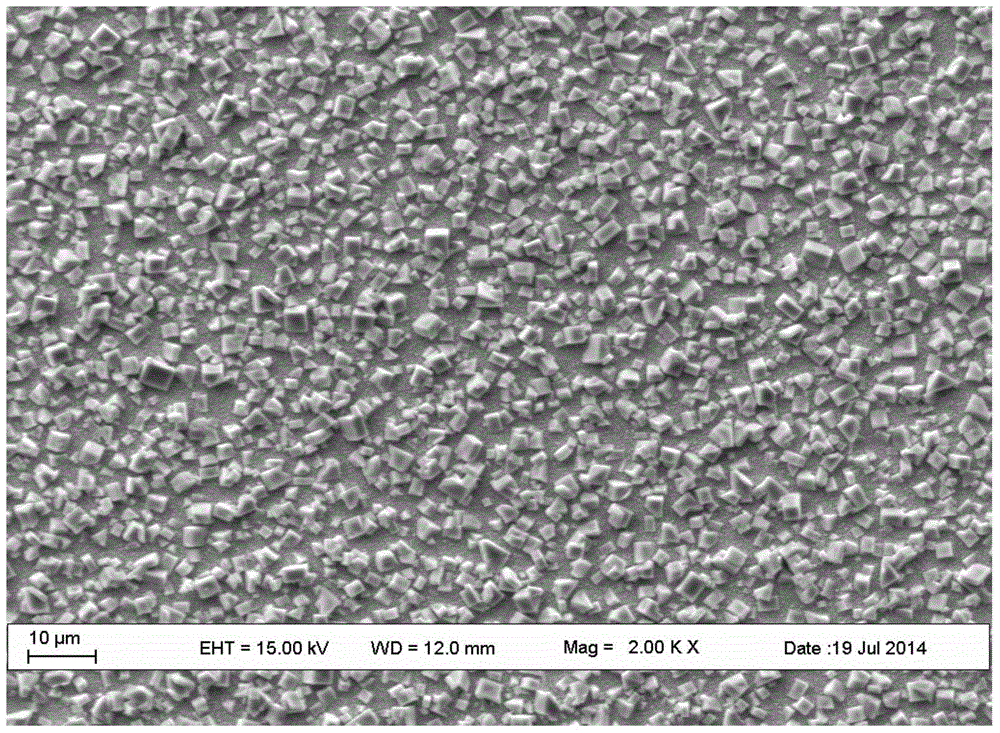

[0048] (1) Preparatory work: ITO conductive glass (Wuhan Aoge, 222 crystal plane is the dominant growth crystal plane) in a vacuum of 4~6×10 -3 mbar DC magnetron sputtering a layer of metal lead elemental film with a thickness of about 400nm, and then put it in a desiccator for standby; wash the beaker with tap water and distilled water successively, and dry it for later use;

[0049] (2) Reaction steps: Prepare an anhydrous ethanol solution with a methylamine iodide concentration of 0.0100g / ml and an iodine element concentration of 0.0007g / ml in a beaker, and then place the beaker in a device with temperature control functions such as a biochemical incubator Constant temperature to 15°C, put the glass substrate with the surface of the metallic lead elemental thin film into the reaction solution, and react at 15°C for 2 hours;

[0050] (3) Post-treatment: After the reaction, close the biochemical incubator, take out the sample, and dry it in a blast drying oven at 70°C. Will ...

Embodiment 3

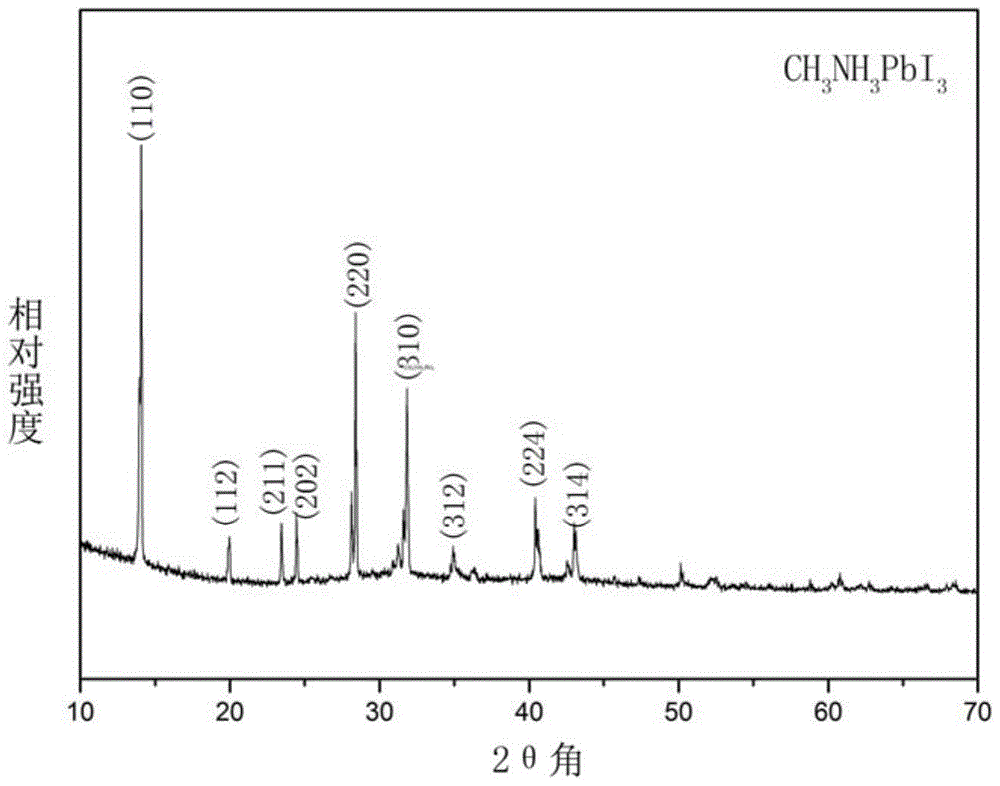

[0052] (1) Preparatory work: ITO conductive glass (Wuhan Aoge, 222 crystal plane is the dominant growth crystal plane) in a vacuum of 4~6×10 -3 mbar DC magnetron sputtering a layer of metal lead elemental film with a thickness of about 400nm, and then put it in a desiccator for standby; wash the beaker with tap water and distilled water successively, and dry it for later use;

[0053] (2) Reaction steps: Prepare an anhydrous ethanol solution with a methylamine iodide concentration of 0.0100g / ml and an iodine element concentration of 0.0007g / ml in a beaker, and then place the beaker in a device with temperature control functions such as a biochemical incubator Constant temperature to 15°C, put the glass substrate with the surface of the metallic lead elemental thin film into the reaction solution, and react at 15°C for 3 hours;

[0054] (3) Post-treatment: After the reaction, close the biochemical incubator, take out the sample, and dry it in a blast drying oven at 70°C. Will ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com