Graphene/gallium arsenide solar cell and manufacturing method thereof

A technology of solar cells and graphene, applied in the field of solar energy, can solve the problems of complex preparation process of gallium arsenide solar cells, difficulty in wide-scale promotion, high cost, etc., achieve high open circuit voltage and conversion efficiency, and be conducive to industrial application , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

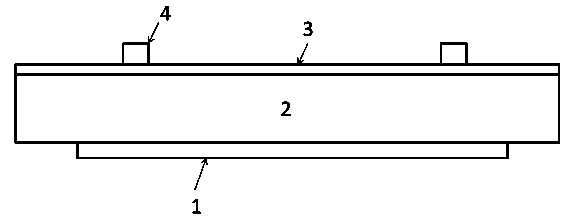

[0021] 1) Deposit a gold electrode on one side of the n-type doped gallium arsenide sheet by electron beam evaporation; then immerse it in 10% NaOH aqueous solution for 1 minute to clean the surface, then take it out and dry it;

[0022] 2) transfer single-layer graphene to the other side of the surface-cleaned gallium arsenide wafer;

[0023] 3) Deposit silver electrodes on graphene by thermal evaporation process to obtain graphene / gallium arsenide solar cells.

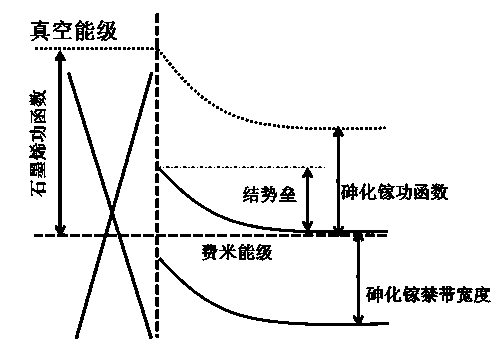

[0024] The basic principle of the resulting graphene / GaAs solar cell is based on the Schottky junction formed by graphene and GaAs, formed by figure 2 The graphene / n-type doped gallium arsenide solar cell energy band schematic diagram shown shows that gallium arsenide has a suitable band gap to convert solar energy into electrical energy, and the work function of graphene is greater than that of n-type doped gallium arsenide The work function of the two materials will form a Schottky junction when they are in conta...

Embodiment 2

[0026] 1) Deposit a palladium electrode on one side of the p-type doped gallium arsenide sheet by magnetron sputtering; then immerse in 20% HCl aqueous solution for 15 minutes to clean the surface, and then take it out and dry it;

[0027] 2) Transfer 10 layers of graphene to the other side of the surface-cleaned GaAs wafer;

[0028] 4) Deposit nickel electrodes on graphene by thermal evaporation process to obtain graphene / gallium arsenide solar cells.

Embodiment 3

[0030] 1) Deposit a chromium / titanium electrode on one side of an n-type doped gallium arsenide wafer using a pulsed laser; then immerse it in HNO with a mass concentration of 10% 3 Clean the surface in the aqueous solution for 30 minutes, then take it out and blow dry;

[0031] 2) Transfer 2 layers of graphene to the other side of the surface-cleaned GaAs wafer;

[0032] 3) Screen-print silver electrodes on graphene to obtain graphene / gallium arsenide solar cells.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com