A kind of antifreeze method for exhaust pipeline of molten salt solar heat absorber

A technology for solar heat absorbers and exhaust pipelines, applied in the field of heat absorber pipelines, can solve the problems of high power consumption of heat tracing, etc., and achieve the effect of reducing parasitic power consumption and avoiding blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

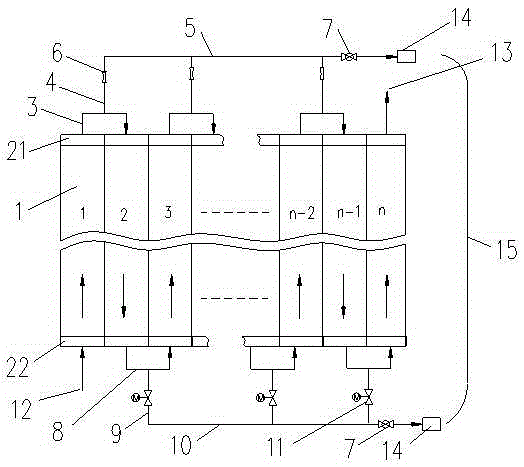

[0027] Such as figure 1 As shown, a method for antifreezing of the exhaust pipeline of a molten salt solar heat absorber. The heat absorber 15 is formed by connecting 1 to n levels of heating surfaces in series, wherein the value of n depends on the heat capacity of the heat absorber. Decide. The top connecting pipe 3 at the top of the heat absorber and the bottom connecting pipe 8 at the bottom of the heat absorber connect the adjacent two-stage heating surfaces with each other, so that the heating surfaces of the heat absorber 15 at all levels are connected in series to form a "bow"-shaped circuit; specifically In other words, the "bow" shaped circuit means: the top of the heat receiving surface 1 of the heat absorber is the top header 21 of the heat receiving surface, the bottom of the heat receiving surface of the heat absorber is the bottom header 22 of the heat receiving surface, and the inlet of the heat absorber 12 is located at the bottom of the bottom header 2 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com