Tail gas treatment system of fuel cell and control method

A tail gas treatment and fuel cell technology, applied in fuel cells, electrical components, circuits, etc., can solve the problems of low hydrogen utilization, reduce parasitic power consumption, and solve the risk of explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

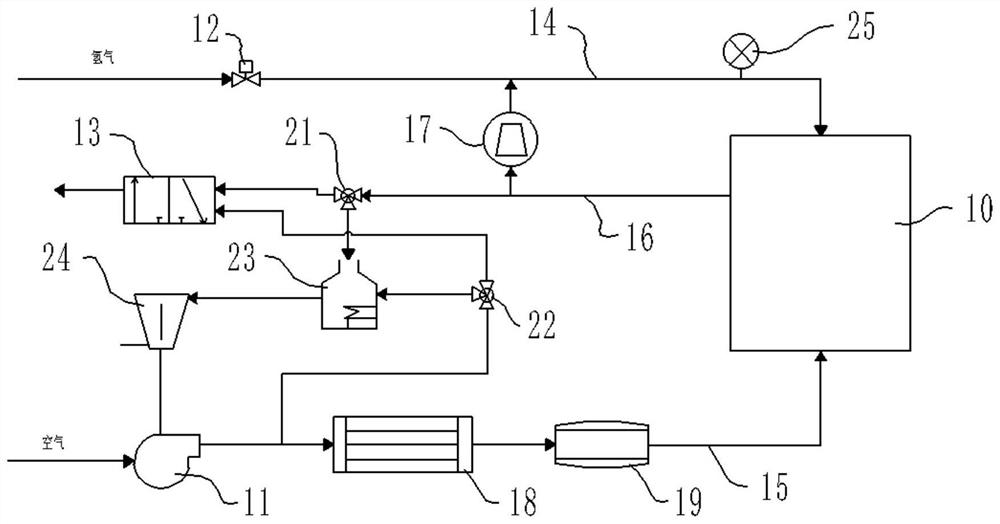

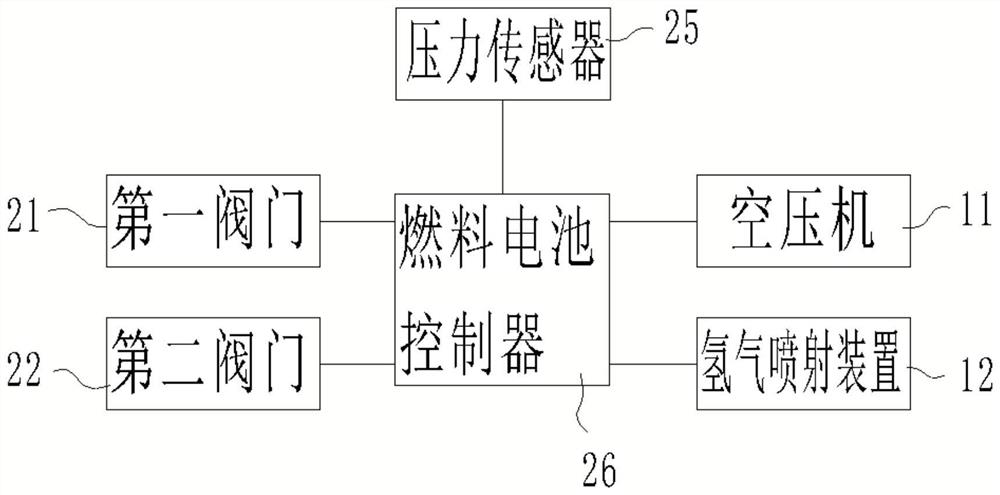

[0056] like figure 1 As shown, the fuel cell includes a stack 10 , an air compressor 11 , a hydrogen injection device 12 and a tail exhaust 13 .

[0057] The stack 10 is the core component of the fuel cell, and the anode hydrogen inlet of the stack 10 is connected to the hydrogen injection device 12 through the hydrogen inlet pipeline 14, so as to deliver the hydrogen required for the electrochemical reaction in the stack 10 through the hydrogen injection device 12; The cathode air inlet of the stack 10 is connected to the air compressor 11 through the air inlet pipe 15 to convey the oxygen required for the electrochemical reaction to the stack 10 through the air compressor 11 , and the oxygen contains the compressed air delivered by the air compressor 11 in the air. The anode hydrogen outlet of the stack 10 is connected to the tail row 13 through a hydrogen discharge pipeline 16 , so that the unreacted but remaining hydrogen in the stack 10 is discharged through the tail row...

Embodiment 2

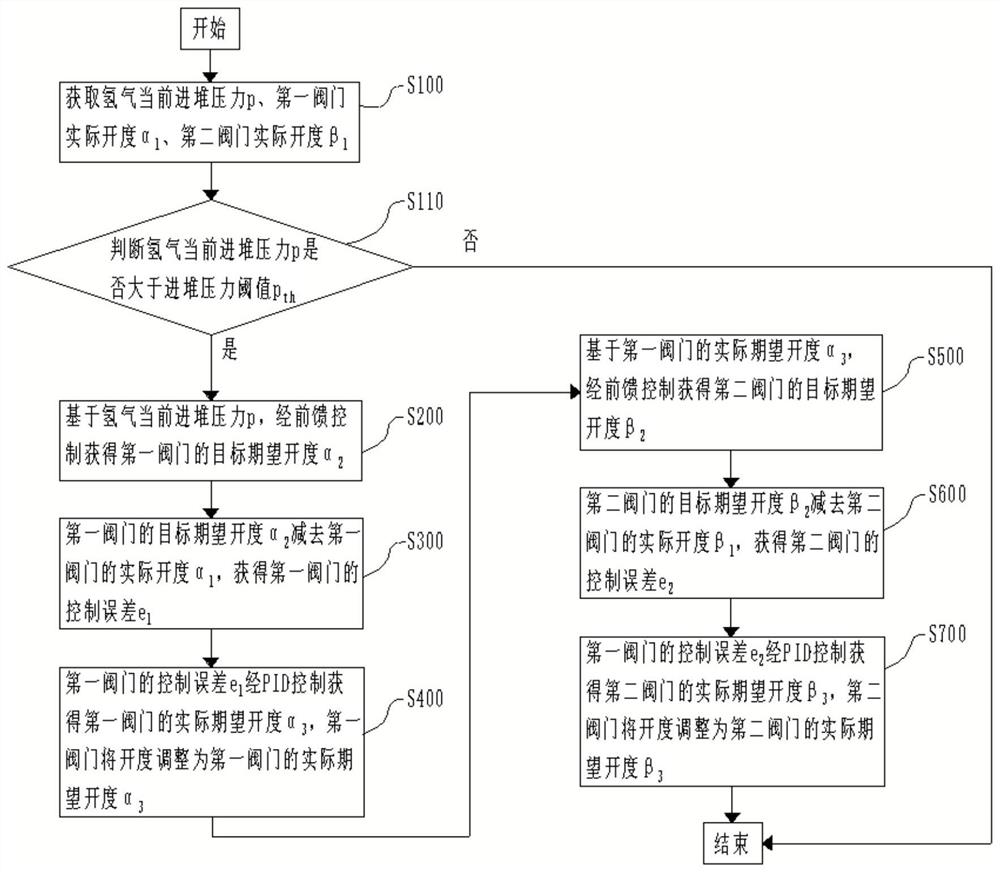

[0096] like image 3 , Figure 7 , Figure 8 as well as Figure 9 As shown, this embodiment also provides another control method for the exhaust gas treatment system of the fuel cell, and the control method includes the following steps:

[0097] S100: The fuel cell controller 26 obtains the current pressure p of hydrogen in the hydrogen inlet pipeline 14 of the stack, and the actual opening degree α of the first valve 211 1 and the actual opening β of the second valve 22 1 . Among them, the actual opening degree α of the first valve 21 1 It is obtained through the opening sensor on the first valve 21 and transmitted to the fuel cell controller 26 through a hard-wired signal; the actual opening β of the second valve 22 1 It is obtained through the opening sensor on the second valve 22, and is transmitted to the fuel cell controller 26 through a hard-wired signal; the current pressure p of hydrogen into the stack is obtained through the pressure sensor 25 set on the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com