Micro-flow valve and direct liquid fuel battery fuel supply system

A micro-flow, flow valve technology, applied in fuel cells, fuel cell additives, fuel cell control and other directions, can solve the problems of high cost and difficult to reduce costs, improve efficiency, ensure safety, reduce parasitic power consumption and manufacturing cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

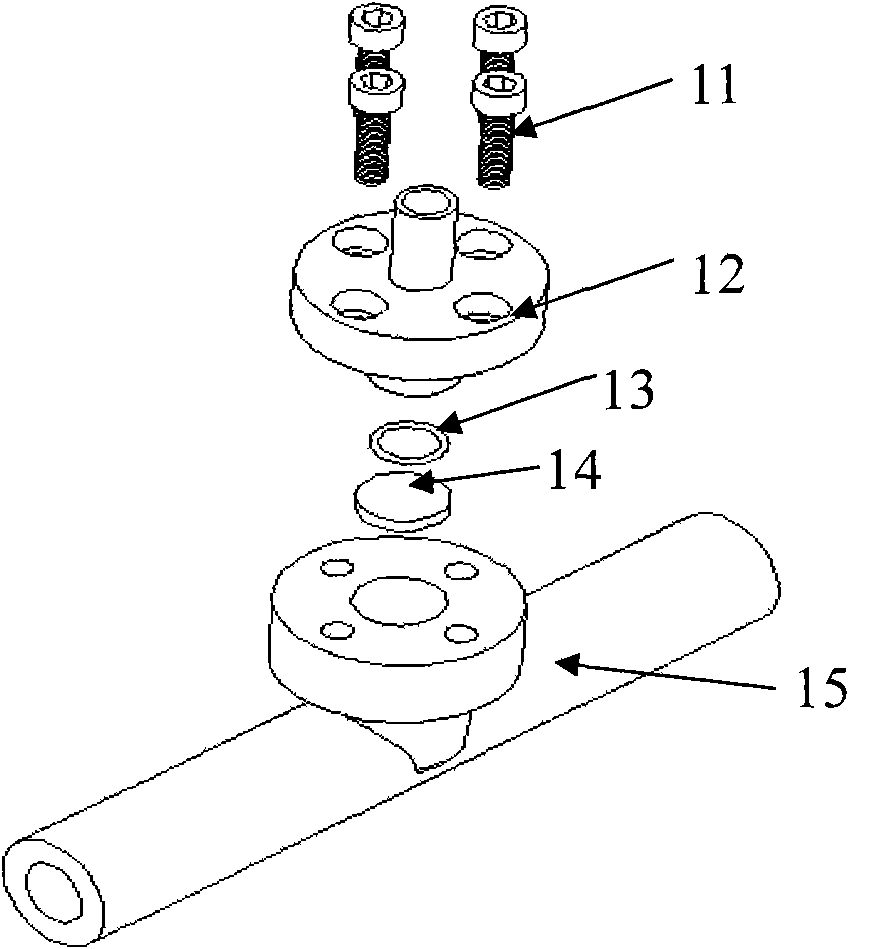

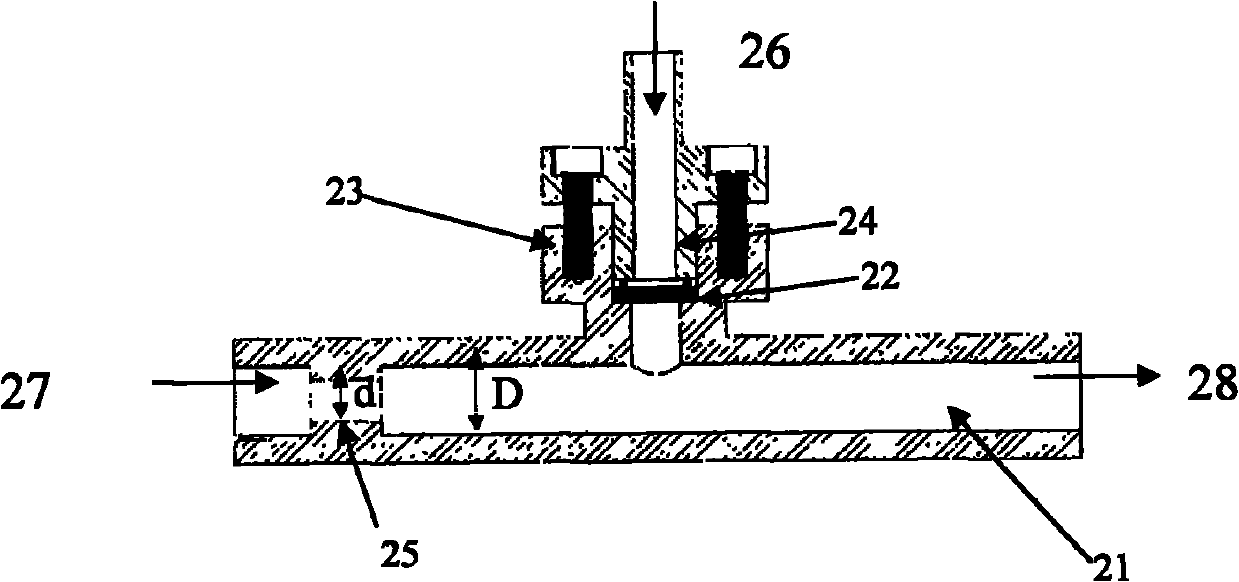

[0034] A liquid micro flow valve, its structure is as figure 1 with figure 2 shown. It is mainly composed of four parts: fuel inlet valve body 12 , sealing ring 13 , microporous membrane 14 , and fuel outlet valve seat 15 . The microporous membrane 14 is placed at the bottom of the side branch concave hole 22 of the valve seat 15, the fuel inlet valve body 12 is buckled on the flange 23 of the valve seat 15 by the screw 11, and the raised stop 24 of the fuel inlet valve body 12 is pressed The sealing ring 13 realizes the sealing between the microporous membrane, the valve seat and the valve body stop. The main pipe 21 of the valve seat 15 communicates with the flange 23, and the inlet of the main pipe 21 is provided with a section of throat pipe 25 to increase the liquid suction resistance of the inlet.

[0035] The microporous membrane used in the above-mentioned liquid micro-flow valve is non-hydrophilic, such as PVDF membrane and PTFE membrane, the pore diameter of whic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com