Preparation method of universal type polyester staple fiber oil

A general-purpose polyester staple fiber technology, applied in fiber treatment, fiber type, textiles and papermaking, etc., can solve problems such as unstable oil emulsion and strong irritating smell of oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

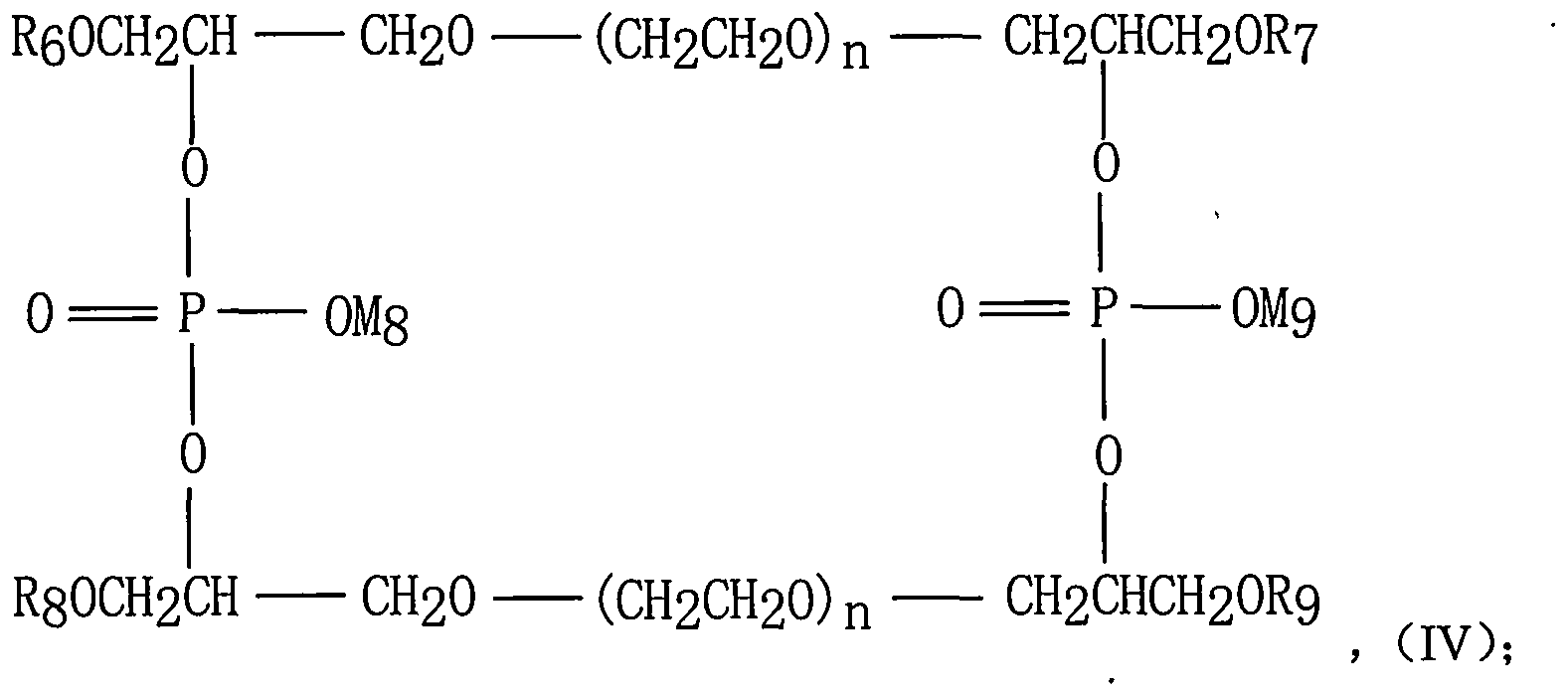

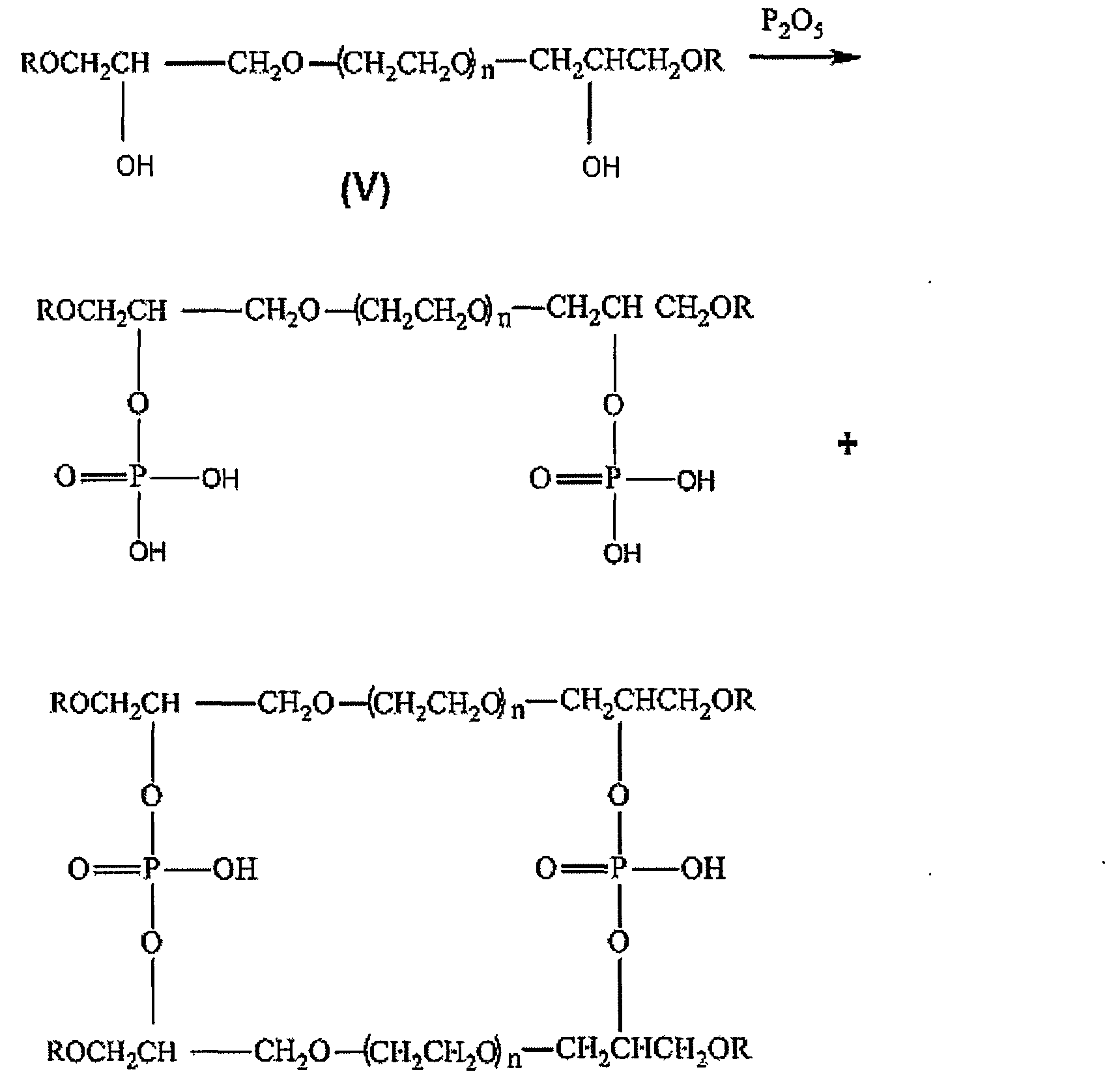

Method used

Image

Examples

Embodiment 1

[0060] 1. Oil formulation and preparation of oil emulsion

[0061] Each component in the following oil formula is mixed uniformly, and then the obtained mixture is formulated with deionized water to be an oil emulsion with an effective substance concentration of 0.2wt%:

[0062] Potassium cetyl phosphate, 1 part;

[0063] Potassium lauryl polyethylene glycol (3) Gemini phosphate, 1 part;

[0064] Nonylphenol polyoxyethylene (9) ether, 0.8 parts;

[0065] Polyoxyethylene (10) laurate, 0.5 parts.

[0066] For ease of comparison, the composition of the oil formulation is listed in Table 1.

[0067] 2. Preparation of oily fiber samples

[0068] At room temperature, immerse 20 grams of oil-free silk in 200 grams of the oil emulsion prepared in step 1 for 5 minutes, then centrifuge in a centrifuge for 3 minutes, take out the silk and dry it in an oven at 110 ° C for 4 hours, then dry it at 25 ° C , Cool in 65RH% environment to obtain the required oil-containing fiber sample. T...

Embodiment 2

[0115] Except adopting following oil formulation, other operation steps are all identical with embodiment 1:

[0116] Potassium cetyl phosphate, 1 part;

[0117] Octyl polyethylene glycol (3) potassium salt of Gemini phosphate, 1 part;

[0118] Nonylphenol polyoxyethylene (9) ether, 0.8 parts;

[0119] Polyoxyethylene (10) laurate, 0.5 parts.

[0120] For ease of comparison, the composition of the oil formulation is listed in Table 1, and the test results are listed in Table 2 and Table 3.

Embodiment 3

[0122] Except adopting following oil formulation, other operation steps are all identical with embodiment 1:

[0123] Potassium cetyl phosphate, 1 part;

[0124] Cetyl polyethylene glycol (3) potassium salt of Gemini phosphate, 1 part;

[0125] Nonylphenol polyoxyethylene (9) ether, 0.8 parts;

[0126] Polyoxyethylene (10) laurate, 0.5 parts.

[0127] For ease of comparison, the composition of the oil formulation is listed in Table 1, and the test results are listed in Table 2 and Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com