A kind of pure odor wear-resistant ultraviolet light curing coating and preparation method thereof

A technology of ultraviolet light and coating, applied in the direction of coating, etc., can solve the problems of poor scratch resistance and wear resistance of the coating film, and achieve the effects of good yellowing resistance, good adhesion, and excellent leveling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

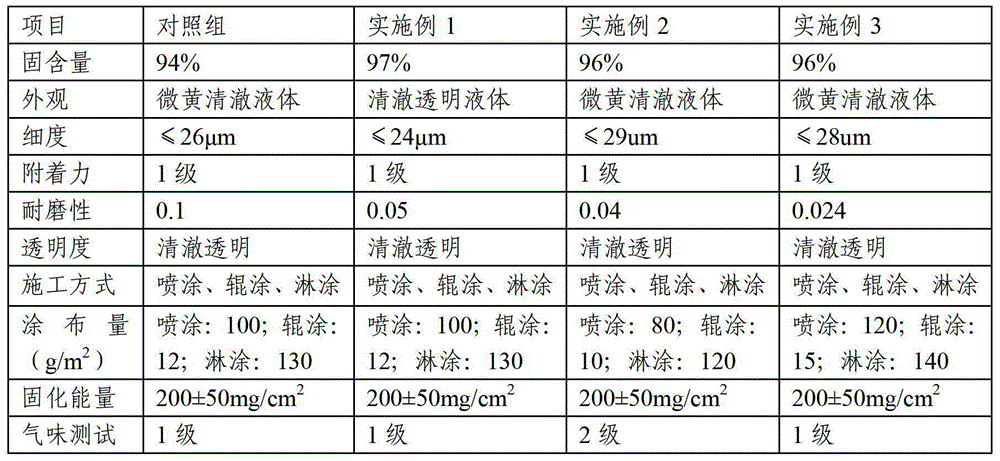

Examples

Embodiment 1

[0049] Embodiment 1: clean odor wear-resistant UV light-cured coating

[0050] 1. The weight percentage of raw materials is shown in Table 1:

[0051] composition

Weight (kg)

Weight percentage (%)

ZC-5601 UV curable resin

50.2

50.2

Reactive acrylate monomer THFA

44

44

Photoinitiator 1-Hydroxycyclohexyl phenyl ketone

4.0

4.0

Defoamer BYK-055

0.5

0.5

Leveling agent TEGO-410

0.3

0.3

Wetting and dispersing agent BYK-P-104

1.0

1.0

total

100

100

[0052] 2. Preparation method:

[0053] 1) First, stir ZC-5601 and THFA evenly, then disperse for 22 minutes with a disperser (Yixing Jingyi Machinery GFJ-B-75Kw);

[0054] 2) Then add BYK-P-104 and TEGO-410 to disperse at a medium speed for 10 minutes under stirring, and disperse for 20 minutes after stirring evenly.

[0055] 3) Then add defoamer and photoinitiator to disperse for 10 minutes, that is.

Embodiment 2

[0056] Embodiment 2: clean odor wear-resistant UV light-cured coating

[0057] 1. The weight percentage of raw materials is shown in Table 2:

[0058] Table 2: Raw material ratio of embodiment 2

[0059] composition

Weight (kg)

Weight percentage (%)

ZC-5601 UV curable resin

42

42

Reactive acrylate monomer THFA

52.2

52.2

Photoinitiator 1-Hydroxycyclohexyl phenyl ketone

4.0

4.0

Defoamer BYK-055

0.5

0.5

Leveling agent TEGO-410

0.3

0.3

Wetting and dispersing agent BYK-P-104

1.0

1.0

total

100

100

[0060] 2. Preparation method:

[0061] 1) First, stir ZC-5601 and THFA evenly and disperse at high speed for 25 minutes;

[0062] 2) Then add BYK-P-104 and TEGO-410 to disperse at a medium speed for 10 minutes under stirring, then add the photoinitiator into the stirring disperser, stir evenly and disperse for 10 minutes;

[0063] 3) Then add defoamer to dis...

Embodiment 3

[0064] Embodiment 3: clean odor wear-resistant UV light-cured coating

[0065] 1. The weight percentage of raw materials is shown in Table 3:

[0066] Table 3: Raw material ratio of embodiment 3

[0067] composition

Weight (kg)

Weight percentage (%)

ZC-5601 UV curable resin

60

60

Reactive acrylate monomer THFA

34.2

34.2

Photoinitiator 1-Hydroxycyclohexyl phenyl ketone

4.0

4.0

Defoamer BYK-055

0.5

0.5

Leveling agent TEGO-410

0.3

0.3

Wetting and dispersing agent BYK-P-104

1.0

1.0

total

100

100

[0068] 2. Preparation method:

[0069] 1) First, stir ZC-5601 and THFA evenly and disperse for 20 minutes;

[0070] 2) Then add BYK-P-104 and TEGO-410 to disperse at a medium speed for 10 minutes under stirring, then add the photoinitiator into the stirring disperser, stir evenly and disperse at a high speed for 10 minutes;

[0071] 3) Then add BYK-055 and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com