Hot-rolled wire rod for manufacturing high-strength steel strand of strong and smart grid and production method of hot-rolled wire rod

A technology of hot-rolled wire rod and production method, which is applied in metal rolling and other directions, and can solve problems such as inability to meet high requirements, increased strength, and brittle fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

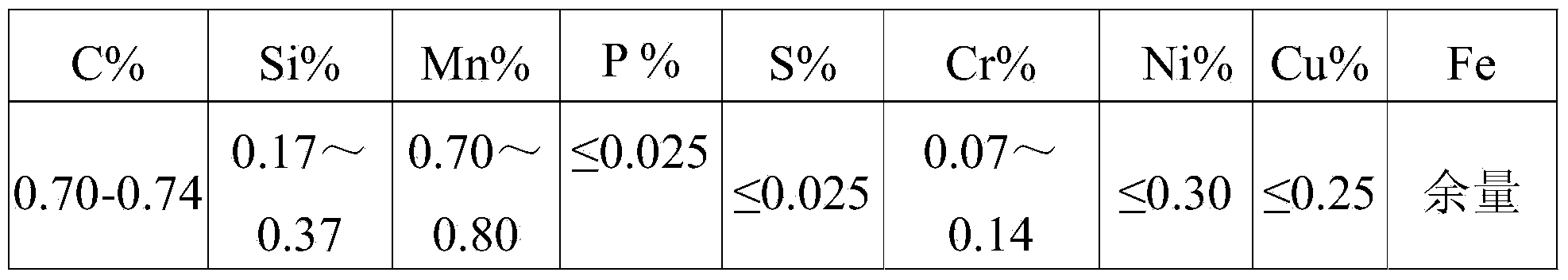

[0078] The hot-rolled wire rod used in the manufacture of high-strength rare-earth galvanized steel strands for smart and strong power grids, its chemical composition consists of the following substances by weight percentage (%): C0.70%, Si0.22%, Mn0.72%, Cr 0.08% . The shrinkage rate is 49%, and the elongation rate is 19%, listed in Table 2.

[0079] A production method for manufacturing hot-rolled wire rods for high-strength rare-earth galvanized steel strands for intelligent strong grids is carried out in the following steps:

[0080] 1. Smelting

[0081] Using converter or electric furnace for smelting, tapping end point control: [C] ≥ 0.08%, [P] ≤ 0.015%, [S] ≤ 0.020%; tapping temperature: 1640-1690°C; double slag blocking process: before tapping Add slag stopper, add slag stop rod or slag stop cone when tapping 4 / 5; add alloy and recarburizer along with steel flow, alloy addition time: start to add when tapping 1 / 5, add before tapping 4 / 5 The recarburizer must be adde...

Embodiment 2

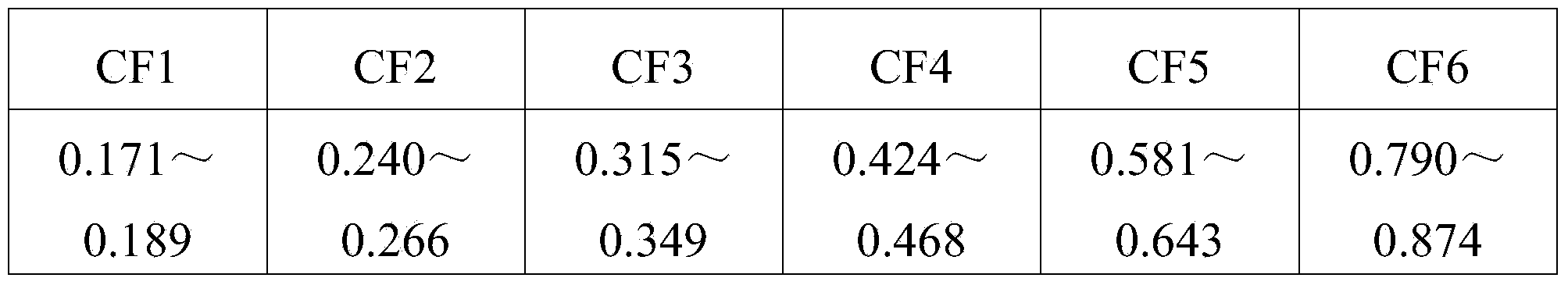

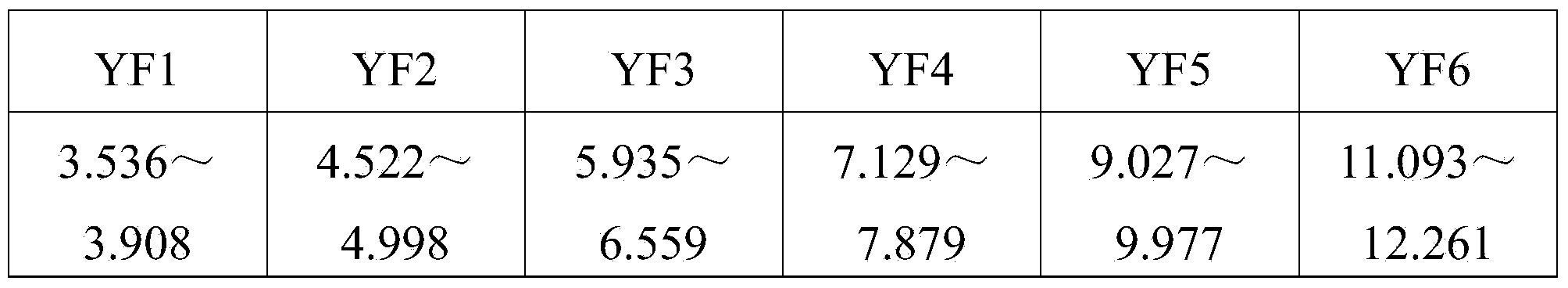

[0126] With the method of Example 1, the chemical composition is listed in Table 1, the properties are listed in Table 2, and the rolling process parameters are listed in Tables 3-22 respectively.

Embodiment 3

[0128] With the method of Example 1, the chemical composition is listed in Table 1, the properties are listed in Table 2, and the rolling process parameters are listed in Tables 3-22 respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com