Composite surface active agent composition for tertiary oil recovery and preparation method and application thereof

A surfactant and composition technology, applied in the field of surfactant composition, can solve problems such as poor oil displacement efficiency, difficulty in demulsification of corroded equipment and pipelines, damage to formations and oil wells, etc., to improve oil displacement efficiency and avoid damage , to overcome the effect of cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

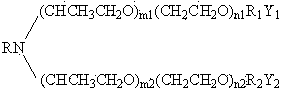

Method used

Image

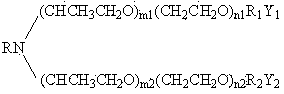

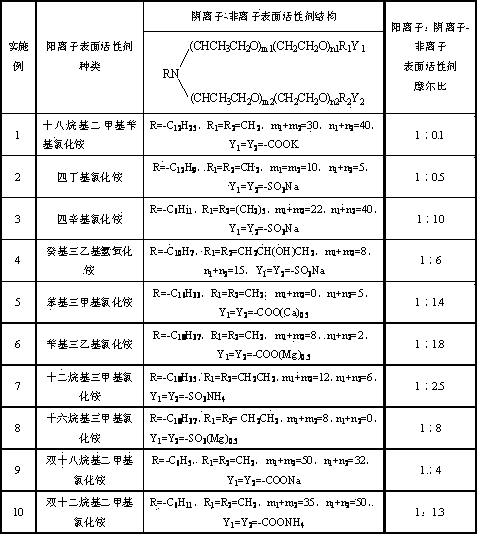

Examples

Embodiment 1

[0032] Add dodecylamine and KOH to the reaction kettle according to the molar ratio of 1:2, stir for 30 minutes, then add the required amount of propylene oxide, at 200 o C reacted for 1 hour, then added the required amount of ethylene oxide, at 160 o C reaction for 3 hours; finally add chloroacetic acid according to the molar ratio of dodecylamine to carboxylation reagent 1:1, at 50 o C continued to react for 20 hours. After the reaction, the pH was adjusted to 1 with 5wt% hydrochloric acid aqueous solution, and the mixture was allowed to stand and separate into layers. The water phase was separated, the oil phase was adjusted to pH=8 with 10wt% KOH aqueous solution, and the water was evaporated in vacuo to obtain an anionic-nonionic surfactant.

[0033] Octadecyl dimethyl benzyl ammonium chloride and the anion-nonionic surfactant prepared by the present invention were dissolved in water respectively, stirred for 30 minutes, and mixed with a 0.3 wt % aqueous solution, and ...

Embodiment 2

[0036] Add o-phenylaniline and NaOH into the reaction kettle according to the molar ratio of 1:6, stir for 30 minutes, add the required amount of ethylene oxide, at 160 o C reacted for 3 hours, then added the required amount of ethylene oxide, at 160 o C was reacted for 7 hours; finally, sodium chloromethanesulfonate was added according to the molar ratio of o-phenylaniline and sulfonating reagent 1:8, at 120 o C continued to react for 14 hours. After the reaction, the pH was adjusted to 2 with 5wt% hydrochloric acid aqueous solution, and the mixture was allowed to stand and separate into layers. The water phase was separated, the oil phase was adjusted to pH=9 with 10wt% NaOH aqueous solution, and the water was evaporated in vacuo to obtain an anionic-nonionic surfactant.

[0037] Tetrabutylammonium chloride and the anionic-nonionic surfactant prepared by the present invention were respectively dissolved in water, stirred for 30 minutes, and formulated into a 0.3 wt % aque...

Embodiment 3

[0040] Add cyclohexylamine and NaOH to the reaction kettle according to the molar ratio of 1:4, stir for 30 minutes, add the required amount of propylene oxide, at 100 o C reacted for 20 hours, then added the required amount of oxirane, at 150 o C was reacted for 8 hours; finally, 5-chloro-pentanesulfonate sodium was added according to the molar ratio of cyclohexylamine to sulfonating reagent 1:2.5, at 120 o C continued to react for 14 hours. After the reaction, the pH was adjusted to 2 with 5wt% hydrochloric acid aqueous solution, and the mixture was allowed to stand and separate into layers. The water phase was separated, the oil phase was adjusted to pH=9 with 10wt% NaOH aqueous solution, and the solvent was removed in vacuo to obtain an anionic-nonionic surfactant.

[0041] Tetraoctyl ammonium chloride and the anionic-nonionic surfactant prepared by the present invention were respectively dissolved in water, stirred for 30 minutes, and formulated into a 0.3 wt % aqueous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com