A Method for Improving the Density of Parallel Arrays of Carbon Nanotubes Using Elastic Material Poisson's Ratio

A technology of carbon nanotubes and elastic materials, which is applied in the direction of nanotechnology, nanotechnology, and nanotechnology for materials and surface science, and can solve the problems of increasing the density of carbon nanotube arrays, winding and bending of carbon nanotubes, and loss of carbon nanotube density and other problems, to achieve the effect of easy growth, not easy to remove, and uniform density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] PMMA is selected as the elastic material.

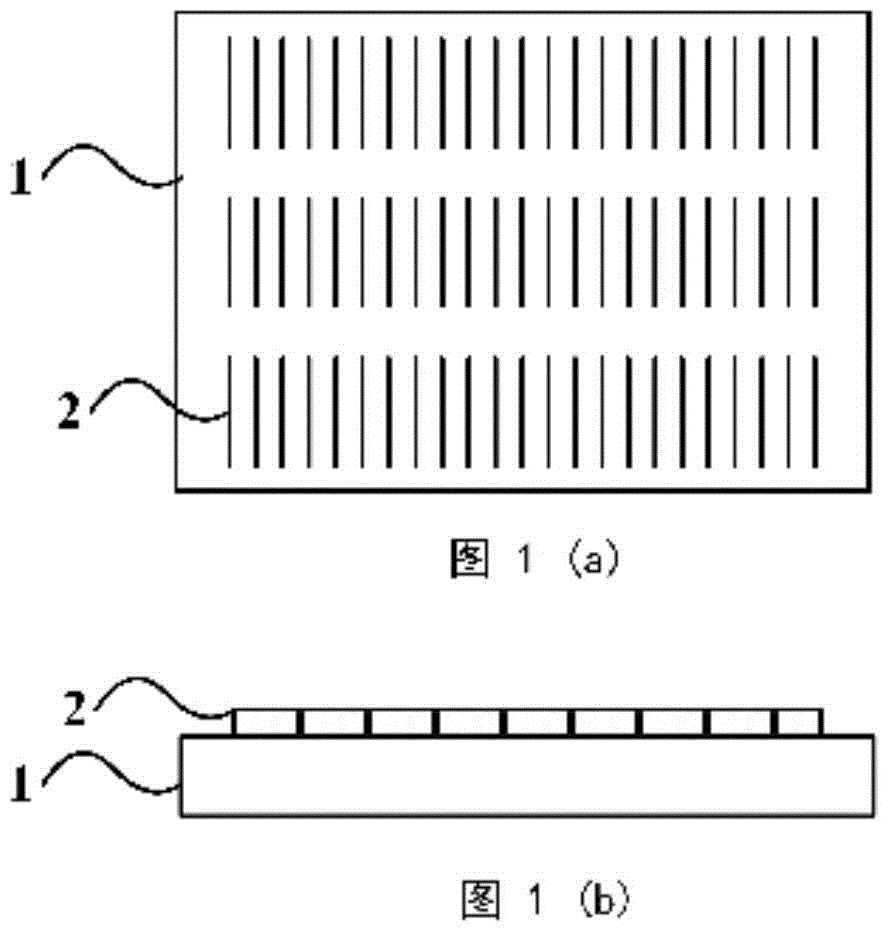

[0039] 1. A parallel array of carbon nanotubes 2 is grown on a quartz substrate 1 by CVD (as shown in Figure 1 (a) and (b)); the catalyst used in the CVD growth method with a quartz plate as the substrate is usually CuCl 2 solution, FeCl 3 Metal elemental Fe deposited by solution and electron beam evaporation coating. The growth carbon source is usually CH 4 、C 3 h 7 OH et al.

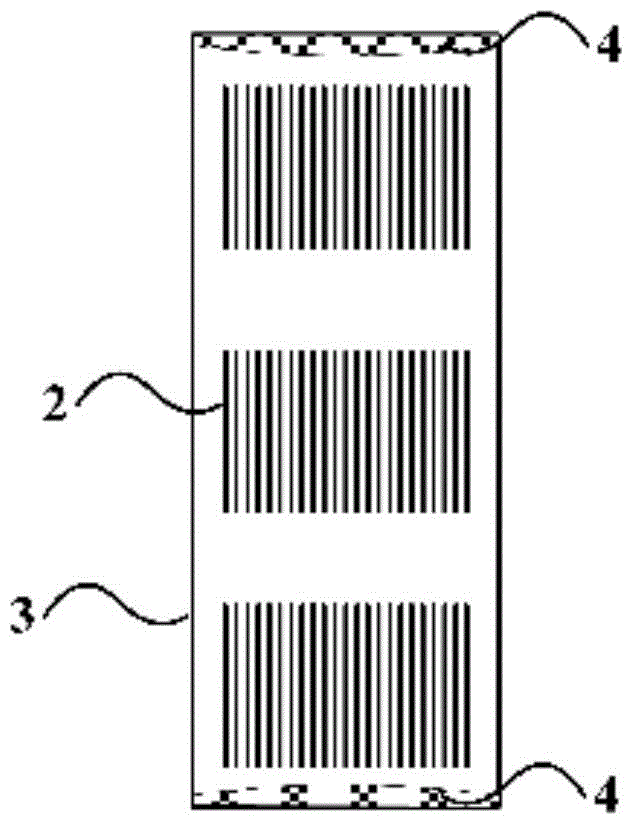

[0040]2, the gained carbon nanotube array is transferred to elastic material 3---on PMMA (as Fig. 2): (1) on the quartz substrate 1 that has grown carbon nanotube parallel array 2, spin-coat PMMA600K, uniform glue speed 2000rad / s, as shown in Figure 2(a). After natural drying, paste the PET blue film 4 on both sides of the carbon tube extension direction. The blue film here is a commonly used material for microelectronics. It is immersed in HFBuffer (7:1) solution to etch the quartz substrate 1 (SiO 2 ), the corrosion was completed in about 48 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com