A kind of injection molding alloy powder and its application in automobile gearbox sliding sleeve

An automotive gearbox and injection molding technology, which is applied to belts/chains/gears, mechanical equipment, transmission parts, etc., can solve the problem of limited accuracy of temperature and atmosphere control, sliding sleeves that cannot be used in technical processes, and unstable strengthening phase content, etc. problems, to achieve the effect of optimizing the sintering process, expanding the temperature of the sintering interval, and improving the stability of tempering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The preparation of the automobile gearbox sliding sleeve by injection molding alloy powder comprises the following steps:

[0048] Step 1: Preparation of feed

[0049] The selected alloy powder components are: C0.40, Si0.35, Mo0.7, Cr1.8, Mn0.6, B1.5, the balance is Fe, and the gas-atomized alloy powder with an alloy powder particle size of 8-10 μm, Mix in a mixer according to the mass ratio of alloy powder and binder 85:15, and mix for 30 minutes at 120-125°C to obtain the feed; the speed of the mixer is 60 rpm, and the mixing time is 2 hours;

[0050] Step Two: Injection Molding

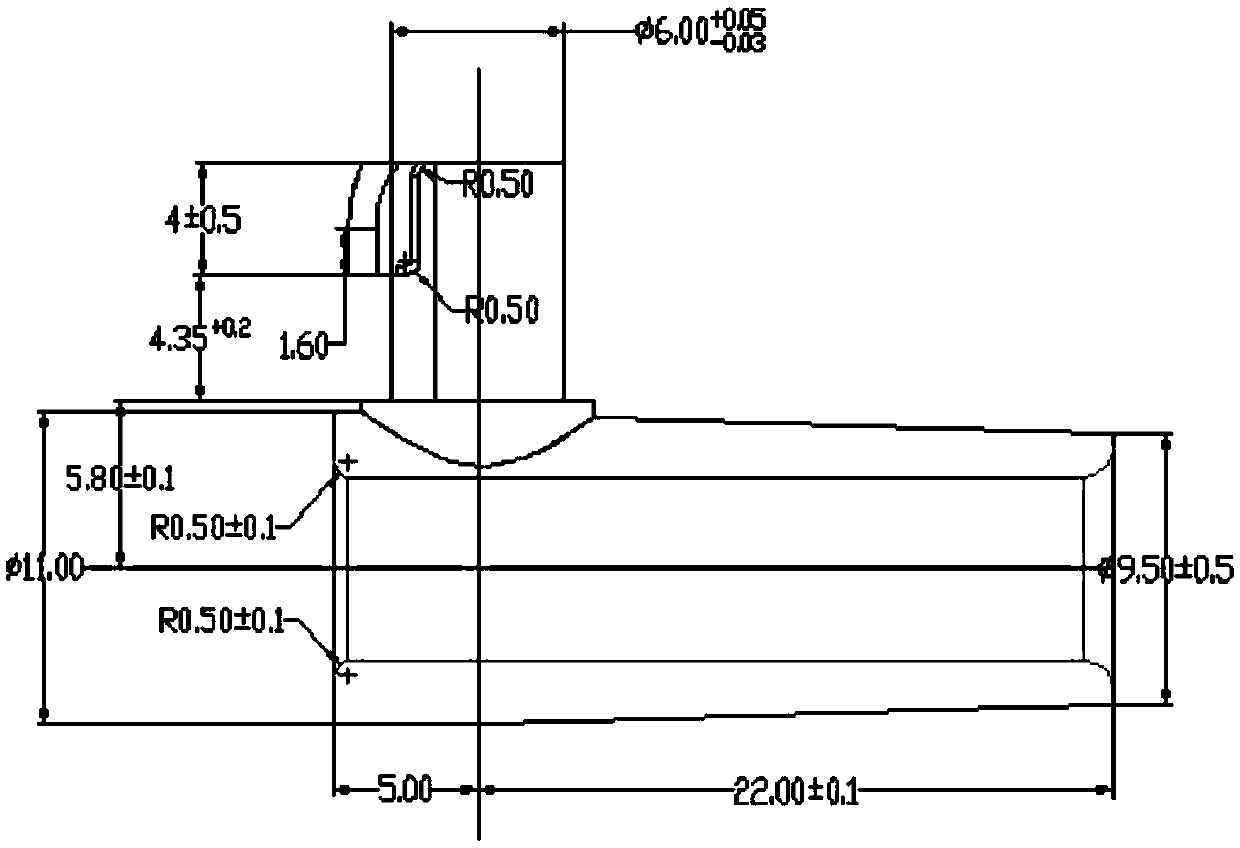

[0051] The feed obtained in the first step is injected into the mold of the automobile gearbox sliding sleeve through the injection molding machine, and the mold is released to obtain the blank of the automobile gearbox sliding sleeve; the injection molding process parameters are: injection temperature 145°C, injection pressure 85MPa, mold The temperature is 50°C; the powder loading is 56%...

Embodiment 2

[0058] The preparation of the automobile gearbox sliding sleeve by injection molding alloy powder comprises the following steps:

[0059] Step 1: Preparation of feed

[0060] The selected alloy powder components are: C0.42, Si0.29, Mo0.76, Cr1.67, Mn0.67, B1.0, the balance is Fe, and the particle size of the alloy powder is 10-15μm. According to the mass ratio of alloy powder and binder 88:12, mix in a mixer, and mix for 50 minutes at 130-140°C to obtain the feed; the speed of the mixer is 150 rpm, and the mixing time is 1.5h ;

[0061] Step Two: Injection Molding

[0062] The feed obtained in the first step is injected into the mold of the automobile gearbox sliding sleeve through the injection molding machine, and the mold is released to obtain the blank of the automobile gearbox sliding sleeve; the injection molding process parameters are: injection temperature 155 ° C, injection pressure 100 MPa, mold The temperature is 55°C; the size of the powder loading is 60%;

[0...

Embodiment 3

[0069] The preparation of the automobile gearbox sliding sleeve by injection molding alloy powder comprises the following steps:

[0070] Step 1: Preparation of feed

[0071] The selected alloy powder components are: C0.45, Si0.25, Mo0.8, Cr1.6, Mn0.8, B0.8, the balance is Fe, and the gas-atomized alloy powder with an alloy powder particle size of 15-20 μm, According to the mass ratio of alloy powder and binder 90:10, mix in a kneader, knead for 45 minutes at 140-150°C to get the feed; the speed of the kneader is 200 rpm, and the kneading time is 0.8h ;

[0072] Step Two: Injection Molding

[0073] The feed material obtained in the first step is injected into the mold of the automobile gearbox sliding sleeve through the injection molding machine, and the mold is released to obtain the blank of the automobile gearbox sliding sleeve; the injection molding process parameters are: injection temperature 170°C, injection pressure 120MPa, mold The temperature is 60°C; the powder l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com