Inoculant particle screening equipment

A technology for screening equipment and inoculants, which is applied in the field of inoculant particle screening equipment, can solve problems such as high cost, low production efficiency, and failure to achieve inoculation effects, and achieve a high degree of automation and increase work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

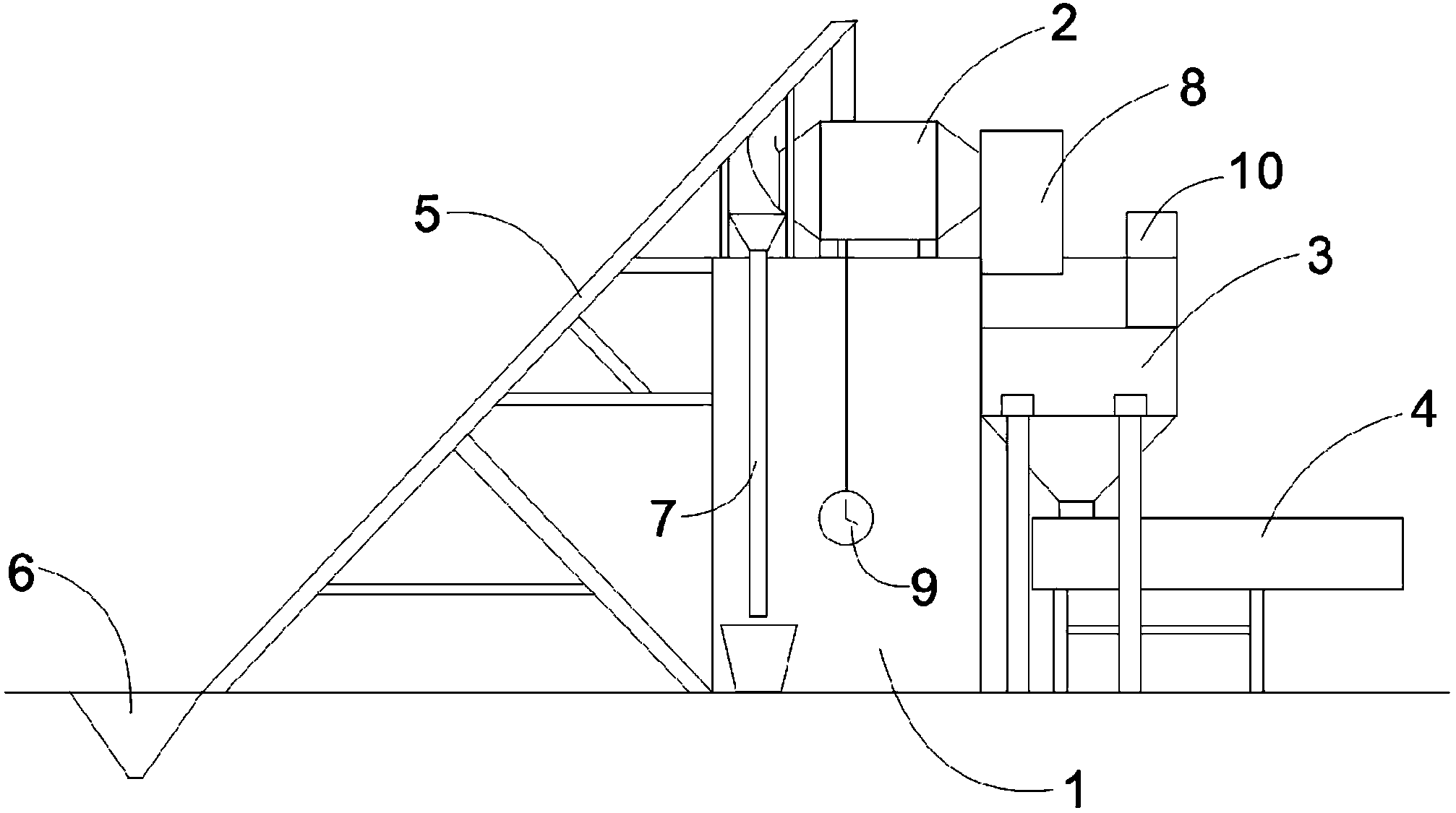

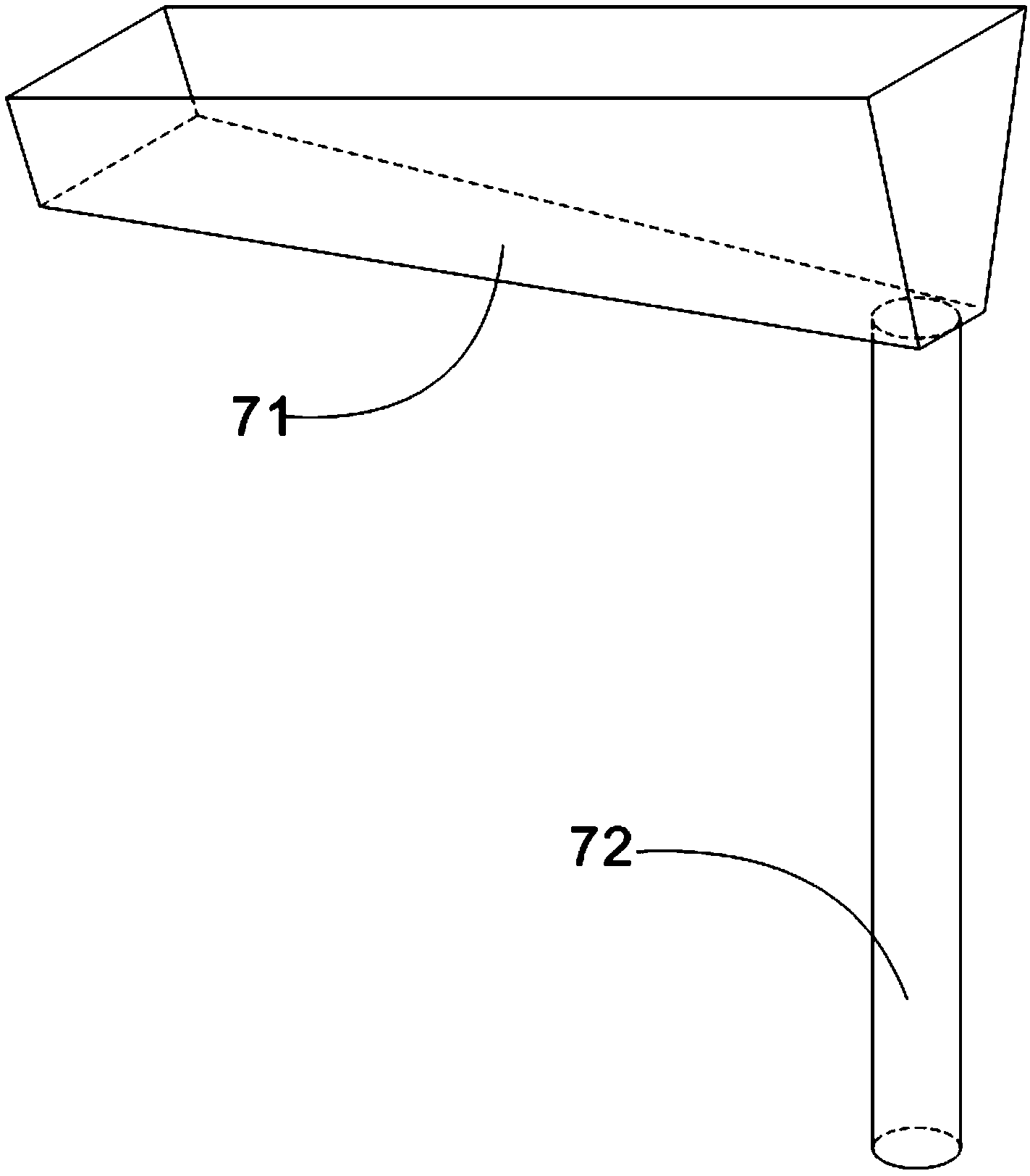

[0024] Such as Figure 1 to Figure 7 As shown, the inoculant particle screening equipment of the present invention includes a platform 1, a mixing tank 2, a storage bin 3, a vibrating screen 4, a frame 5, a hopper 6, a recovery device 7, a discharge channel 8 and a timer 9; The silo 3 comprises a silo cover 31, a silo body 32, a silo bottom 33, a discharge port 34 and a support 35, the silo cover 31 and the silo bottom 33 are respectively located at the upper and lower ends of the silo body 32, and the discharge port 34 is located at the bottom of the storehouse 33. Bottom, warehouse cover 31 tops are provided with breach, and support 35 is installed on warehouse body 32 both sides, and the volume of storage bin 3 is preferably 2m 3 , which can ensure continuous production without stopping the machine; the mixing tank 2 is installed above the platfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com