Method for processing instant flavor crisp little fish

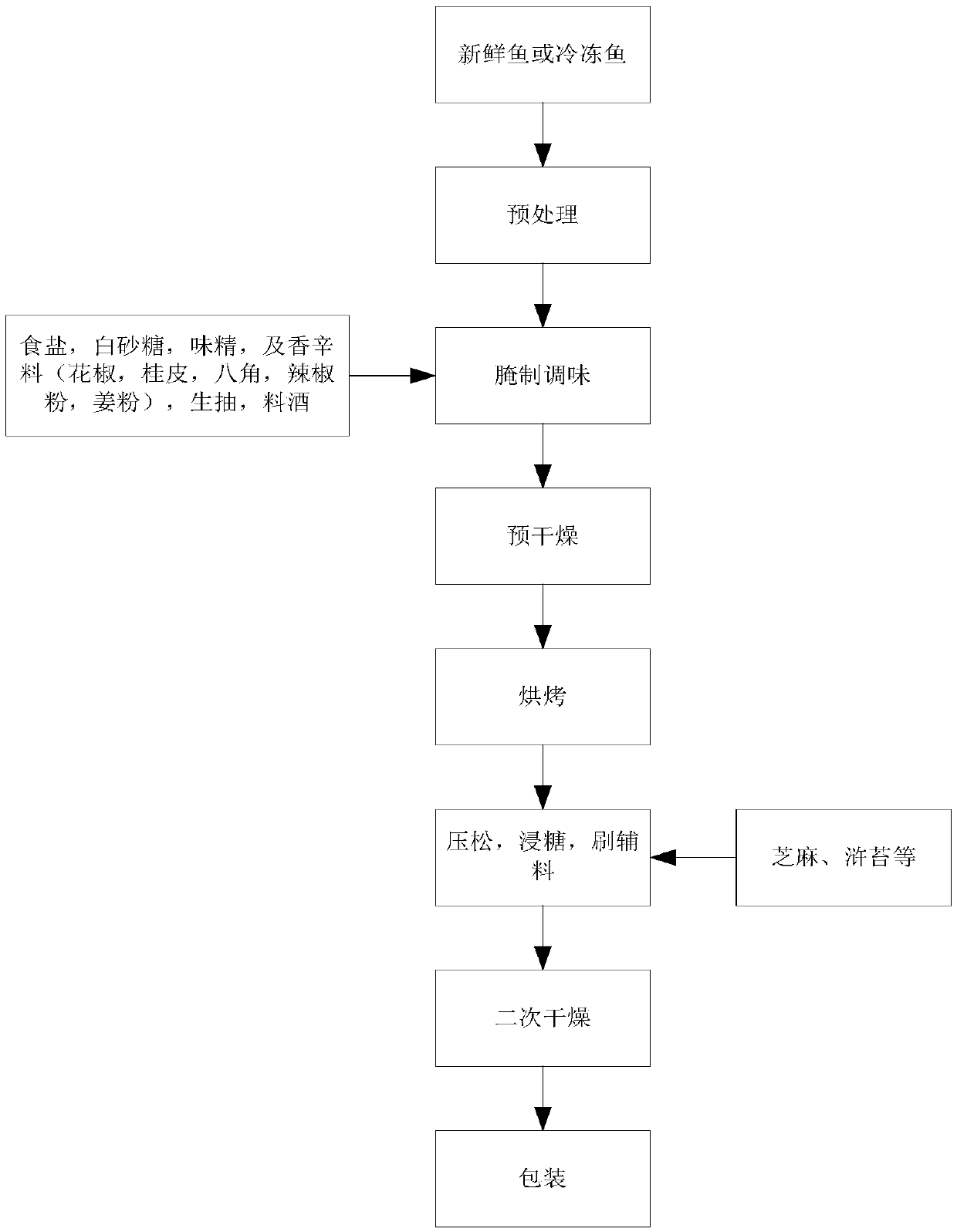

A processing method and crisp technology, applied in the fields of food preparation, food science, application, etc., can solve the problems of grilled fish products being too hard, not easy to tear and chew, restricting consumer groups, etc., to improve product quality, improve crispness, carry handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Take fresh or frozen plum fish with a body length of about 25cm and a mass of about 100g. After removing the scales, head and viscera, thoroughly wash and remove the blood stains and black film in the fish cavity, cut open along the back of the fish, and use an injection machine Needling for a more even marinade seasoning. Then put it in the seasoning liquid to marinate for 4 hours, the mass ratio of material to liquid is 1:2, and stir it every 30 minutes or so, so that the marinating seasoning can fully and evenly penetrate into the fish. The recipe for pickling seasoning liquid is: 5g of table salt, 1g of Chinese prickly ash, 1g of cinnamon, 1g of star anise, 1.5g of ginger powder, 3g of soy sauce, add 80g of water, cook for about 1 hour, then add 5g of white sugar, 1g of Monosodium glutamate, 0.5g of chili powder, 3g of cooking wine, continue to cook for about 10 minutes, cool, filter, add water to make up to 100g, and prepare a seasoning liquid. Drain the marinated...

Embodiment 2

[0028] Take fresh or frozen crucian carp, with a body length of about 20cm and a mass of about 80g. After removing the scales, head, and viscera, thoroughly clean the blood and black film in the fish cavity, cut it open along the back of the fish, and use an injection machine needle Spike for a more even marinade seasoning. Then put it in the seasoning liquid to marinate for 3.5 hours, the mass ratio of material to liquid is 1:1.7, and stir once every 27 minutes or so, so that the marinating seasoning can fully and evenly penetrate into the fish. The recipe for pickling seasoning liquid is: 4g of salt, 0.7g of pepper, 0.7g of cinnamon, 0.7g of star anise, 1.3g of ginger powder, 2.5g of soy sauce, add 80g of water, cook for about 1 hour, then add 4g of white Sugar, 0.7g of monosodium glutamate, 0.4g of chili powder, 2.5g of cooking wine, continue to cook for about 10 minutes, cool, filter, add water to 100g, and prepare a seasoning liquid. Drain the marinated and seasoned fish...

Embodiment 3

[0030]Take fresh or frozen crucian carp, with a body length of about 15cm and a mass of about 55g. After removing the scales, head, and viscera, thoroughly wash and remove the blood and black film in the fish cavity, cut open the fish along the back of the fish, and use an injection machine needle Spike for a more even marinade seasoning. Then put it in the seasoning liquid to marinate for 3 hours, the mass ratio of material to liquid is 1:1.5, and stir it every 30 minutes or so, so that the marinating seasoning can fully and evenly penetrate into the fish. The recipe for pickling seasoning liquid is: 3g of salt, 0.5g of pepper, 0.5g of cinnamon, 0.5g of star anise, 1g of ginger powder, 2g of soy sauce, add 80g of water, cook for about 1 hour, then add 3g of white sugar, 0.5g of monosodium glutamate, 0.3g of chili powder, 2g of cooking wine, continue to cook for about 10 minutes, cool, filter and add water to 100g to prepare a seasoning liquid. Drain the marinated and seasone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com