Perovskite based flexible film solar cell and preparation method thereof

A technology for solar cells and flexible films, applied in the field of solar cells, can solve the problems of difficulty in fully utilizing graphene, easy existence of energy barriers, poor graphene contact, etc., and achieves easy control of film thickness, simple and easy production process, and interface contact. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

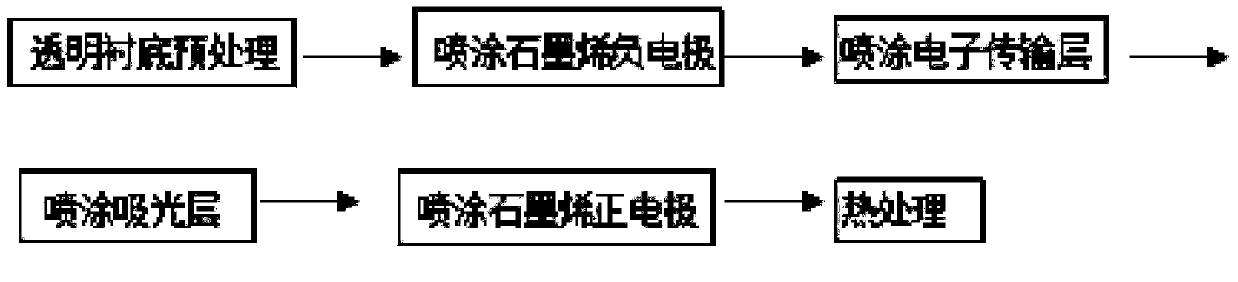

[0043] Such as figure 2 Shown, a kind of preparation method of perovskite-based flexible thin-film solar cell comprises the following steps:

[0044] (1) Transparent substrate pretreatment: select a polyethylene terephthalate transparent film with a thickness of 0.2-1.0 mm, wash it with ethanol to remove floating and sinking, and dry it at room temperature;

[0045] (2) Spraying graphene negative electrode: take 1g of single-layer graphene powder, ultrasonically disperse it in 20-1000ml ethanol solution, and prepare graphene / ethanol solution with graphene concentration of 0.001-0.050g / ml, in an electrostatic field of 10 Spray on the transparent substrate under the condition of ~50kV, and directly form a graphene negative electrode layer with a thickness of 50~200nm;

[0046] (3) Spray electron transport layer: Take 1g of single-layer graphene powder and 20g of titanium dioxide nanopowder with a particle size of 50-200nm, disperse in 20-1000ml ethanol solution, and spray on g...

Embodiment 1

[0051] The preparation method of the present embodiment comprises the following steps:

[0052] (1) Transparent substrate pretreatment: select a polyethylene terephthalate (PET) transparent film with a thickness of 0.6mm, wash with ethanol to remove floating and sinking, and dry at room temperature;

[0053] (2) spray graphene negative electrode layer: get single-layer graphene powder 1g, ultrasonically disperse in 200ml ethanol solution, prepare the graphene / ethanol solution that concentration is 0.005g / ml, spray under the condition that electrostatic field is 30kV on On a transparent substrate, a graphene negative electrode layer with a thickness of 100nm is directly formed;

[0054] (3) Spray electron transport layer: take 1g of single-layer graphene powder, 20g of titanium dioxide nanopowder with a particle size of 100nm, disperse in 200ml ethanol solution, spray on the graphene negative electrode under the condition of electrostatic field of 30kV, and directly form An el...

Embodiment 2

[0060] The only difference from Example 1 is that in steps (2)(3)(4)(5), the voltage of the electrostatic field is 10kV. Other content is identical with embodiment 1.

[0061] The energy conversion efficiency of the perovskite-based flexible thin-film solar cell of this embodiment is 22%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electron mobility | aaaaa | aaaaa |

| energy conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com