A small bending radius impact-resistant lightweight optical fiber power cable and its process flow

A bending radius and power cable technology, applied in the direction of power cables, insulated cables, communication cables, etc., can solve the problems of increasing the outer diameter and weight of cables, insulation extrusion damage, and increased difficulty, so as to improve safety and reliability, Effects of ensuring electrical safety performance and reducing outer diameter and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

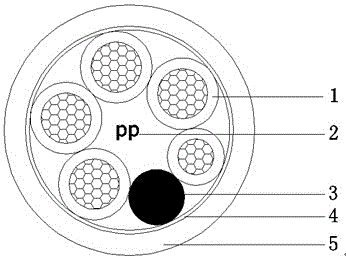

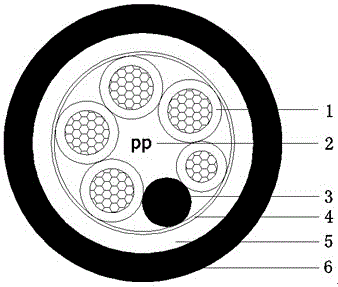

[0060] Such as figure 1 As shown, a small bending radius impact-resistant light optical fiber power cable includes a power transmission unit 1, a wrapping tape 4, an aluminum alloy tape interlocking armor 5 and an outer sheath 6, and a number of power transmission cables are arranged in the wrapping tape 4 Unit 1, aluminum alloy belt interlocking armor 5 and outer sheath 6 are sheathed in turn around the wrapping tape 4; the power transmission unit 1 is composed of copper conductor or aluminum alloy conductor and cross-linked polyethylene insulation: the aluminum alloy conductor adopts high conductivity High efficiency and high creep resistance single wire and through the roll forming process, the filling factor of the conductor has reached more than 93%, the outer diameter of the conductor is minimized, and the weight is reduced by 50% compared with the copper conductor with the same electrical performance; at the same time After heat treatment after molding, the bending radi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com