Constant-temperature control device and method for reaction liquid in cuvette of full-automatic biochemical analyzer

A biochemical analyzer, constant temperature control technology, applied in the direction of temperature control using electric mode, auxiliary controller with auxiliary heating device, analysis of materials, etc., can solve the problem of affecting the thermal balance of the cavity, nonlinear environmental temperature and Control accuracy errors and other issues, to avoid thermal inertia overshoot, improve sampling accuracy, and overcome inertial overshoot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

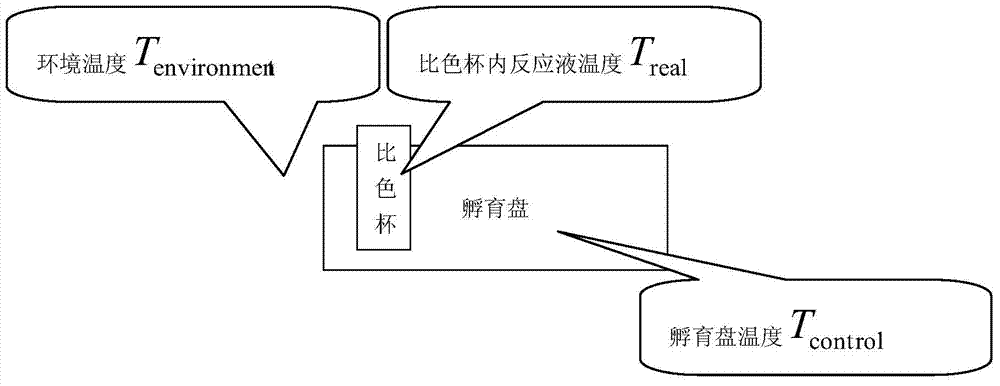

[0032] like figure 2 As shown, the reaction liquid constant temperature control device of the fully automatic photoelectric colorimetric analysis instrument provided by the present invention includes an incubation plate temperature sensor, and also includes a reaction liquid temperature sensor, an ambient temperature sensor, a single-chip microcomputer, a voltage-controlled drive circuit and a heater;

[0033] The reaction solution temperature sensor, the incubation plate temperature sensor, and the ambient temperature sensor are connected to the single-chip microcomputer;

[0034] The single chip microcomputer is connected with the voltage control drive circuit;

[0035] The voltage control driving circuit is connected with the heater;

[0036] The heater is connected with the incubation plate to heat the incubation plate.

[0037] Three or more different sensors ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com