Composite steel tube used for oil and gas conveying pipeline and externally wound by glass fiber resin reinforcing protective layer

A fiberglass resin and conveying pipeline technology, which is applied in pipeline protection, pipeline protection against damage/abrasion, pipes/pipe joints/fittings, etc., to achieve the effects of improving pressure bearing capacity, saving anti-corrosion costs, and reducing manufacturing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

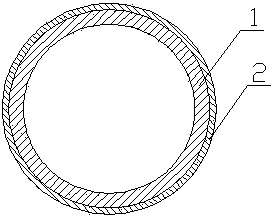

[0017] Such as figure 1 As shown, the composite pipe of this embodiment includes a pipeline steel base pipe 1 and a high-strength glass fiber reinforced resin layer 2. The glass fiber reinforced resin layer is a high-strength glass fiber or cloth tape impregnated with resin that is wound on the outer surface of the pipeline steel base pipe to form a new type of composite pipe for the construction of long-distance oil and gas pipelines with pipeline steel in the inner layer and FRP outer layer .

[0018] The base pipe 1 of this embodiment is a straight seam steel pipe, or a spiral steel pipe, which is welded by a submerged arc process. The outer diameter of the steel pipe is 1219mm, the wall thickness is 22mm, and the material is X80 pipeline steel. The high-strength glass fiber-reinforced resin layer 2 is composed of high-strength E glass fiber-reinforced resin, wound on the steel pipe base pipe, and the thickness of the glass fiber-reinforced resin layer after winding and curi...

Embodiment 2

[0022] The composite pipe of this embodiment is composed of a pipeline steel base pipe 1 and a fiberglass outer coating 2.

[0023] The base pipe of this embodiment is a longitudinal submerged arc welded steel pipe, the outer diameter of the steel pipe is 1422mm, the wall thickness is 21mm, and the material is X80 pipeline steel. The outer layer is composed of high-strength E glass fiber reinforced resin, wound on the steel pipe base pipe, and the thickness of the glass fiber reinforced resin composite layer after winding and curing is 5mm.

[0024] The composite pipe of this structure has the same pressure bearing capacity and reduced pipe weight compared with 100% pipeline steel pipe of the same wall thickness (outer diameter of 1422mm, wall thickness of 30.7 mm, material of X80 pipeline steel, 3PE external corrosion protection) 25%, reducing manufacturing costs by at least 20%.

[0025]

Embodiment 3

[0027] The composite pipe of this embodiment is composed of a pipeline steel base pipe 1 and a fiberglass outer coating 2.

[0028] The inner pipe of this embodiment adopts spiral submerged arc welded steel pipe, the outer diameter of the steel pipe is 508mm, the wall thickness is 9.5mm, and the material is X60 pipeline steel. The outer layer is composed of high-strength E glass fiber reinforced resin, which is wound on the steel pipe base pipe under appropriate tension. The thickness of the glass fiber reinforced resin composite layer after winding and curing is 3.2mm.

[0029] Compared with the 100% pipeline steel pipe of the same wall thickness (outer diameter of 508mm, wall thickness of 12.7mm, material of X60 pipeline steel, 3PE external anticorrosion), the composite pipe of this structure has a pressure bearing capacity increased by 38%. The weight of the pipe is reduced by 12%, and the manufacturing cost is reduced by at least 10%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com