An oxide nanoparticle doped wo 3 Gas sensitive coating and its preparation method

A technology of nano-particles and oxides, which is applied in coatings, metal material coating processes, fusion spraying, etc., can solve the problems of less gas-sensitive coating preparation, overcome difficulties in direct spraying, improve sensitivity, and process The effect of less process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

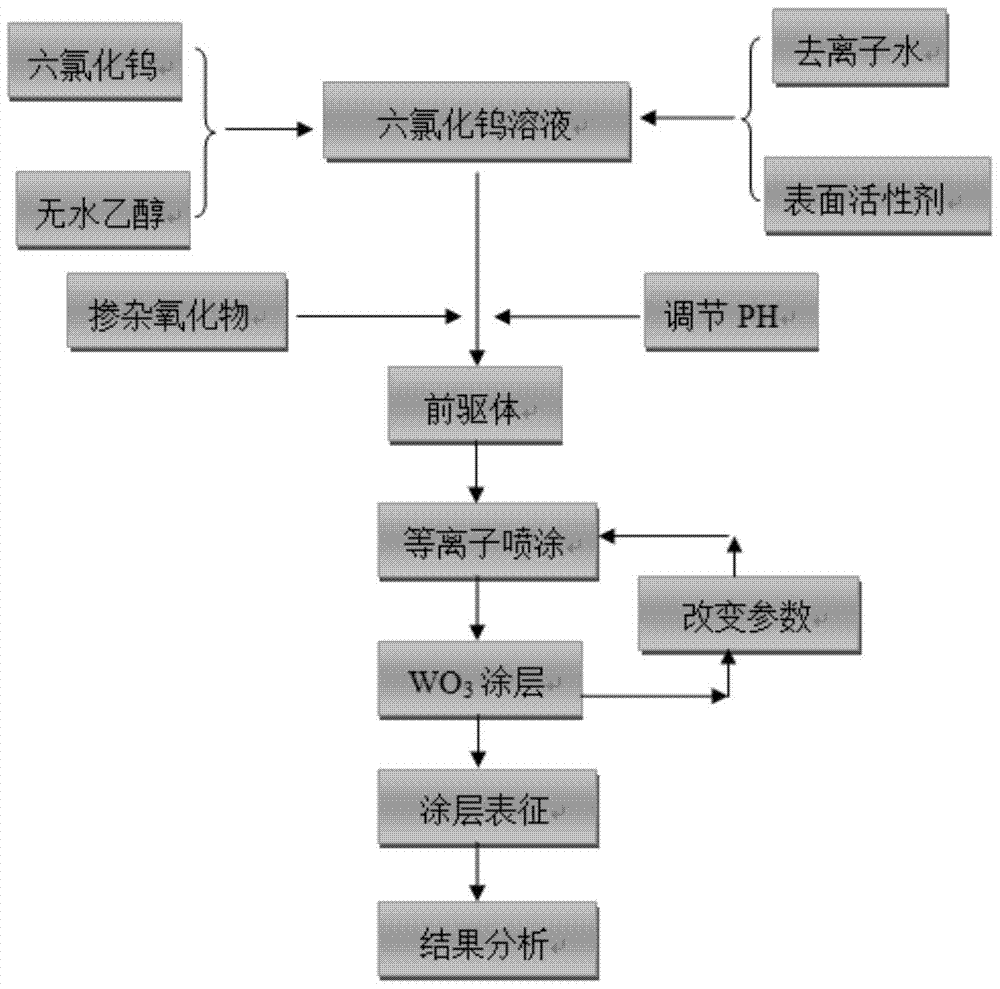

Embodiment 1

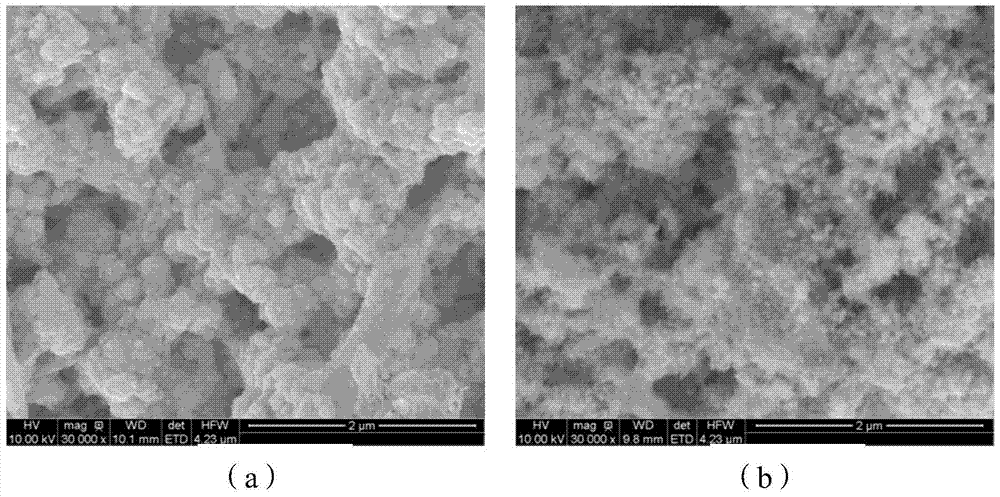

[0035] In this embodiment, the selected substrate material is a glass sheet with a thickness of about 1 mm, and the nanometer Al on the substrate is 2 o 3 Particle doped WCl 6 The thickness of the coating prepared by liquid material is about 500nm, in which Al 2 o 3 with WCl 6 The mass ratio is 1:20, the coating is WO 3 A porous surface made of stacked crystal grains, where WO 3 The grain size ranges from 10 to 50 nm. The porous submicron structure of Al 2 o 3 doped WO 3 The coating preparation process is as follows figure 1 As shown, the specific preparation method is as follows:

[0036] 1. First, commercially available WCl 6 Add it into absolute ethanol and stir evenly, ultrasonically disperse for 60min, at the same time add 0.06wt% surfactant polyethylene glycol (PEG600) into deionized water, stir it evenly, add it to WCl 6 in anhydrous ethanol solution, and ultrasonically dispersed for 40min to obtain WCl 6 A solution with a solid content of 4%, wherein deion...

Embodiment 2

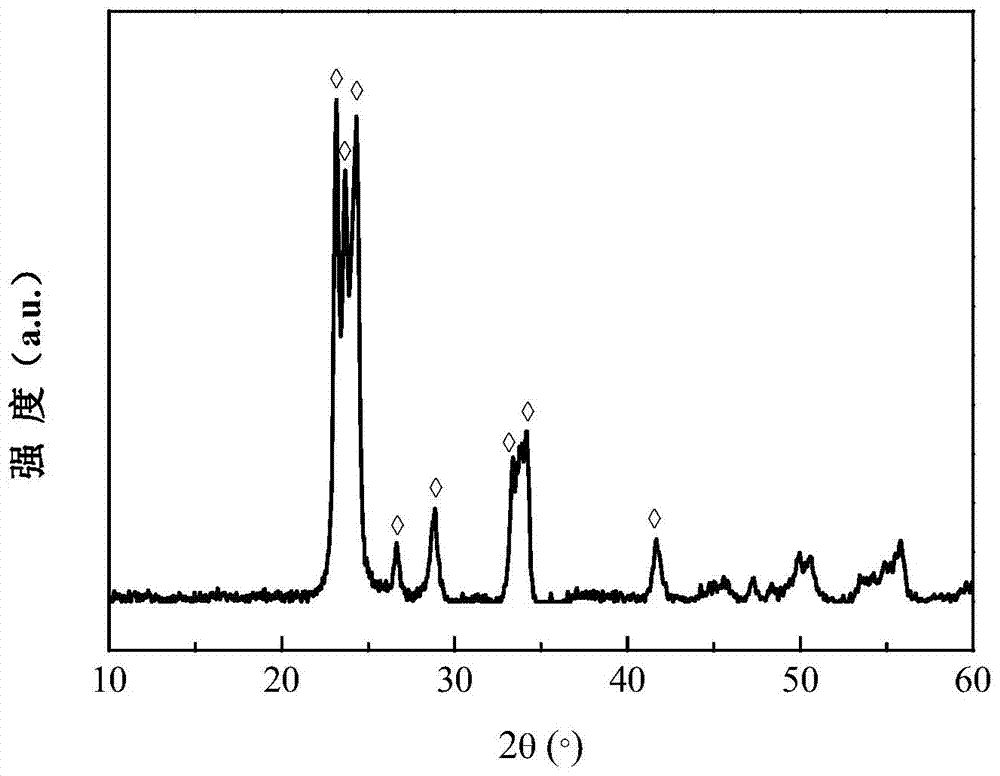

[0044] In this embodiment, the substrate is Al with a thickness of about 1mm 2 o 3 sheet, the substrate surface WO 3 The thickness of the coating is about 600nm, and the coating is well combined with the substrate; the surface of the coating is made of WO 3 The crystal grains are piled up, and the grain size ranges from 10 to 30 nm. The porous submicron size WO 3 The specific preparation method of the coating is as follows:

[0045] 1. First, commercially available WCl 6 Add it into absolute ethanol and stir evenly, ultrasonically disperse for 30min, and at the same time add 0.06wt% surfactant polyethylene glycol 20000 into deionized water, stir it evenly and add it to WCl 6 in anhydrous ethanol solution, and ultrasonically dispersed for 30 minutes to obtain WCl 6 A solution with a solid content of 4%, wherein deionized water and absolute ethanol are in a volume ratio of 1:1, and then the pH of the above solution is adjusted to 7 with ammonia under the condition of magne...

Embodiment 3

[0054] In this embodiment, the substrate is a glass slide with a thickness of about 1mm, and the surface of the substrate is WO 3 The thickness of the coating is about 500nm, and the coating is well combined with the substrate; the surface of the coating is made of WO 3 The crystal grains are piled up, and the grain size ranges from 10 to 40 nm. The WO of the porous submicron structure 3 The specific preparation method of the coating is as follows:

[0055] 1. First, commercially available WCl 6 Add it into absolute ethanol and stir evenly, ultrasonically disperse for 40min, and at the same time add 0.06wt% surfactant cetyltrimethylammonium bromide into deionized water, stir it evenly, add it to WCl 6 in anhydrous ethanol solution, and ultrasonically dispersed for 40min to obtain WCl 6 A solution with a solid content of 4%, wherein deionized water and absolute ethanol are in a volume ratio of 1:1, and then the pH of the above solution is adjusted to 7 with ammonia under th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com