Water dispersible profile control agent for oil extraction and preparation method thereof

A dispersive, profile-modifying agent technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve problems affecting the development effect of reservoir water flooding, unable to meet the needs of reservoir development, and intensified heterogeneity , to achieve the effects of reduced dosing time, good biological stability, and low initial viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

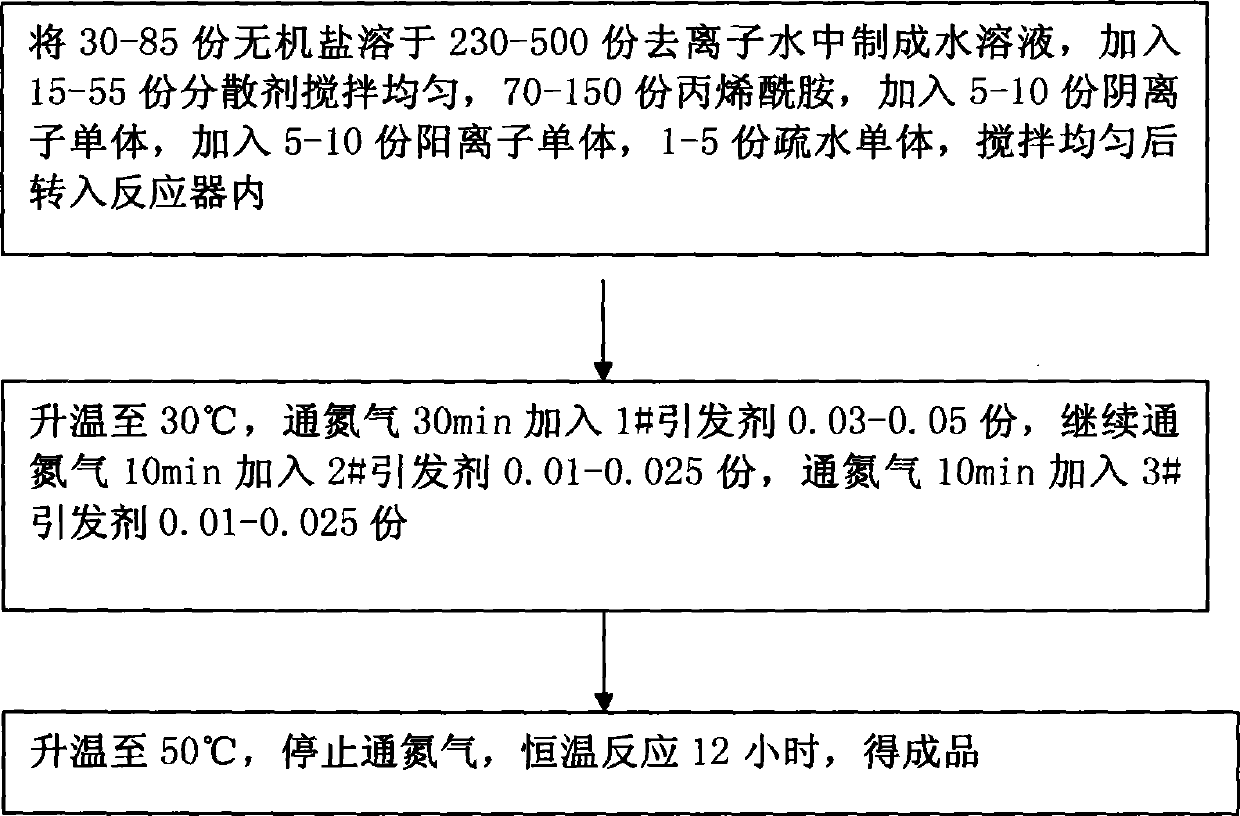

[0018] figure 1 It is a flow chart of a preparation method of a water-dispersed profile control agent for oil recovery.

[0019] A preparation method of a water-dispersed profile control agent for oil recovery, the method comprising the following steps:

[0020] Dissolve 30-85 parts of inorganic salt in 230-500 parts of deionized water to make an aqueous solution, add 15-55 parts of dispersant and stir evenly, add 70-150 parts of acrylamide, add 5-10 parts of anionic monomer, add 5-10 1 part of cationic monomer, 1-5 parts of hydrophobic monomer, stir evenly and transfer to the reactor, heat up to 30°C, add 0.03-0.05 parts of 1# initiator for 30 minutes with nitrogen gas, continue to flow nitrogen gas for 10 minutes, add 0.01 part of 2# initiator -0.025 parts, add 0.01-0.025 parts of 3# initiator for 10 minutes with nitrogen gas, heat up to 50°C, stop nitrogen gas flow, and react at constant temperature for 12 hours to obtain the finished product.

Embodiment 1

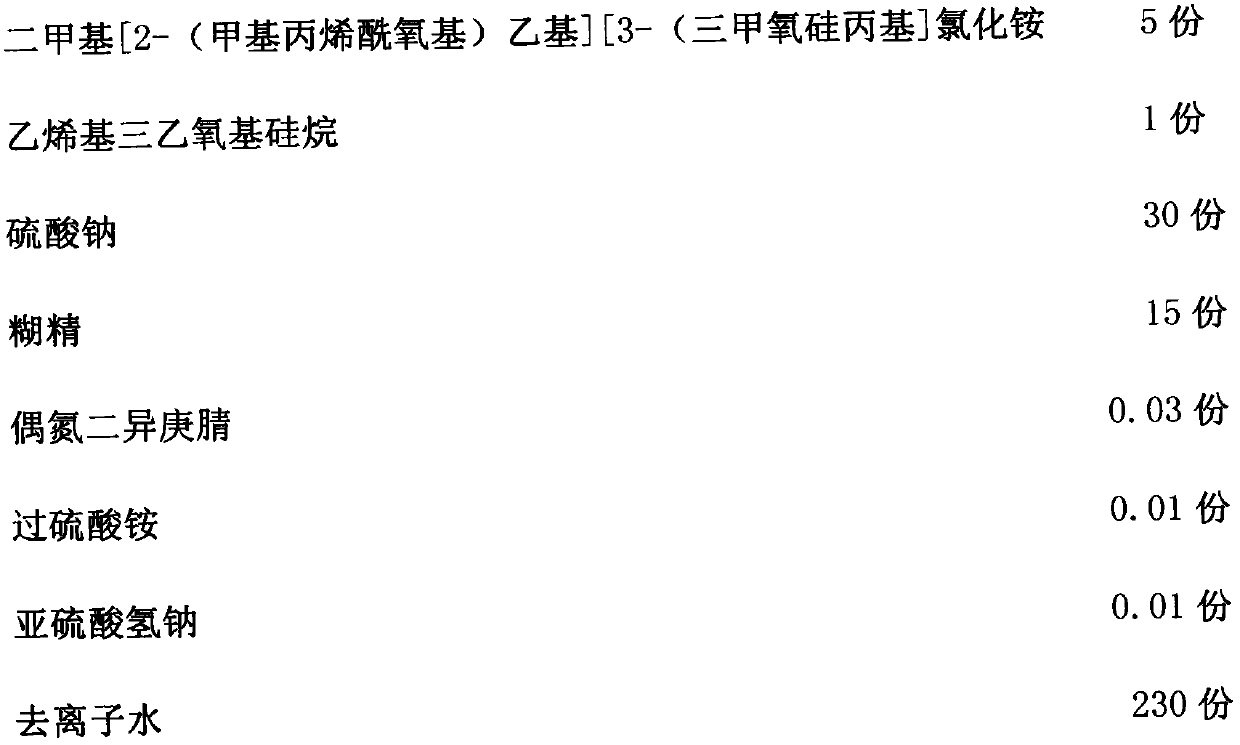

[0022] A preparation of a water-dispersed profile control agent for oil recovery, which consists of the following components:

[0023]

[0024]

[0025] Preparation Process:

[0026] Dissolve 30 parts of sodium sulfate in 230 parts of deionized water to make an aqueous solution, add 15 parts of dextrin and stir well, add 70 parts of acrylamide, add 5 parts of fluoromethacrylic acid, add 5 parts of dimethyl[2-(methyl Acryloyloxy)ethyl][3-(trimethoxysilylpropyl]ammonium chloride, 1 part of vinyltriethoxysilane, stir evenly, transfer to the reactor, heat up to 30°C, blow nitrogen for 30min and add 0.03 part of azobisisobutyronitrile, continue to pass nitrogen gas for 10 minutes, add 0.01 part of ammonium persulfate, add nitrogen gas for 10 minutes, add 0.01 part of sodium bisulfite, raise the temperature to 50°C, stop nitrogen gas flow, and react at constant temperature for 12 hours to obtain the finished product.

Embodiment 2

[0028] A preparation of a water-dispersed profile control agent for oil recovery, which consists of the following components:

[0029]

[0030]

[0031] Preparation Process:

[0032] Dissolve 85 parts of ammonium sulfate in 500 parts of deionized water to make an aqueous solution, add 55 parts of β-cyclodextrin and stir evenly, add 150 parts of acrylamide, add 10 parts of silicon-containing methacrylic acid, add 10 parts of 2-(methacrylic acid Acyloxy)ethyltrimethylammonium chloride, 5 parts of vinyltrimethoxysilane, stirred evenly, transferred to the reactor, raised the temperature to 30°C, passed nitrogen gas for 30 minutes, added 0.05 parts of azobisisoheptanonitrile, and continued to pass Add 0.025 parts of potassium persulfate under nitrogen for 10 minutes, add 0.025 parts of sodium thiosulfate for 10 minutes under nitrogen, raise the temperature to 50°C, stop nitrogen, and react at constant temperature for 12 hours to obtain the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com