A kind of preparation method of high-purity solid hydroxylamine sulfate

A high-purity technology of hydroxylamine sulfate, which is applied in the field of preparation of high-purity solid hydroxylamine sulfate, can solve the problems of low product yield of nitromethane route, complex process of acetone oxime route, restricting the competitiveness of hydroxylamine sulfate products, etc., and achieve reduction Decomposing risks, optimizing vacuum drying conditions, and improving the effect of recycling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

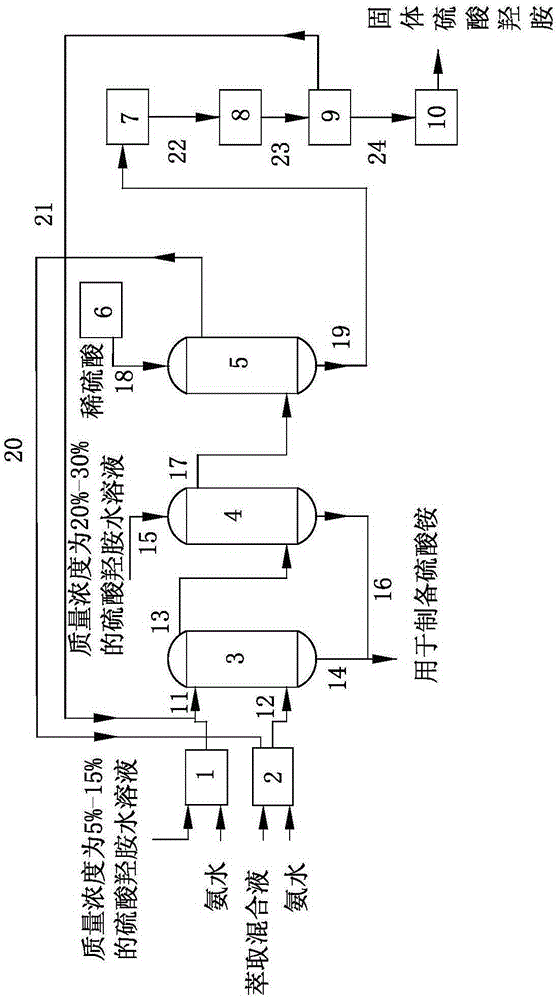

[0039] Control the temperature of the first reactor to be 23.9°C, add a hydroxylamine sulfate aqueous solution with a mass percentage concentration of 15% to the first reactor 1, slowly add ammonia water with a mass percentage concentration of 18.8% therein, stir and mix, and the stirring speed is 110rpm, Adjust the pH value of the solution to 5.9 and set aside. The extraction agent dioctyl phosphate, the diluent sulfonated kerosene, and the stabilizer dimethyl phosphite are fully mixed according to the volume ratio of 1:3:0.001 to obtain the extraction mixture, which is set aside; the temperature of the second reactor is controlled at 24.8°C, and the Add the above-mentioned mixed extraction mixture into the second reactor 2, slowly add ammonia water with a mass percentage concentration of 18.8% to it, the stirring speed is 110rpm, adjust the pH value of the solution to 7.1, the first reactor 1, the second reactor 2 reaction products enter the first extraction tower 3 simultan...

Embodiment 2

[0041] Control the temperature of the first reactor to be 25.4°C, add a hydroxylamine sulfate aqueous solution with a mass percentage concentration of 13.9% to the first reactor 1, slowly add ammonia water with a mass percentage concentration of 19.4% therein, stir and mix, and the stirring speed is 110rpm, Adjust the pH value of the solution to 6.0 and set aside. The extraction agent dioctyl phosphate, the diluent sulfonated kerosene, and the stabilizer dimethyl phosphite are fully mixed according to the volume ratio of 1:3.1:0.001 to obtain the extraction mixture, which is set aside; the temperature of the second reactor is controlled at 25.2°C, and the Add the above-mentioned mixed extraction mixture into the second reactor 2, slowly add ammonia water with a mass percentage concentration of 18.8% to it, the stirring speed is 110rpm, adjust the pH value of the solution to 7.1, the first reactor 1, the second reactor 2 reaction products enter the first extraction tower 3 simu...

Embodiment 3

[0043] Control the temperature of the first reactor to be 26.2°C, add a hydroxylamine sulfate aqueous solution with a mass percentage concentration of 12.1% to the first reactor 1, slowly add ammonia water with a mass percentage concentration of 20.7% therein, stir and mix, and the stirring speed is 110rpm, Adjust the pH of the solution to 6.1. The extractant dioctyl phosphate, the diluent sulfonated kerosene, and the stabilizer dimethyl phosphite are fully mixed according to the volume ratio of 1:3.2:0.0015 to obtain the extraction mixture, which is set aside; the temperature of the second reactor is controlled at 25.6°C, and the second Add the above-mentioned mixed extraction mixture into the reactor 2, slowly add ammonia water with a mass percentage concentration of 18.4% to it, the stirring speed is 110rpm, adjust the pH value of the solution to 7.3, the first reactor 1, the second reactor 2 Reaction product enters the first extraction tower 3 simultaneously according to v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com