Making method for high-tap-density surface-modified silver powder

A technology of tap density and surface modification, applied in the field of preparation of high tap density surface-modified silver powder, can solve the problems of low tap density and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

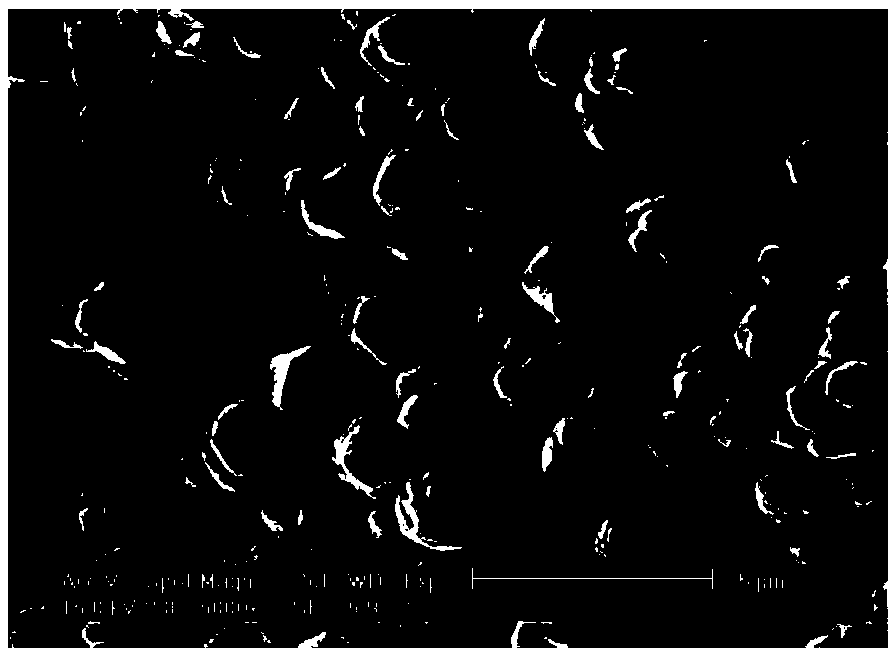

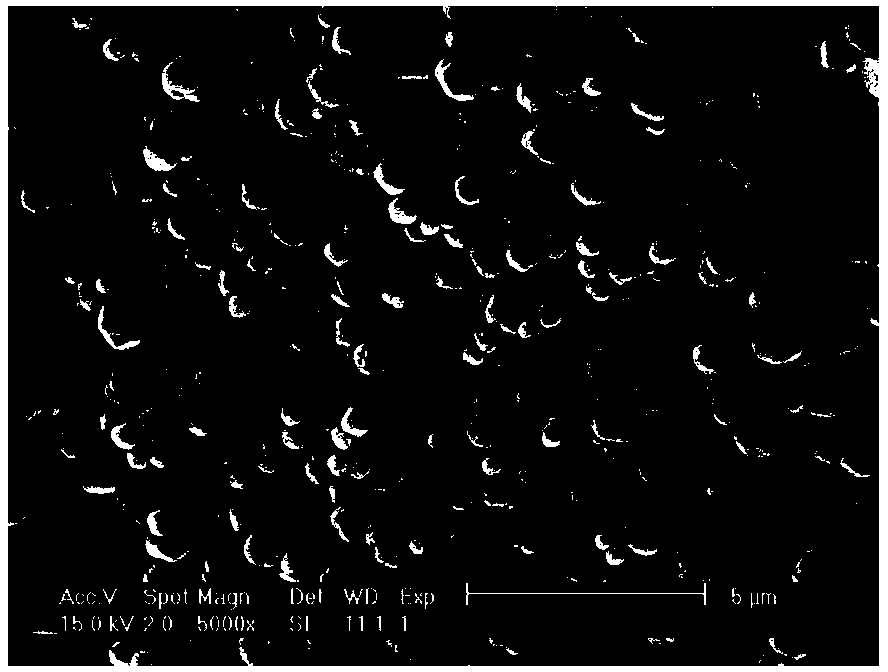

Image

Examples

preparation example Construction

[0033] The preparation method of the high tap density surface-modified silver powder of one embodiment, comprises the following steps:

[0034] Step S1, preparing silver powder.

[0035] Silver powder can be prepared by methods commonly used in the industry, such as gas phase method, solid phase method and liquid phase method. Preferably, it is prepared by a liquid phase method.

[0036] Preferably, the silver powder is spherical silver. More preferably, the specific surface area of spherical silver is 0.3-0.8m 2 / g.

[0037] In one of the embodiments, the silver powder is prepared by the following steps:

[0038] Step 111, dissolving silver nitrate and surfactant in water to prepare a silver solution, the concentration of silver ions in the silver solution is 50g / L-250g / L.

[0039] Preferably, the surfactant is at least one of gelatin, polyvinyl alcohol, hydroxyethyl cellulose, pectin and polyvinylpyrrolidone.

[0040] Preferably, the mass ratio of silver nitrate to s...

Embodiment 1

[0079] Dissolve 157g silver nitrate and 15g gelatin in 1L deionized water (hereinafter referred to as water), stir and dissolve to obtain a silver solution; dissolve 110g ascorbic acid and 15g gelatin in 1L water, add 5wt% nitric acid solution to adjust the pH value to 2, and obtain Stock solution, control the reaction temperature at (30-35°C), use 5wt% sodium carbonate solution to control the pH value of the reducing solution between 2 and 3, add the silver solution dropwise to the reducing solution within 10 minutes, and stir after adding After 15 minutes, let it stand for precipitation, wash the silver powder with water until the conductivity is less than 50μs / cm, filter it and dry it at 60°C, and sieve it to get silver powder. Put 200 g of zirconium balls with a diameter of 1.5 mm and 0.2 g of oleic acid in a ball mill jar for ball milling for 30 min at a speed of 300 RPM. After the ball milling, put 100g of the above-mentioned silver powder into the ball milling jar, and ...

Embodiment 2

[0082] Dissolve 157g of silver nitrate and 10g of polyvinyl alcohol in 2L of water, stir and dissolve to obtain a silver solution; dissolve 110g of ascorbic acid and 10g of polyvinyl alcohol in 0.4L of water, add 5wt% ammonia solution to adjust the pH to 4, and obtain a reducing solution. Control the reaction temperature at (30-35°C), use 5wt% ammonia solution to control the pH value of the reduction solution between 4 and 5, add the silver solution dropwise to the reduction solution within 120 minutes, and stir for 15 minutes after the addition is complete. Let it stand for precipitation, wash the silver powder with water until the conductivity is less than 50μs / cm, filter and dry at 60°C, and sieve to obtain silver powder. 200 g of zirconium balls with a diameter of 1 mm and 0.1 g of ammonium stearate were placed in a ball mill jar for ball milling for 30 min at a speed of 300 RPM. After the ball milling, put 100g of silver powder into the ball milling pot, and continue the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com