A kind of water-based composite baking varnish for photo frame

A water-based, photo frame technology, applied in the field of baking paint, which can solve the problems of insufficient water resistance and adhesion, peeling or blistering, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

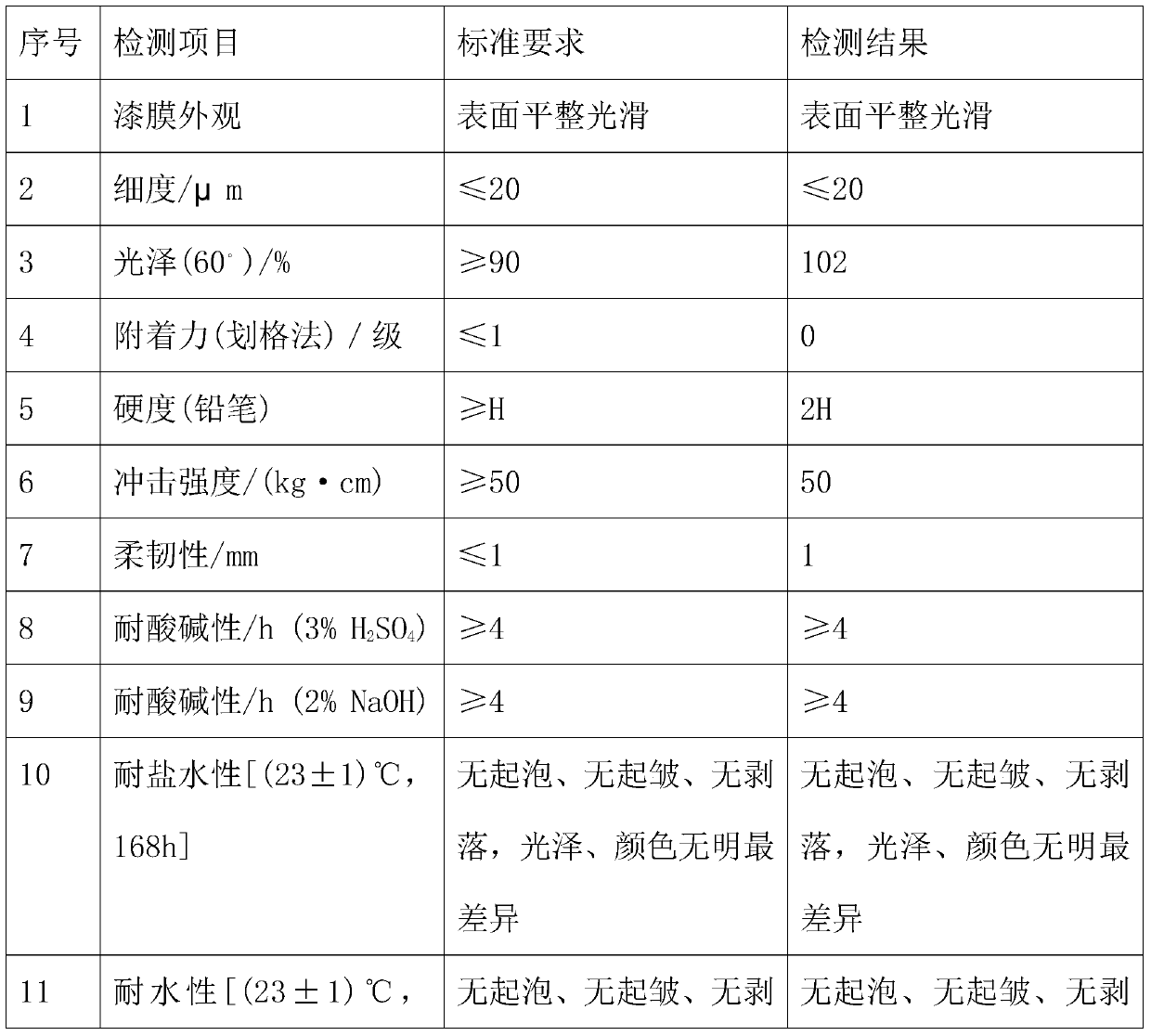

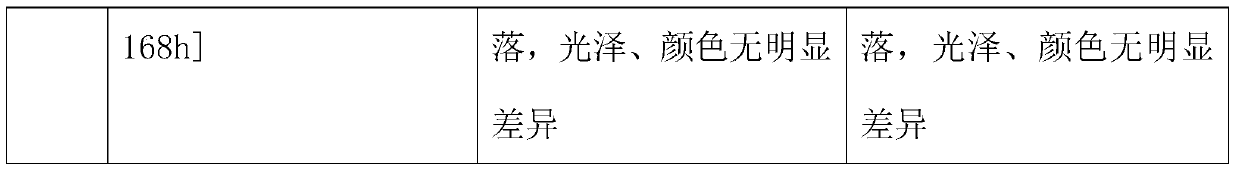

Examples

Embodiment 1

[0022] In this embodiment, a kind of water-based composite baking varnish for photo frame is composed of two components A and B with a mass ratio of 1:2; wherein,

[0023] The raw materials of component A include by weight: 55 parts of polyacrylic resin, 35 parts of polyhydroxy unsaturated polyester resin, 10 parts of polyacrylamide resin, 55 parts of titanium dioxide, 3 parts of adhesion promoter, ethylene glycol mono 8 parts of butyl ether, 1 part of nano-zinc carbonate, 1.5 parts of wetting agent, 0.5 parts of defoamer, 1 part of dispersant, 20 parts of deionized water;

[0024] The raw materials of component B include by weight: 15 parts of polyacrylic resin, 15 parts of curing agent, 0.5 parts of leveling agent, and 30 parts of deionized water;

[0025] The preparation method of the polyhydroxy unsaturated polyester resin comprises: carrying out a melt polycondensation reaction of dibasic acid and polyol with a molar ratio of 1:1 at 240° C., when the viscosity of the reac...

Embodiment 2

[0028] In the present embodiment, a kind of water-based composite baking varnish for photo frame is composed of two components A and B with a mass ratio of 1:3; wherein,

[0029] The raw materials of component A include by weight: 75 parts of polyacrylic resin, 15 parts of polyhydroxy unsaturated polyester resin, 20 parts of polyacrylamide resin, 35 parts of titanium dioxide, 10 parts of adhesion promoter, ethylene glycol mono 2 parts of butyl ether, 3 parts of nano-zinc carbonate, 0.5 parts of wetting agent, 1 part of defoamer, 0.5 parts of dispersant, 45 parts of deionized water;

[0030] The raw materials of component B include by weight: 25 parts of polyacrylic resin, 7 parts of curing agent, 1 part of leveling agent, and 10 parts of deionized water;

[0031] The preparation method of the polyhydroxy unsaturated polyester resin comprises: carrying out a melt polycondensation reaction of dibasic acid and polyhydric alcohol with a molar ratio of 1:1.8 at 210°C, when the visc...

Embodiment 3

[0034] In the present embodiment, a kind of water-based composite baking varnish for photo frame is composed of two components A and B with a mass ratio of 1:2.5; wherein,

[0035]The raw materials of component A include by weight: 60 parts of polyacrylic resin, 30 parts of polyhydroxy unsaturated polyester resin, 12 parts of polyacrylamide resin, 50 parts of titanium dioxide, 5 parts of adhesion promoter, ethylene glycol mono 6 parts of butyl ether, 1 part of nano zinc carbonate, 1.2 parts of wetting agent, 0.7 parts of defoamer, 0.8 parts of dispersant, 30 parts of deionized water;

[0036] The raw materials of component B include by weight: 18 parts of polyacrylic resin, 12 parts of curing agent, 0.7 parts of leveling agent, and 25 parts of deionized water;

[0037] The preparation method of the polyhydroxy unsaturated polyester resin comprises: carrying out a melt polycondensation reaction of dibasic acid and polyol with a molar ratio of 1:1.4 at 225°C, when the viscosity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com