A kind of cleaning equipment specially used for oil and gas pipeline 3pe anti-corrosion layer

A technology for cleaning equipment and oil and gas pipelines. It is applied in the directions of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc. It can solve problems such as affecting pipeline performance, complicated operation, and damage to pipelines, and achieves automatic operation. Wide-ranging, productivity-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in combination with specific embodiments.

[0015] A cleaning method dedicated to the 3PE anti-corrosion layer of oil and gas pipelines,

[0016] Including the following steps:

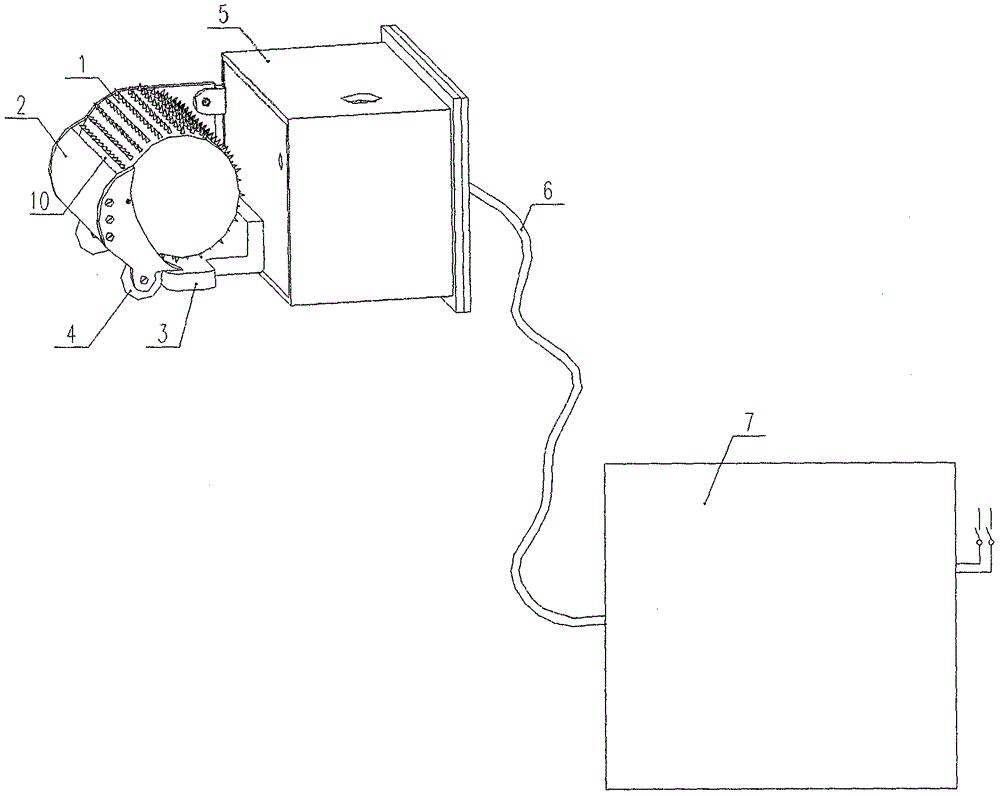

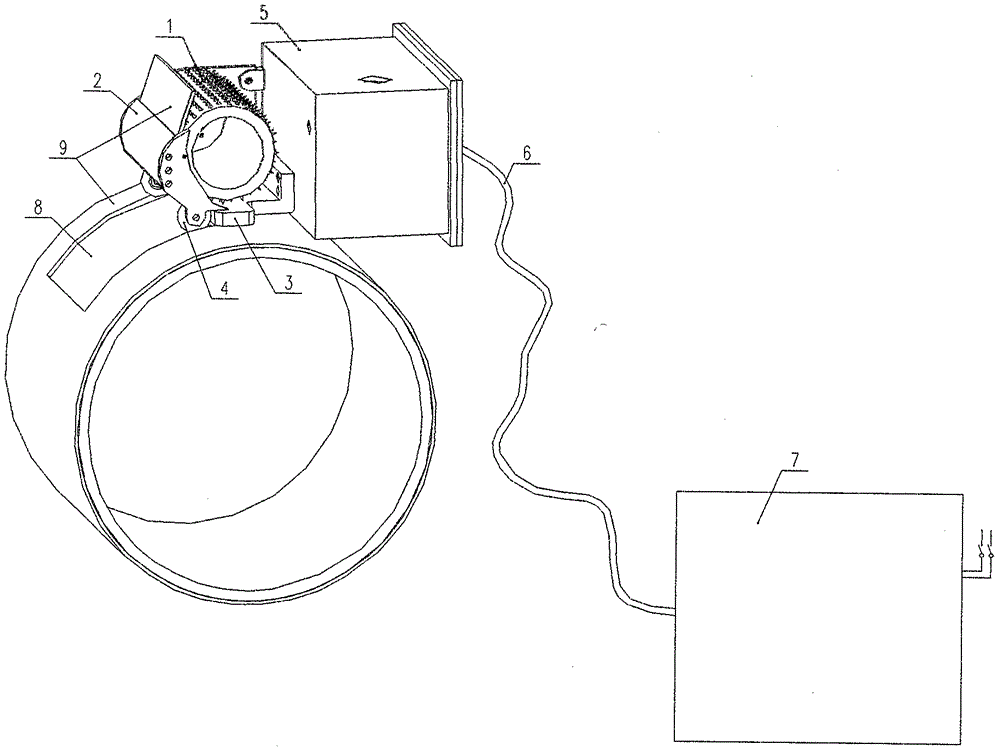

[0017] The first step is to break the opening of the polyethylene layer, then press it into the roller of the machine, turn the roller clockwise to automatically tighten, and the whole machine is close to the pipe wall.

[0018] The second step is to aim the electromagnetic wave generator at the area to be cleaned, and use waveguide technology to guide the electromagnetic wave to act on a specific area, and directly destroy the molecular structure of the adhesive layer through electromagnetic energy, making it harden and fail instantly at room temperature;

[0019] In the third step, the PE layer is separated from the epoxy layer under the action of mechanical force, and the polyethylene layer is separated from the pipe wall, and the roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com