Nickel-cobalt alloy/tetragonal polycrystalline zirconia composite ceramic material and preparation method thereof

A nickel-cobalt alloy and composite ceramic technology, which is applied in the field of nickel-cobalt alloy/tetragonal polycrystalline zirconia composite ceramic materials and its preparation, can solve the problems of hydrogen safety that cannot be ignored, are not suitable for mass production, and have high equipment costs. Achieve the effects of low equipment cost, safe preparation process, and optimized microstructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

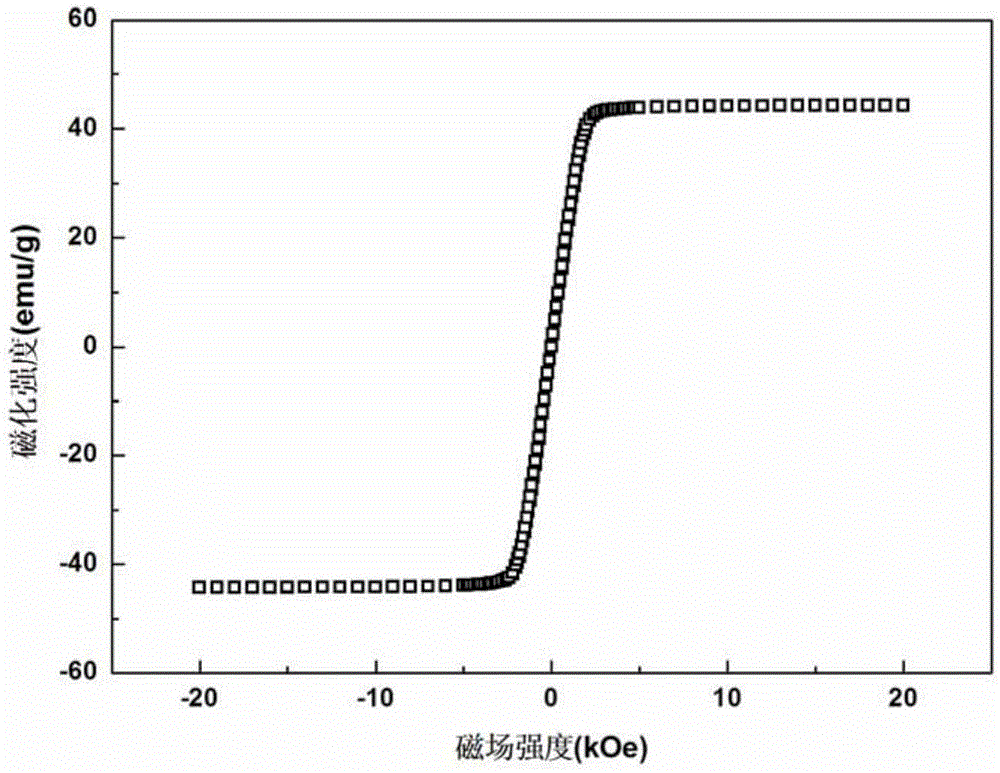

[0030]Take the nickel-cobalt alloy powder whose cobalt doping ratio after reduction is 0.25 (that is, x=0.25), add it to 3Y-TZP, the mass percentage content of nickel-cobalt alloy is 10% of 3Y-TZP, put the green body in Sintering at 1400°C for 2 hours under the protection of argon in a vacuum carbon tube furnace yields a high-density nickel-cobalt alloy / tetragonal polycrystalline zirconia composite ceramic. Its relative density reaches 96.5%, its flexural strength reaches 650MPa, and its fracture toughness reaches 5.5MPam. 1 / 2 , the saturation magnetic field strength of the alloy in the composite material is 80.9emu / g, and the coercive field is 4.3Oe. Comparing this example with Comparative Example 1, it can be seen that when the strontium doping amount is 0.25, the mechanical properties of the material are improved, the saturation magnetic field strength is increased, and the addition of cobalt to form an alloy not only improves the mechanical properties, but also improves th...

Embodiment 2

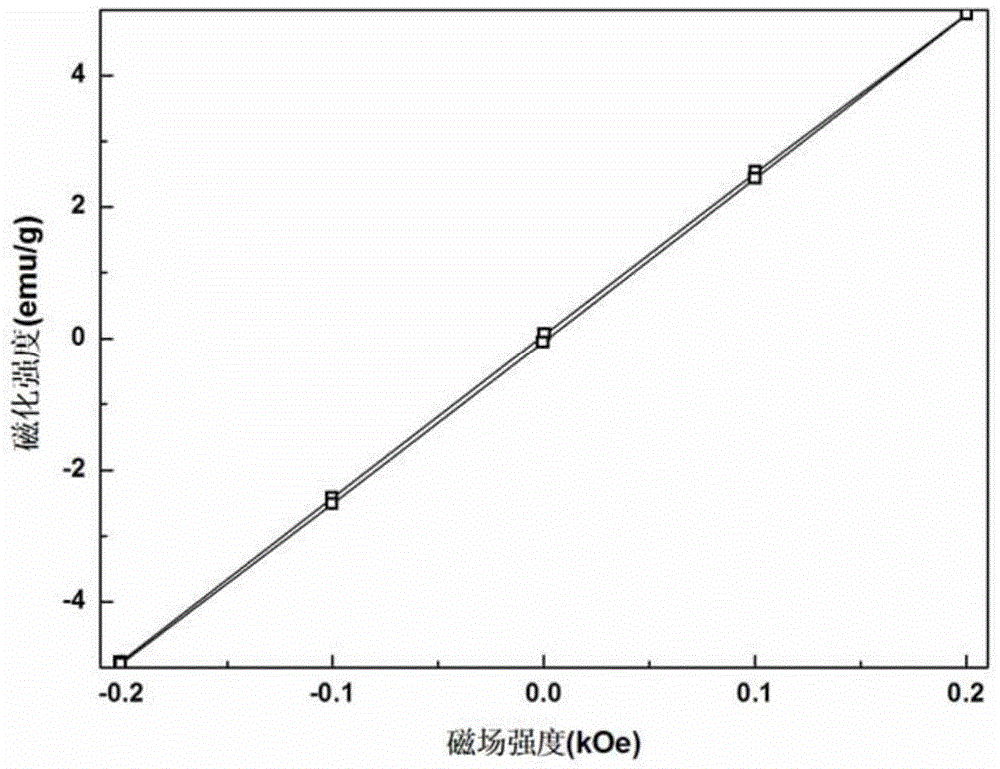

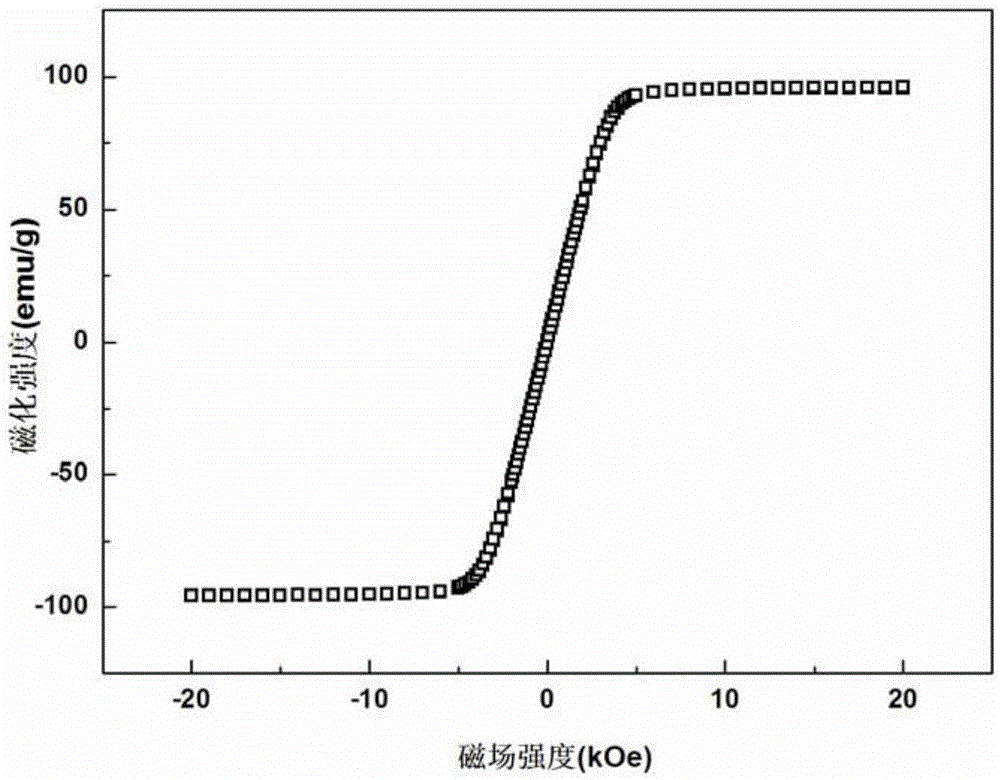

[0032] Take the nickel-cobalt alloy powder whose cobalt doping ratio after reduction is 0.5 (that is, x=0.5), add it to 3Y-TZP, the mass percentage content of nickel-cobalt alloy is 10% of 3Y-TZP, put the green body in Sintering at 1400°C for 2 hours under the protection of argon in a vacuum carbon tube furnace yields a high-density nickel-cobalt alloy / tetragonal polycrystalline zirconia composite ceramic. Its relative density reaches 97.9%, its flexural strength is 801MPa, and its fracture toughness is 5.7MPam. 1 / 2 ,according to image 3 and Figure 4 The hysteresis loop can be read out, the saturation magnetic field strength of the alloy in the composite material is 95.7emu / g, and the coercive field is 16.8Oe.

Embodiment 3

[0034] Take the nickel-cobalt alloy powder whose cobalt doping ratio after reduction is 0.75 (that is, x=0.75), add it to 3Y-TZP, the mass percentage content of nickel-cobalt alloy is 10% of 3Y-TZP, put the green body in Sintering at 1400°C for 2 hours under the protection of argon in a vacuum carbon tube furnace yields a high-density nickel-cobalt alloy / tetragonal polycrystalline zirconia composite ceramic. Its relative density reaches 96.9%, its flexural strength is 581MPa, and its fracture toughness is 5.3MPam 1 / 2 , the saturation magnetic field intensity of the alloy in the composite material reaches 95.7emu / g, and the coercive field is 12.9Oe. According to Example 2 and this example, it can be seen that too much cobalt doping will improve the magnetic properties, but it will also reduce the mechanical properties of the material, so cobalt can not be doped too much.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com