Self-hardening TiAlN/CrAlN multi-layer coated cutter and preparation method thereof

A multi-layer coating, self-hardening technology, applied in the direction of tools for lathes, turning equipment, layered products, etc., can solve the problem of thermal stability of the coating is not involved, and achieve excellent thermal stability, high temperature oxidation resistance The effect of age hardening and improvement of bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

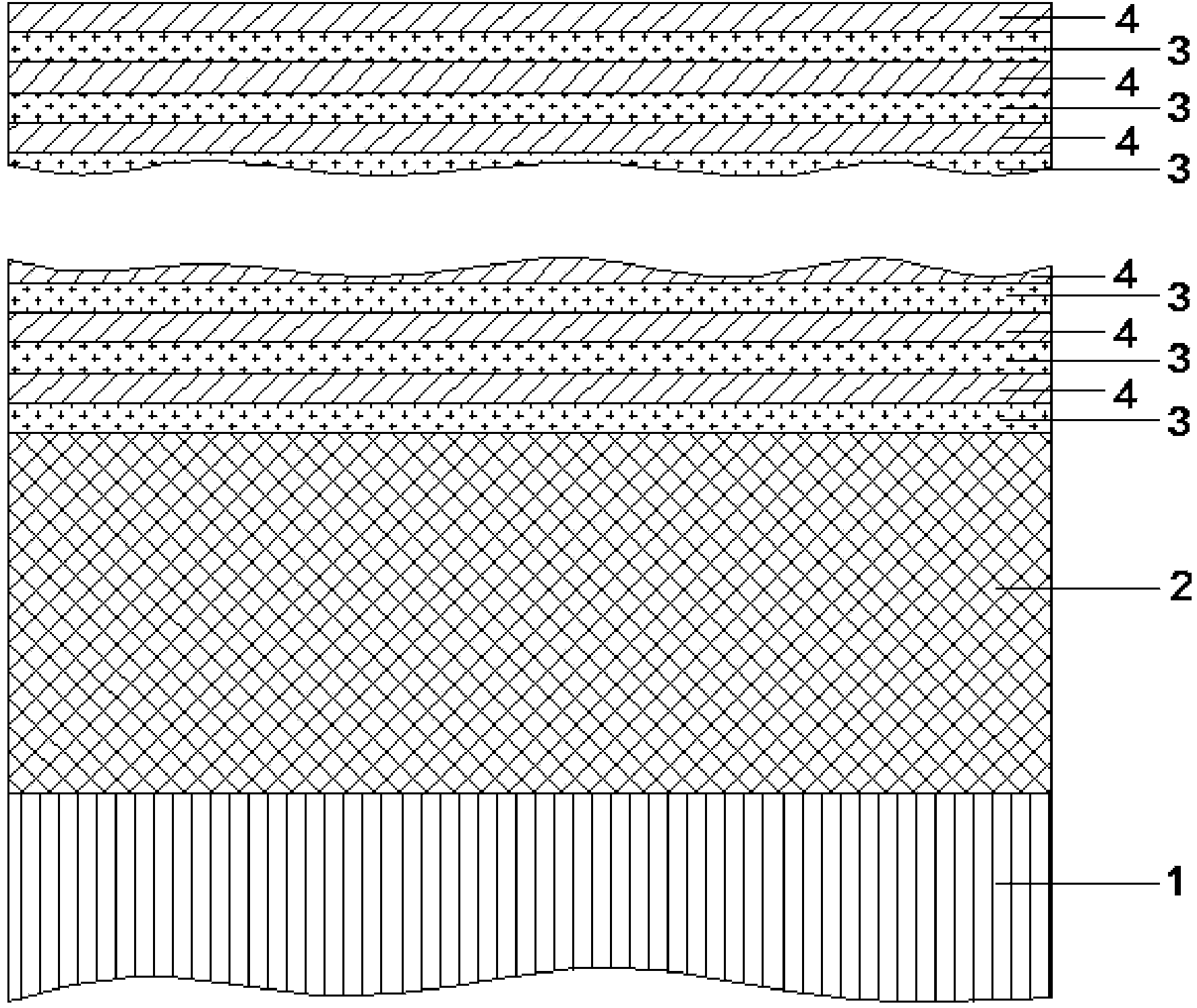

[0040] A self-hardening TiAlN / CrAlN multilayer coating tool of the present invention, such as figure 1 As shown, it includes a tool base 1 and a multi-layer coating deposited on the tool base 1, the multi-layer coating contains Ti 1-z al z N transition layer 2 and multi-cycle coating. Ti 1-z al z The N transition layer 2 is deposited on the surface of the tool substrate 1, and the multi-period coating is deposited on the Ti 1-z al z N transition layer 2. The multi-period coating is an alternate deposition of Ti 1-x al x N layer 3 and Cr 1-y al y The multilayer structure of N-layer 4, showing the 1-x al x N layer 3 to Cr 1-y al y N layer 4" is a multi-periodic change trend of a period. Ti 1-x al x The crystal structure of the N layer 3 is a face-centered cubic structure, Cr 1-y al y The crystal structure of the N layer 4 is a face-centered cubic structure, Ti 1-x al x N layer 3 and Cr 1-y al y N layer 4 co-epitaxy grown into a superlattice structure, Ti 1-...

Embodiment 2

[0044] A self-hardening TiAlN / CrAlN multilayer coating tool of the present invention, such as figure 1 As shown, it includes a tool base 1 and a multi-layer coating deposited on the tool base 1, the multi-layer coating contains Ti 1-z al z N transition layer 2 and multi-cycle coating. Ti 1-z al z The N transition layer 2 is deposited on the surface of the tool substrate 1, and the multi-period coating is deposited on the Ti 1-z al z N transition layer 2. Ti 1-z al z The N transition layer 2 is specifically Ti 0.50 al 0.50 The N transition layer has a thickness of 500nm. The multi-period coating is based on "Ti 1-x al x N layer 3 and Cr 1-y al y N layer 4" is the modulation cycle, specifically 200 cycles, where Ti 1-x al x N layer 3 is specifically Ti 0.50 al 0.50 N layer, thickness 10nm, Cr 1-y aly N layer 4 is specifically Cr 0.33 al 0.67 N layer with a thickness of 6nm. In this multi-layer coated tool, the total thickness of the multi-layer coating is 3...

Embodiment 3

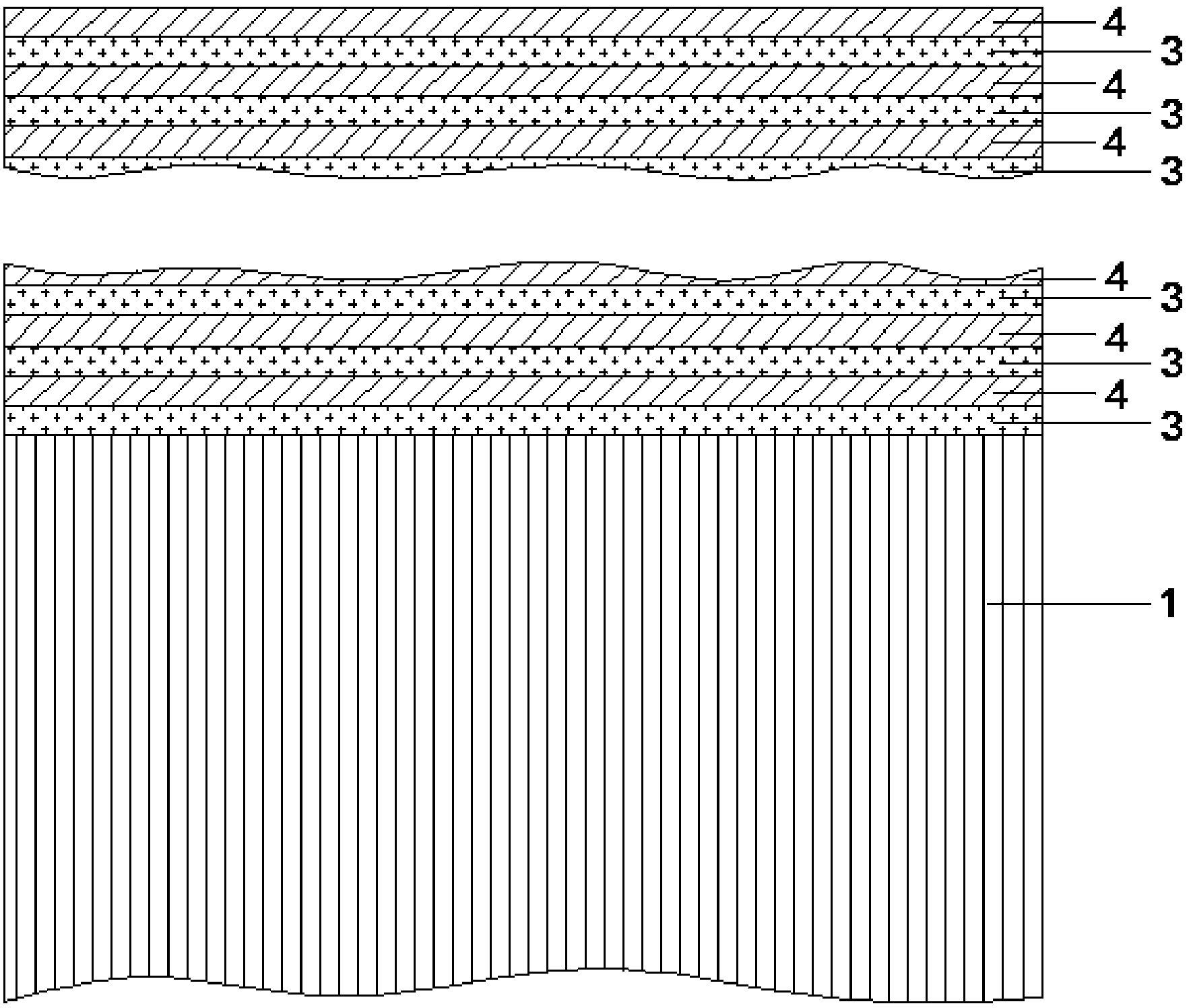

[0054] A self-hardening TiAlN / CrAlN multilayer coating tool of the present invention, such as figure 2 As shown, it includes a tool base 1 and a multi-layer coating deposited on the tool base 1, the multi-layer coating includes a multi-period coating. The multi-cycle coating is deposited on the tool substrate 1, based on the "Ti 1-x al x N layer 3 and Cr 1-y al y N layer 4" is the modulation cycle, specifically 200 cycles, where Ti 1-x al x N layer 3 is specifically Ti 0.50 al 0.50 N layer, thickness 10nm, Cr 1-y al y N layer 4 is specifically Cr 0.33 al 0.67 N layer with a thickness of 6nm. In this multilayer coated tool, the total thickness of the multilayer coating is 3.2 μm, and the total thickness of the multi-period coating is 3.2 μm.

[0055] In this embodiment, the multi-layer coating is based on the surface of the tool substrate to present "Ti 1-x al x N layer 3 to Cr 1-y al y Periodic variation trend of N-layer 4", Ti 1-x al x The crystal structure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com