Preparation method of nitrogen-doped graphene aerogel supported non-precious metal oxygen reduction catalyst

A technology of nitrogen-doped graphene and non-precious metals, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the low utilization rate of oxygen reduction active sites, unfavorable industrial production, and equipment requirements Advanced problems, easy to expand production, low production cost, simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

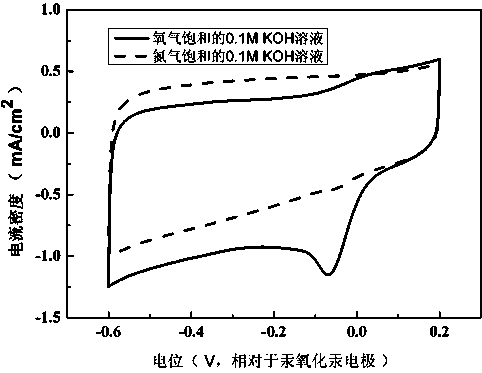

Embodiment 1

[0026] Weigh 0.62g melamine and disperse it in 20ml deionized water, add 1.2ml formaldehyde solution with a mass fraction of 37wt%, stir at 70°C for 0.5h to obtain a prepolymer, then add graphene oxide solution (100ml 1.0 mg / ml) and an aqueous solution containing 0.1g of ferrous sulfate, continuously stirred at 98°C for 3h to obtain a hydrogel, freeze-dried to obtain a nitrogen-doped graphene airgel loaded non-noble metal oxygen reduction catalyst precursor, and the above-mentioned nitrogen-doped graphene The airgel-loaded non-noble metal oxygen reduction catalyst precursor was placed in a porcelain boat, and under the protection of an inert gas, the temperature was raised to 800°C at a heating rate of 5°C / min and kept for 2 hours, and then naturally cooled to room temperature to obtain nitrogen-doped graphene gas condensation Gum-supported non-noble metal oxygen reduction catalysts.

[0027] Weigh 2.0 mg of the nitrogen-doped graphene airgel-supported non-noble metal oxygen r...

Embodiment 2

[0031] Weigh 0.4g of melamine and 0.4g of urea and disperse them in 20ml of deionized water, add 1.0ml of a glyoxal solution with a mass fraction of 40wt%, stir at 55°C for 2h to obtain a prepolymer, and then add a graphene oxide solution (50ml 1.0 mg / ml) and an aqueous solution containing 0.05 g cobalt sulfate, continuously stirred at 65 ° C for 24 h to obtain a hydrogel, freeze-dried to obtain a nitrogen-doped graphene airgel-loaded non-noble metal oxygen reduction catalyst precursor, the above nitrogen Doped graphene airgel loaded non-precious metal oxygen reduction catalyst precursor was placed in a ceramic boat, and under the protection of inert gas, the temperature was raised to 700°C at a heating rate of 1°C / min and kept for 1h, and then naturally cooled to room temperature to obtain nitrogen-doped Graphene airgel supported non-noble metal oxygen reduction catalyst.

Embodiment 3

[0033] Weigh 0.9g of dicyandiamide and disperse it in 20ml of deionized water, add 0.8ml of a glyoxal solution with a mass fraction of 40wt%, stir at 80°C for 0.5h to obtain a prepolymer, and then add a graphene oxide solution (200ml 1.0 mg / ml) and an aqueous solution containing 0.2g nickel nitrate, and continuously stirred at 85°C for 12h to obtain a hydrogel, which was supercritically dried with carbon dioxide to obtain a nitrogen-doped graphene airgel-loaded non-noble metal oxygen reduction catalyst precursor, which The above nitrogen-doped graphene airgel-loaded non-noble metal oxygen reduction catalyst precursor was placed in a porcelain boat, and under the protection of an inert gas, the temperature was raised to 1000°C at a heating rate of 10°C / min and kept for 4 hours, and naturally cooled to room temperature to obtain nitrogen Doped graphene airgel supported non-noble metal oxygen reduction catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com