High nitrogen doped graphene and fullerene-like molybdenum selenide hollow-ball nanocomposite and preparation method thereof

A technology of nanocomposite materials and nitrogen-doped graphene, applied in chemical instruments and methods, nanotechnology, nanotechnology, etc., can solve problems such as difficulties, few studies on heterogeneous atom doping, few studies, etc., and achieve simple operation , cheap experimental equipment, and controllable reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

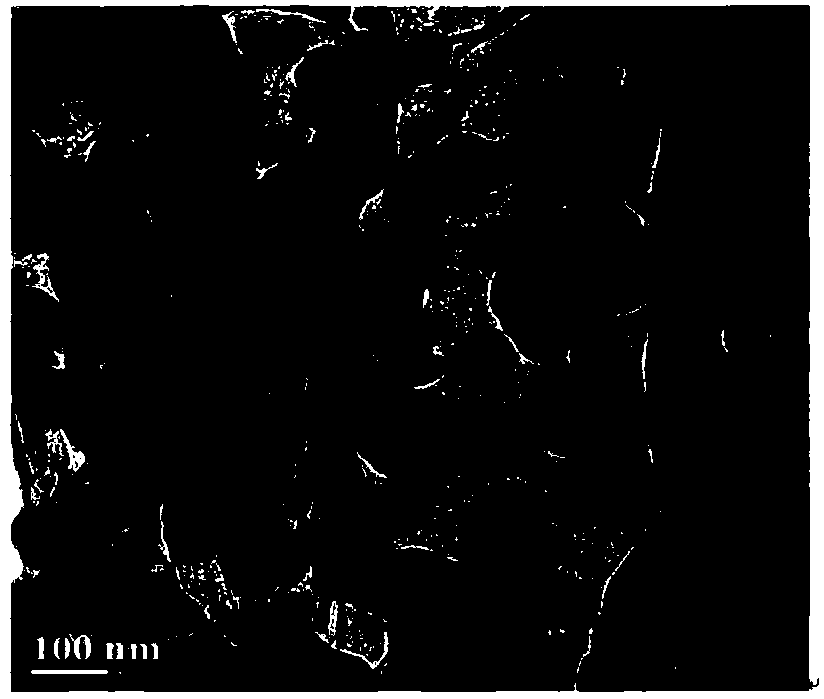

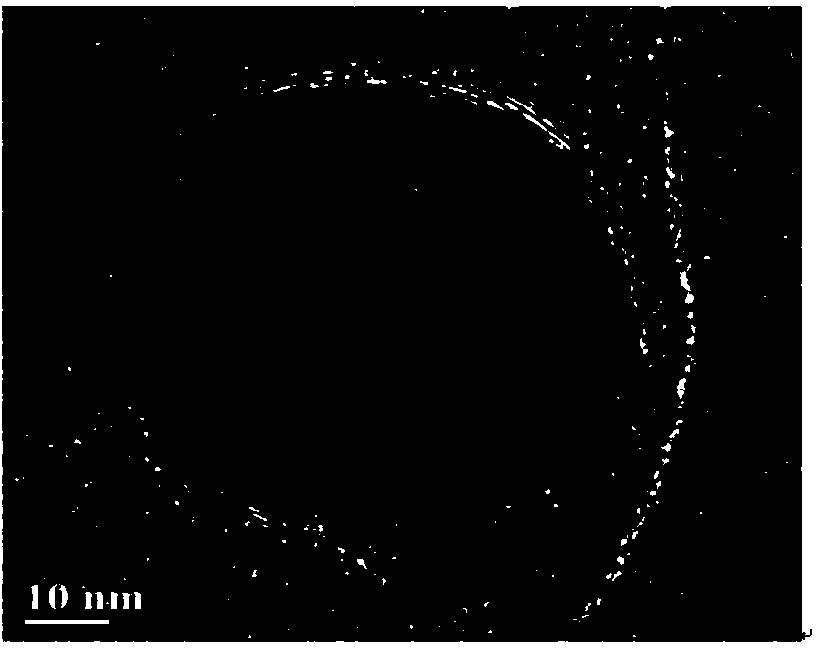

Image

Examples

Embodiment 1

[0031] 1) Preparation of low-nitrogen-doped graphene: Disperse 500 mg of graphene oxide (produced by the Hummers method) into 100 mL of aqueous solution, stir and sonicate to disperse evenly; then add 5 mL of NH to the dispersion 3 ·H 2 O (20%), stirring and heating to 90 ° C, through a chemical reaction for 2 hours, to obtain rough low-nitrogen graphene; finally, obtain high-quality low-nitrogen graphene through dialysis.

[0032] 2) Preparation of chemical reaction solution: 0.2 mmol of ammonium molybdate tetrahydrate, i.e. (NH 4 ) 6 Mo 7 o 24 4H 2 O and 3mmol of Na 2 SeO 3 dissolved in 15mL H 2 In the mixed solution that O and 15mL ethylene glycol form, stir 15 minutes;

[0033] Add 5 mL of diethylenetriamine (DETA) stabilizer to the above solution, stir for 15 minutes; get 5 low-nitrogen-doped graphene and add to the above solution, stir and sonicate for 30 minutes;

[0034] 3) Preparation of high-nitrogen-doped graphene and fullerene-like molybdenum selenide holl...

Embodiment 2

[0036] 1) Preparation of low-nitrogen-doped graphene: Disperse 500 mg of graphene oxide (produced by the Hummers method) into 100 mL of aqueous solution, stir and sonicate to disperse evenly; then add 10 mL of NH to the dispersion 3 ·H 2 O (20%), stirring and heating to 90 ° C, through a chemical reaction for 10 hours, to obtain rough low-nitrogen graphene; finally, obtain high-quality low-nitrogen graphene through dialysis.

[0037] 2) Preparation of chemical reaction solution: 0.5 mmol of ammonium molybdate tetrahydrate, i.e. (NH 4 ) 6 Mo 7 o 24 4H 2 O and 10mmol of Na 2 SeO 3 dissolved in 15mL H 2 In a mixed solution composed of O and 15mL ethylene glycol, stir for 15 minutes;

[0038] Add 15 mL of diethylenetriamine (DETA) stabilizer to the above solution, stir for 15 minutes; take 15 mL of low-nitrogen-doped graphene and add it to the above solution, stir and sonicate for 30 minutes;

[0039] 3) Preparation of high-nitrogen-doped graphene and fullerene-like molyb...

Embodiment 3

[0041] 1) Preparation of low-nitrogen-doped graphene: Disperse 500 mg of graphene oxide (produced by the Hummers method) into 100 mL of aqueous solution, stir and sonicate to disperse evenly; then add 15 mL of NH to the dispersion 3 ·H 2 O (20%), stirring and heating to 90 ° C, through a chemical reaction for 10 hours, to obtain rough low-nitrogen graphene; finally, obtain high-quality low-nitrogen graphene through dialysis.

[0042] 2) Preparation of chemical reaction solution: 1.5mmol of ammonium molybdate tetrahydrate, i.e. (NH 4 ) 6 Mo 7 o 24 4H 2 O and 15mmol of Na 2 SeO 3 dissolved in 15mL H 2 In a mixed solution composed of O and 15mL ethylene glycol, stir for 15 minutes;

[0043] Add 25mL of diethylenetriamine (DETA) stabilizer to the above solution, stir for 15 minutes; take 20mL of low-nitrogen-doped graphene and add to the above solution, stir and sonicate for 30 minutes;

[0044] 3) Preparation of high-nitrogen-doped graphene and fullerene-like molybdenum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com