Air electrode of lithium air battery, preparation method of air electrode and lithium air battery

A lithium-air battery and air electrode technology, which is applied in battery electrodes, fuel cell-type half-cells and secondary battery-type half-cells, circuits, etc., to achieve the effects of alleviating polarization phenomenon, simple operation, and suitable for mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

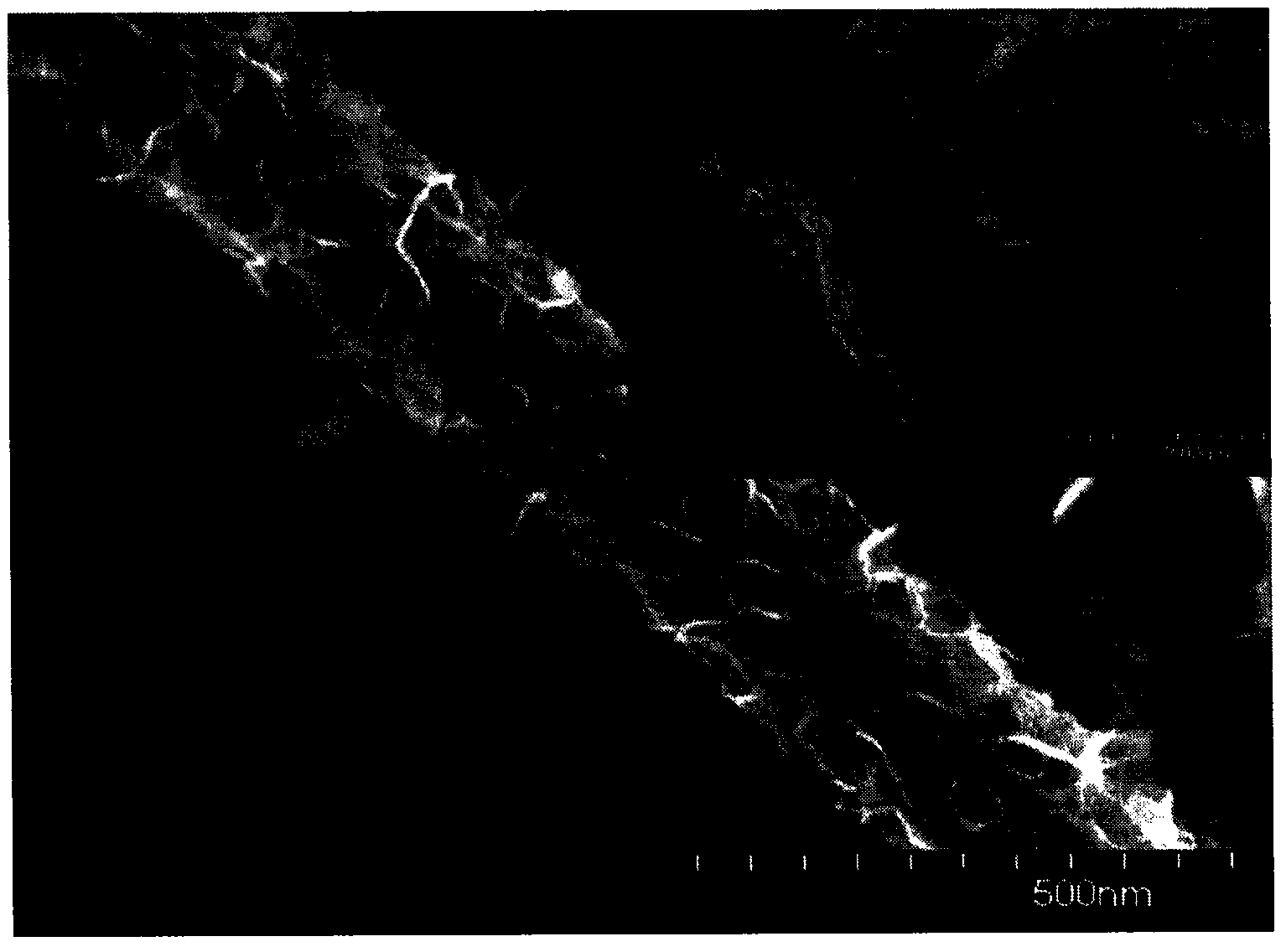

Image

Examples

Embodiment 1

[0031]① Weigh 300 mg of ferrocene (analytical pure) and 500 mg of melamine (analytical pure), mix them and grind them thoroughly in a mortar until they are evenly mixed. ② Foam Ni was placed in acetone for ultrasonication, washed with distilled water, then ultrasonicated with ethanol, and washed with distilled water. Put the foamed Ni after ② treatment on the stage, and put it into the constant temperature zone of the reaction chamber. Ar(60cm 3 / min) as the protective gas and ethylene as the carbon source. After reaching the set temperature, slowly add ① into the reaction chamber to obtain the composite structure battery positive electrode of nitrogen-doped carbon nanotube foam Ni network. Use the 2016 button battery case as the battery package, place the lithium sheet, Celgard2340, and the electrode on the negative electrode case of the battery in turn, add some organic electrolyte for lithium-air batteries on the electrode until the electrode and the membrane are complete...

Embodiment 2

[0033] ① Weigh 300 mg of ferrocene (analytical pure) and 500 mg of melamine (analytical pure), mix them and grind them thoroughly in a mortar until they are evenly mixed. ② Foam Ni was placed in acetone for ultrasonication, washed with distilled water, then ultrasonicated with ethanol, and washed with distilled water. Put the foamed Ni after ② treatment on the stage, and put it into the constant temperature zone of the reaction chamber. Ar(60cm 3 / min) as the protective gas and ethylene as the carbon source. After reaching the set temperature, slowly add ① into the reaction chamber to obtain a composite structure of nitrogen-doped carbon nanotube foam Ni network. ③Put 2g of cobalt nitrate and 2g of sodium nitrate into a blend solution containing 100ml of deionized water and ethanol 1:1 (volume ratio) and stir evenly as an electroplating solution. The composite structure obtained in ② is a working electrode, a platinum sheet electrode As the counter electrode, the saturated ...

Embodiment 3

[0035] ① Weigh 300 mg of ferrocene (analytical pure) and 500 mg of melamine (analytical pure), mix them and grind them thoroughly in a mortar until they are evenly mixed. ② Foam Ni was placed in acetone for ultrasonication, washed with distilled water, then ultrasonicated with ethanol, and washed with distilled water. Put the foamed Ni after ② treatment on the stage, and put it into the constant temperature zone of the reaction chamber. Ar(60cm 3 / min) as the protective gas and ethylene as the carbon source. After reaching the set temperature, slowly add ① into the reaction chamber to obtain a composite structure of nitrogen-doped carbon nanotube foam Ni network. ③Put 2g of cobalt nitrate and 2g of sodium nitrate into a blend solution containing 100ml of deionized water and ethanol 1:1 (volume ratio) and stir evenly as an electroplating solution. The composite structure obtained in ② is a working electrode, a platinum sheet electrode As the counter electrode, the saturated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com