A kind of environment-friendly fuel oil for special vehicles

A technology for special automobiles and fuel oil, which is applied in the preparation of environmentally friendly fuels and green fields. It can solve the problems of insufficient synthesis and refining technology of crude esters, large investment in hydrogenation equipment, high freezing point, and high cold filter point. Complementary, high viscosity, and the effect of increasing the flash point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1. Refining of Crude Biodiesel

[0031] Put 100kg of crude methyl ester into the reaction tank with mechanical stirring, heating and vacuum dehydration device, raise the temperature to 65°C under stirring, add 0.5kg of sulfuric acid-acetic acid mixture until the pH is 5, after stirring evenly, slowly add 1kg35wt % hydrogen peroxide, keep oxidative decolorization at 65°C for 1 hour, stop stirring, let it stand still, release oxidation residue and water from the bottom valve of the reaction tank;

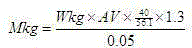

[0032] After determining the acid value AV=5mgKOH / g, add caustic soda and diethanolamine mixed solution according to the calculated amount, stir for 15 minutes, let it stand for stratification, release "soap stock" from the bottom valve of the reaction tank, and measure the acid value after treatment AV= 0.5mgKOH / g, then add 5% concentrated saline to wash, and then wash with deionized water. After separating the lower layer of washing water, turn on the vacuum system and raise...

Embodiment 2

[0043] 1. Refining of Crude Biodiesel

[0044] Put 100kg of crude methyl ester into the reaction tank with mechanical stirring, heating, and vacuum dehydration device, heat up to 70°C under stirring, add 0.5kg of sulfuric acid-acetic acid mixture until the pH is 6, after stirring evenly, slowly add 3kg35wt % hydrogen peroxide, keep oxidative decolorization at 70°C for 1 hour, stop stirring, let stand, and release oxidation residue and water from the bottom valve of the reaction tank;

[0045] After measuring the acid value AV=3mgKOH / g, add caustic soda and diethanolamine mixed solution according to the calculated amount, stir for 15 minutes, let it stand for stratification, release "soap stock" from the bottom valve of the reaction tank, and measure the acid value after treatment AV= 0.5mgKOH / g, then add 5wt% concentrated saline to wash, and then wash with deionized water. After separating the lower layer of washing water, turn on the vacuum system and raise the temperature t...

Embodiment 3

[0056] 1. Refining of Crude Biodiesel

[0057] Put 100kg of crude methyl ester into the reaction tank with mechanical stirring, heating, and vacuum dehydration device, heat up to 68°C under stirring, add 0.5kg of sulfuric acid-acetic acid mixture until the pH is 5, after stirring evenly, slowly add 2kg35wt % hydrogen peroxide, kept at 68°C for oxidative decolorization for 1 hour, stopped stirring, let stand, and released oxidation residue and water from the bottom valve of the reaction tank;

[0058] After determining the acid value AV=6mgKOH / g, add caustic soda and diethanolammonium mixture according to the calculated amount, stir for 15 minutes, let stand for stratification, release "soap foot" from the bottom valve of the reaction tank, and measure the acid value AV after treatment =0.5mgKOH / g, then add 5wt% salt water to wash, and then wash with deionized water. After separating the lower layer of washing water, turn on the vacuum system and raise the temperature to 90°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com