Mesoporous carbon material, elemental sulfur and preparation method for mesoporous carbon composite material

A composite material, mesoporous carbon technology, applied in electrical components, electrochemical generators, battery electrodes, etc., can solve problems such as deterioration of ionic conductivity, loss of active materials, and poor cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

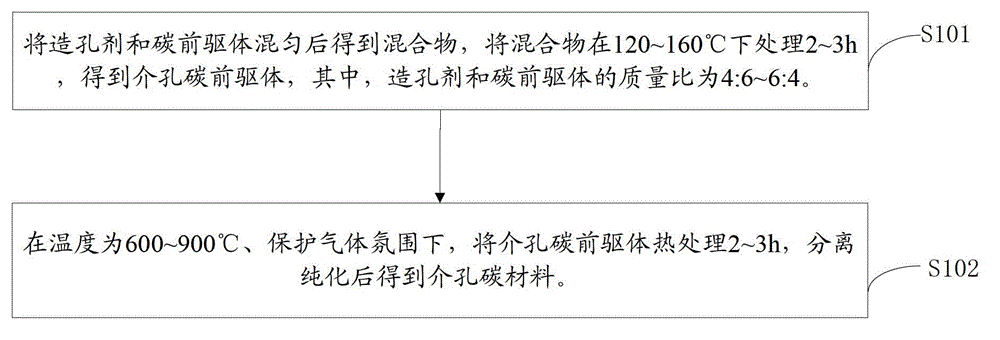

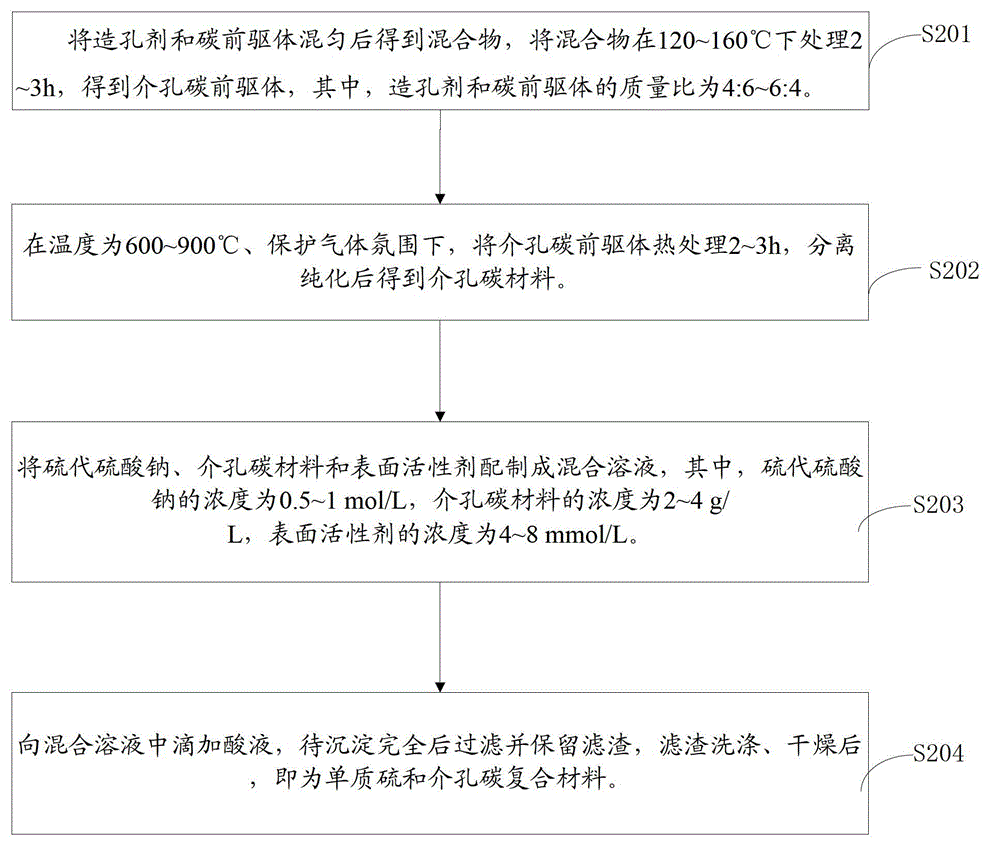

[0039] see figure 1 , the preparation method of the mesoporous carbon material of an embodiment, comprises the following steps:

[0040] Step S101: Mix the pore-forming agent and the carbon precursor to obtain a mixture, and treat the mixture at 120-160° C. for 2-3 hours to obtain a mesoporous carbon precursor, wherein the mass ratio of the pore-forming agent to the carbon precursor is 4:6~6:4.

[0041]The operation of mixing the pore-forming agent and the carbon precursor to obtain the mixture is: dissolving the pore-forming agent in the first solvent to prepare a pore-forming agent solution, dissolving the carbon precursor in the second solvent to prepare a carbon precursor solution , mixing the pore-forming agent solution and the carbon precursor solution to obtain a mixed solution, drying the mixed solution and removing excess water to obtain a mixture. For example, the mixed solution was heated and evaporated at 80° C. for 6 h under magnetic stirring to remove excess wa...

Embodiment 1

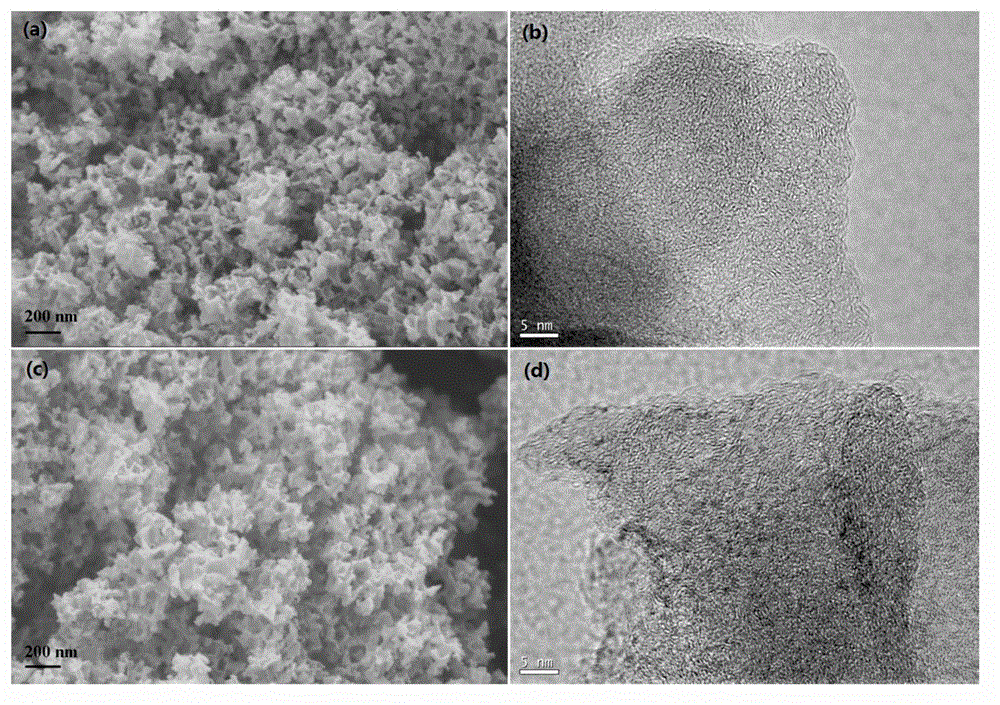

[0067] Preparation of Mesoporous Carbon Materials

[0068] In this example, the hard template method was used to prepare the mesoporous carbon material, and the nano-calcium carbonate used was nano-calcium carbonate (American Special Minerals Corporation). Specifically include the following steps:

[0069] Mix the nano-calcium carbonate and carbon precursor sucrose at a mass ratio of 4:6. Specifically, dissolve 8 g of nano-calcium carbonate in 20 ml of ethanol, and then mix with 0.2 L of 0.175 mol / L sucrose solution. The mixture was heated and evaporated at 80°C for 6h under magnetic stirring to remove the moisture inside, and then dried at 160°C for 2h pre-carbonization.

[0070] Finally, carbonization was carried out at 800 °C for 2 h in a tube furnace under a nitrogen atmosphere. The high-temperature carbonized product was placed in dilute hydrochloric acid to remove nano-calcium carbonate, and after drying, 3 g of mesoporous carbon material was obtained, with a yield of ...

Embodiment 2

[0072] Preparation of Mesoporous Carbon Materials

[0073] In this example, the hard template method was used to prepare the mesoporous carbon material, and the nano-alumina used was nano-alumina (American Special Minerals Corporation). Specifically include the following steps:

[0074] Mix nano-alumina and carbon precursor glucose at a mass ratio of 6:4. Specifically, dissolve 12g of nano-alumina in 20ml of ethanol, and then mix with 0.2L of 0.12mol / L glucose solution. The mixture was heated and evaporated at 80°C for 6h under magnetic stirring to remove the moisture inside, and then dried at 120°C for 2.5h pre-carbonization.

[0075] Finally, it was carbonized at 600°C for 2.5h in a tube furnace under a nitrogen atmosphere. The high-temperature carbonized product was placed in dilute hydrochloric acid to remove nano-alumina, and 2 g of mesoporous carbon material was obtained after drying, with a yield of about 25%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com