A kind of method for solidifying chromium in polluted acid residue

A technology of polluted acid slag and magnesium slag, applied in the direction of solid waste removal, etc., can solve problems such as threats to human health, toxic effects, and damage to human health, and achieve the effects of low raw material cost, simple curing process, and easy engineering implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) The modified metal magnesium slag in the raw materials is the magnesium smelting slag of Ningxia Huiye Magnesium Industry Group Co., Ltd., and the polluted acid slag is the slag of the lead-zinc smelting enterprise (Zhuzhou Smelting Group Co., Ltd.).

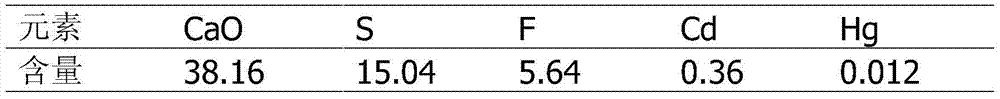

[0021] Chemical composition of polluted acid slag (%)

[0022]

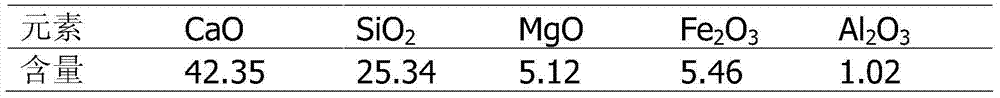

[0023] Chemical composition of modified magnesium slag (%)

[0024]

[0025] (2) Drying: collect the dirty acid slag and dry it at 110°C until the moisture content is ≤3%;

[0026] (3) Grinding: put the dried dirty acid slag into a vibrating mill for dry grinding, and the grinding time is 8 minutes. At the same time, take the modified metal magnesium slag and carry out ultrafine grinding, and use a vibrating mill for grinding for 5 minutes;

[0027] (4) Mixing: add ultra-finely pulverized modified magnesium slag to the ground polluted acid slag and mix for 40 minutes, wherein the added amount of magnesium slag accounts for 70% of the total weight ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com