A fast dehydration curing agent

A rapid dehydration and curing agent technology, which is applied in the direction of fixed/solidified sludge treatment, water pollutants, chemical instruments and methods, etc., can solve the problem of high pH value of dehydrated and solidified sediment cake and tail water, low heavy metal leaching content, Unsatisfactory curing effect and other problems, to achieve the effect of meeting the environmental capacity requirements, accelerating coagulation and settlement, and high unconfined compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

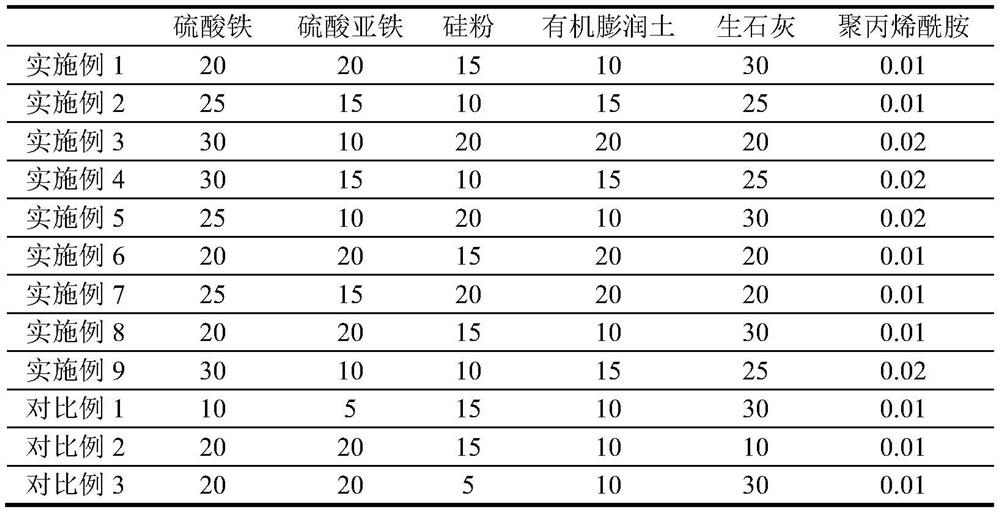

Examples

Embodiment 1

[0039] A rapid dehydration curing agent, including the following components:

[0040] 20 parts of iron sulfate,

[0041] 20 parts of ferrous sulfate,

[0042] 15 parts of silicon powder,

[0043] 10 parts of organic bentonite,

[0044] 30 parts of quicklime,

[0045] 0.01 parts of polyacrylamide (M=12 million).

[0046] The preparation method of described dehydration curing agent is as follows:

[0047] Accurately weigh the components in parts by weight, mix and grind until the particle size is less than 200 mesh, and obtain the product.

[0048] Sludge treatment method using fast dehydration curing agent:

[0049] The fast dehydration solidifying agent that is prepared is added to the sludge of a certain lake in Guangzhou (the initial moisture content is 88.3%, the lead leaching content is 9.26mg / kg, the mercury leaching content is 0.56mg / kg, and the arsenic leaching content is 7.56mg / kg. kg) in solidification test; the addition of the solidifying agent is 10% of the s...

Embodiment 2

[0051] A rapid dehydration curing agent, including the following components:

[0052] 25 parts of iron sulfate,

[0053] 15 parts of ferrous sulfate,

[0054] 10 parts of silicon powder,

[0055] 10 parts of organic bentonite,

[0056] 15 parts quicklime,

[0057] 0.01 part of polyacrylamide (M=12 million).

[0058] The preparation method of described dehydration curing agent is as follows:

[0059] Accurately weigh the components in parts by weight, mix and grind until the particle size is less than 200 mesh, and obtain the product.

[0060] Sludge treatment method using fast dehydration curing agent:

[0061]The fast dehydration solidifying agent that is prepared is added to the sludge of a certain lake in Guangzhou (the initial moisture content is 88.3%, the lead leaching content is 9.26mg / kg, the mercury leaching content is 0.56mg / kg, and the arsenic leaching content is 7.56mg / kg. kg) in solidification test; the addition of the solidifying agent is 10% of the sludge...

Embodiment 3

[0063] A rapid dehydration curing agent, including the following components:

[0064] 30 parts of iron sulfate,

[0065] 10 parts of ferrous sulfate,

[0066] 20 parts of silicon powder,

[0067] 20 parts of organic bentonite,

[0068] 20 parts quicklime,

[0069] 0.02 parts of polyacrylamide (M=12 million).

[0070] The preparation method of described dehydration curing agent is as follows:

[0071] Accurately weigh the components in parts by weight, mix and grind until the particle size is less than 200 mesh, and obtain the product.

[0072] Sludge treatment method using fast dehydration curing agent:

[0073] The fast dehydration solidifying agent that is prepared is added to the sludge of a certain lake in Guangzhou (the initial moisture content is 88.3%, the lead leaching content is 9.26mg / kg, the mercury leaching content is 0.56mg / kg, and the arsenic leaching content is 7.56mg / kg. kg) in solidification test; the addition of the solidifying agent is 10% of the slud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com