Non-noble metal catalyst for fuel cells, and its application

A non-precious metal and fuel cell technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, battery electrode, etc., can solve the problems of catalyst loss, stability gap, etc., achieve short cycle time, Wide range of applications and good application effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

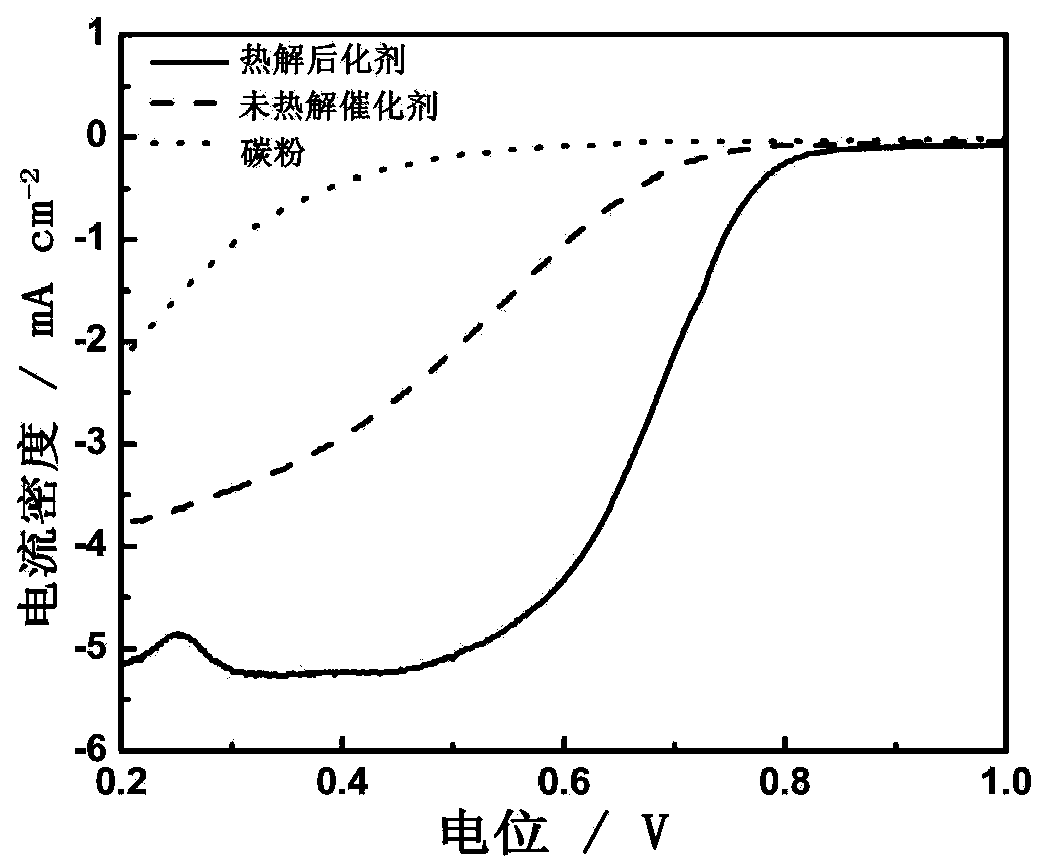

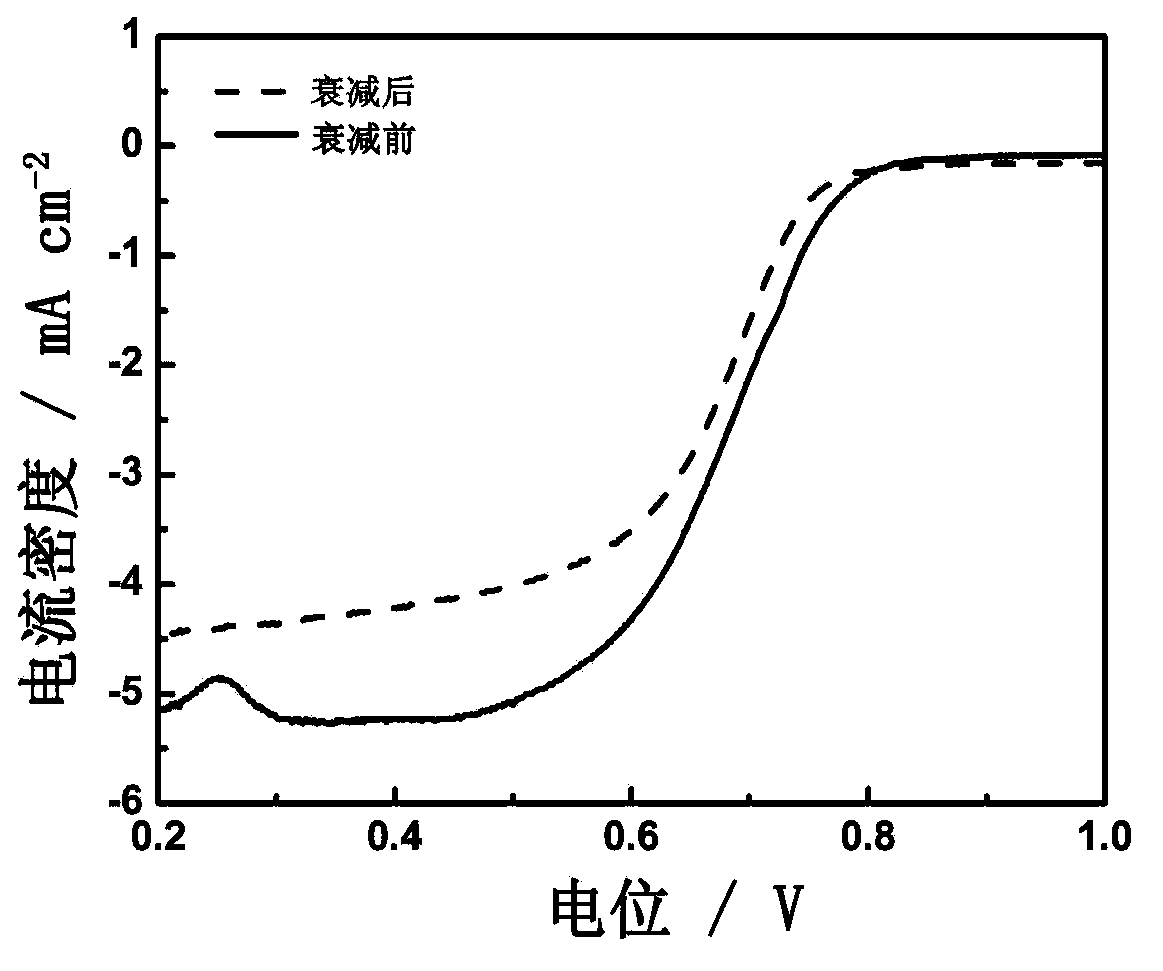

[0034]Dissolve 6.16 g of resorcinol in 7 mL of deionized water to form a transparent solution A; add 9.08 g of formaldehyde solution with a mass concentration of 37% to the transparent solution A and stir for 5 hours to prepare the sol-gel precursor B. Add 3 mL of ammonia water with a mass concentration of 28% dropwise in an environment at 20°C and continue to seal and stir to form gel C; transfer gel C to a vacuum oven for 7 days of vacuum drying and aging treatment at 60°C, take it out, and grind it to obtain Solid powder D; carbonize the solid powder D at 800° C. for 1 h in a nitrogen atmosphere to obtain the desired carbon gel carrier. Dissolve 300 mg of 2-(2-pyridine)-benzimidazole in 20 mL of deionized water, and stir for one hour under nitrogen protection until it is completely dissolved. Then add 0.1 g of ferrous sulfate, and continue stirring for two hours until the complex is completely formed. Add 0.1 g of the prepared carbon gel carrier, stir for 2 h under the pro...

Embodiment 2

[0040] Dissolve 6.16 g of resorcinol in 7 mL of deionized water to form a transparent solution A; add 9.08 g of formaldehyde solution with a mass concentration of 37% to the transparent solution A and stir for 5 hours to prepare the sol-gel precursor B. Add 3 mL of ammonia water with a mass concentration of 28% dropwise in an environment at 20°C and continue to seal and stir to form gel C; transfer gel C to a vacuum oven for 7 days of vacuum drying and aging treatment at 60°C, take it out, and grind it to obtain Solid powder D; carbonize the solid powder D at 800° C. for 1 h in a nitrogen atmosphere to obtain the desired carbon gel carrier. Dissolve 300 mg of 2-(2-pyridine)-benzimidazole in 20 mL of deionized water, and stir for one hour under nitrogen protection until it is completely dissolved. Then add 0.1 g of cobalt nitrate and continue to stir for two hours until the complex is completely formed. Add 0.1 g of the prepared carbon gel carrier, stir for 2 h under the prote...

Embodiment 3

[0042] Dissolve 6.16 g of resorcinol in 7 mL of deionized water to form a transparent solution A; add 9.08 g of formaldehyde solution with a mass concentration of 37% to the transparent solution A and stir for 5 hours to prepare the sol-gel precursor B. Add 3 mL of ammonia water with a mass concentration of 28% dropwise in an environment at 20°C and continue to seal and stir to form gel C; transfer gel C to a vacuum oven for 7 days of vacuum drying and aging treatment at 60°C, take it out, and grind it to obtain Solid powder D; carbonize the solid powder D at 800° C. for 1 h in a nitrogen atmosphere to obtain the desired carbon gel carrier. Dissolve 300 mg of 2-(2-pyridine)-benzimidazole in 20 mL of deionized water, and stir for one hour under nitrogen protection until it is completely dissolved. Then add 0.1 g of cobalt nitrate and continue to stir for two hours until the complex is completely formed. Add 0.2 g of the prepared carbon gel carrier, stir for 2 h under the prote...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com