Extraction method for flavor components in tobacco and application of extraction method

An aroma component and extraction method technology, which is applied in the field of ultrasonic crushing and extraction of tobacco aroma components, can solve the problems of chemical reaction affecting the structure and properties of aroma components in tobacco, consumption of large tobacco leaf raw materials, loss of aroma components, etc., so as to reduce the loss of aroma components, The effect of reducing waste of tobacco leaves and high extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] The sample is sliced tobacco shredded after re-roasting tobacco leaves in Jilin production area. The shredded tobacco was placed in a blast drying oven, and treated at 50° C. for 4 hours under drying temperature conditions. Then accurately weigh 0.5g of shredded tobacco, put it into a 50mL round-bottomed plastic tube with a screw cap, add 10mL of absolute ethanol, and place it in an ice-water bath for freezing and impregnating for 5 minutes; The ultrasonic horn was inserted into the extraction solvent, the ultrasonic power was set to 665W, the continuous ultrasonic time was 3s, the intermittent time was 9s, the cycle was carried out and the total ultrasonic time was 20min, and the shredded tobacco was crushed by ultrasonic waves. After the ultrasonic crushing is completed, seal the container and continue to immerse and extract for 5 minutes. Transfer the mixed slurry into a 2mL centrifuge tube through a pipette, set the centrifugation speed to 5000rpm, and centrifuge...

Embodiment 2

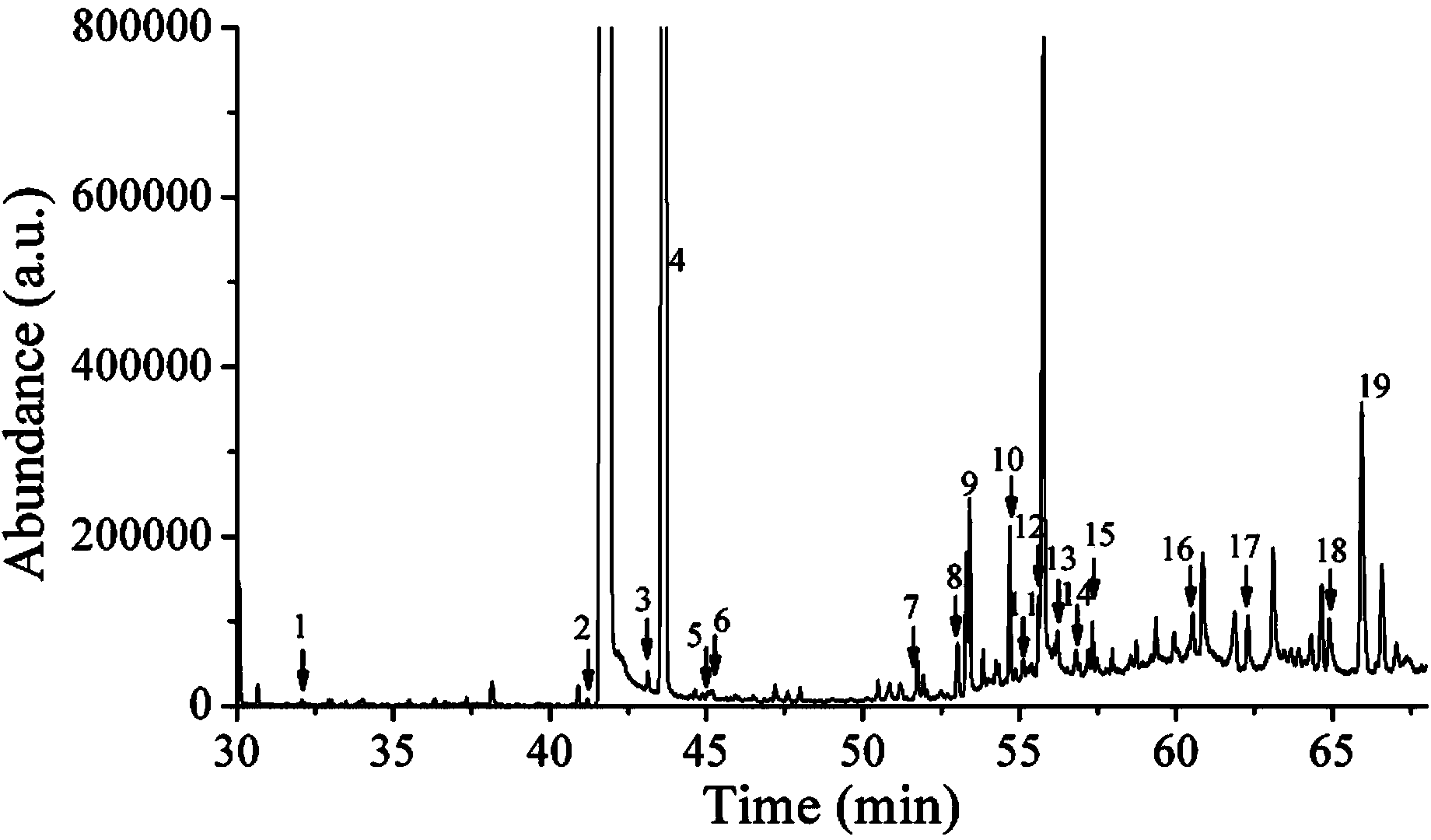

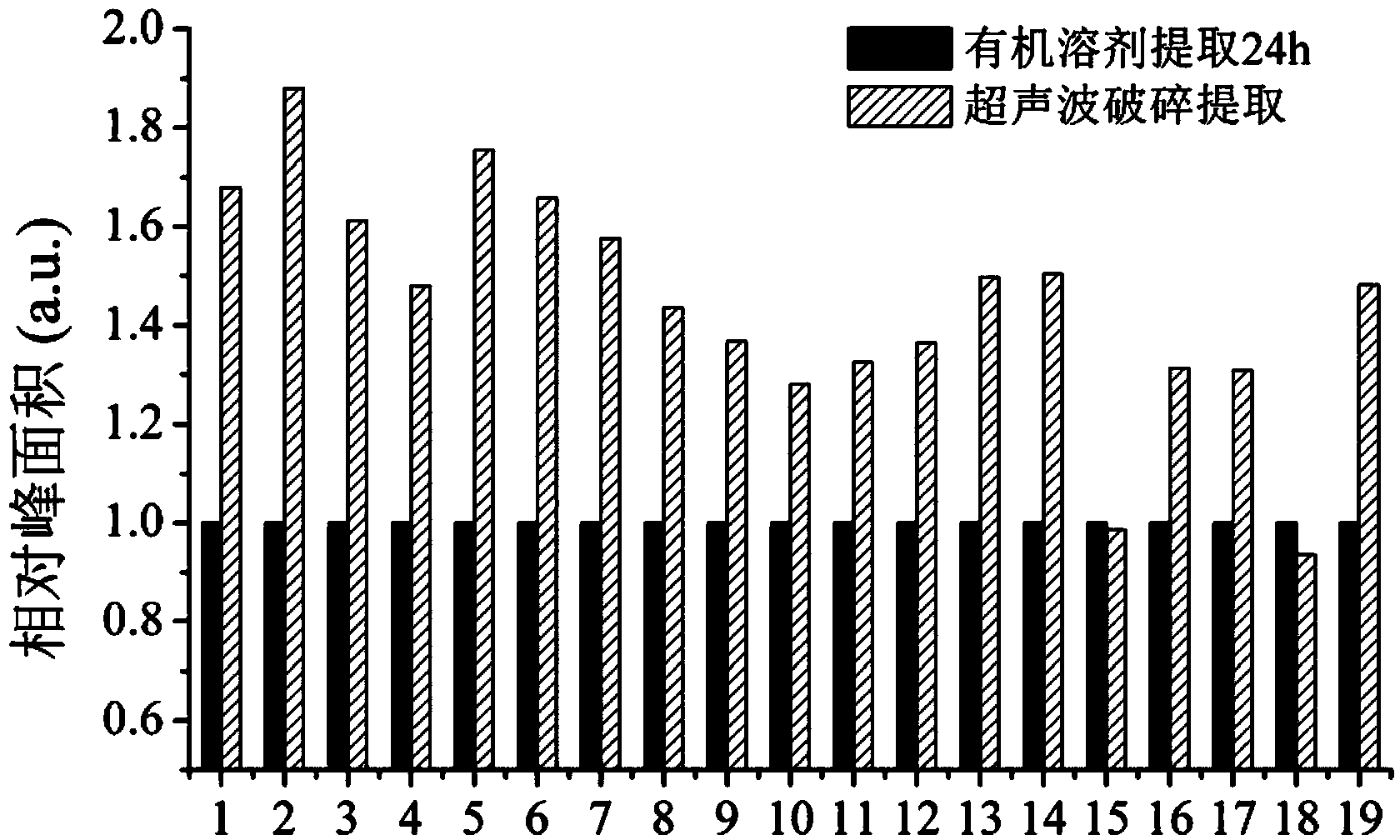

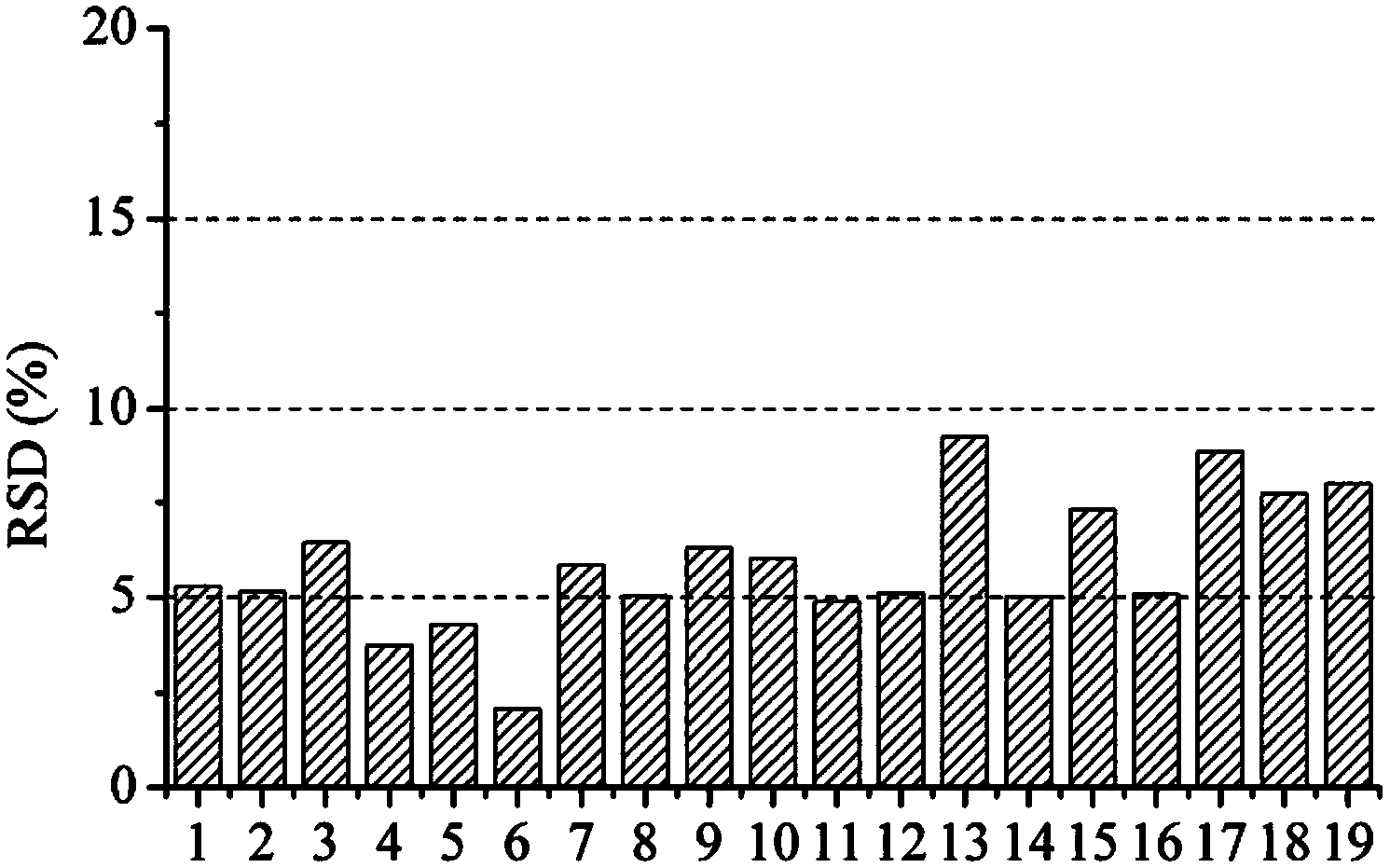

[0073] The solution to be tested containing tobacco aroma components extracted by ultrasonic crushing in the above-mentioned Example 1 was determined by gas chromatography-mass spectrometry. Simultaneously, with the same sample in above-mentioned embodiment 1, add internal standard, adopt organic solvent extraction method to extract, extraction time is 24h, the extraction liquid that will obtain also adopts gas chromatography-mass spectrometry to measure, the gas chromatography of two kinds of extraction methods The determination conditions of mass spectrometry were the same, the NIST05 database (matching degree ≥ 90) was used for qualitative analysis, and the internal standard method was used for semi-quantitative analysis. For specific test results, see Figure 1-2 ,Table 1.

[0074] It can be seen from Table 1 that the chromatographic peak area of the aroma components of the extract obtained by ultrasonic crushing extraction technology is significantly larger than that o...

Embodiment 3

[0078] The sample is the sliced tobacco leaves after re-roasting the tobacco leaves in Anhui production area. The tobacco leaves were placed in a constant temperature and humidity box, and balanced for 48 hours at 25° C. and 60% humidity. Cut it into pieces with scissors, and control the size within 1.5cm×1.5cm, then accurately weigh 1g of the cigarette slices, put it into a 50mL round-bottomed plastic tube with a screw cap, add 30mL of methanol, and place it in an ice-water bath for 5 minutes of freezing and impregnation; Put the solution in the ultrasonic breaker, insert a 6mm diameter ultrasonic horn into the extraction solvent, set the ultrasonic power to 665W, the continuous ultrasonic time to 3s, the intermittent time to 9s, and the cycle is carried out and the total ultrasonic time is 15min. Crush the flakes. After the ultrasonic crushing is completed, seal the container and continue to immerse and extract for 5 minutes. Transfer the mixed slurry into a 2mL centrifu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com