Manufacturing method of shallow trench isolation structure

A technology of isolation structure and manufacturing method, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as narrow width effect, field silicon oxide intrusion, hard mask pull-back distance increase, etc., to meet the requirements of the process required effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

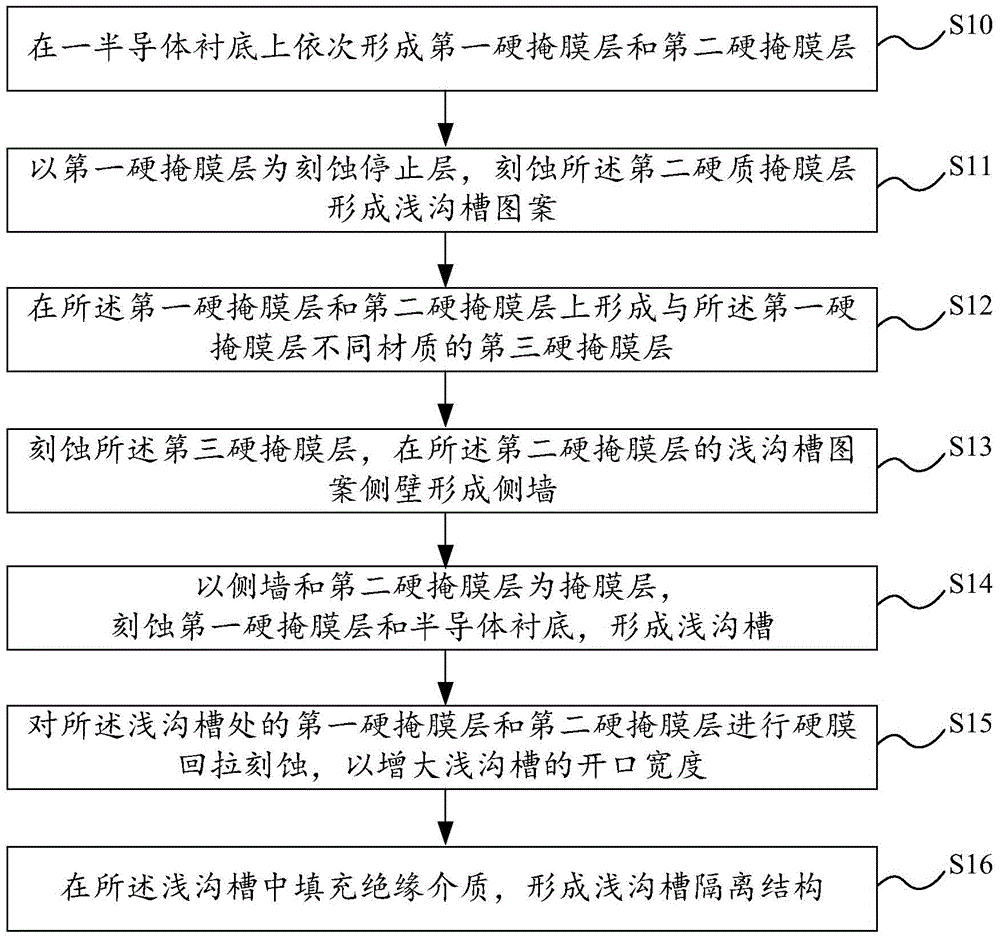

[0033] Such as figure 1 As shown, this embodiment provides a method for manufacturing a shallow trench isolation structure, including the following steps:

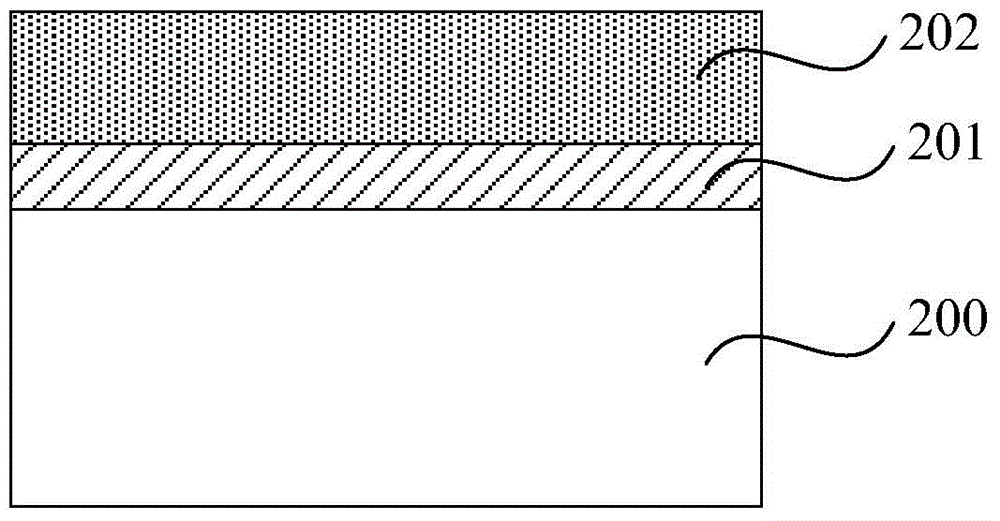

[0034] S10, sequentially forming a first hard mask layer and a second hard mask layer on a semiconductor substrate;

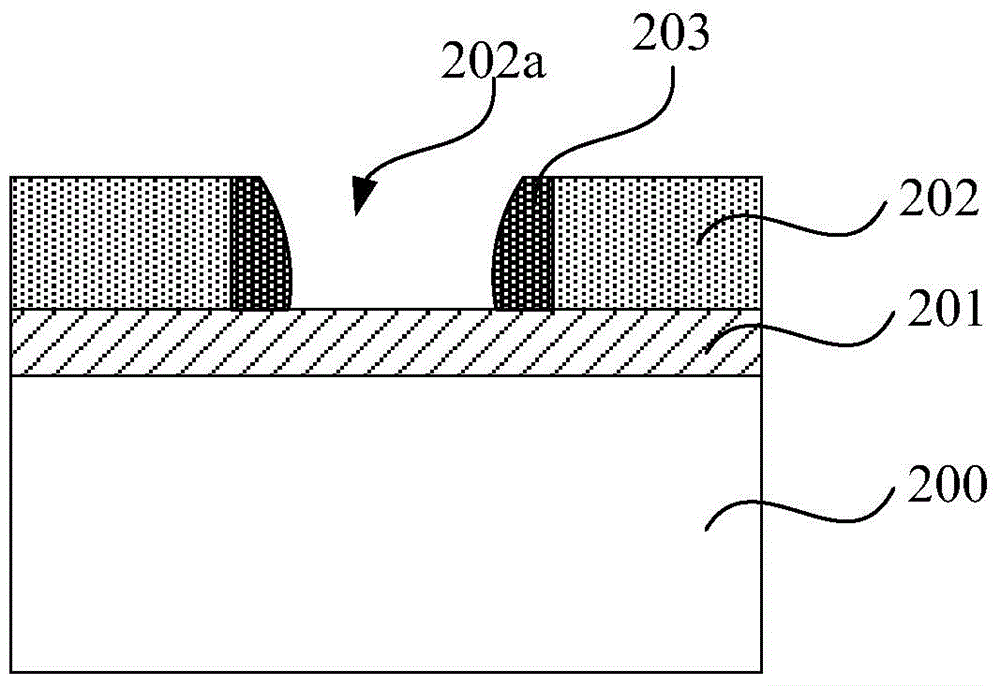

[0035] S11, using the first hard mask layer as an etching stop layer, etching the second hard mask layer to form a shallow trench pattern;

[0036] S12, forming a third hard mask layer of a material different from that of the first hard mask layer on the first hard mask layer and the second hard mask layer;

[0037] S13, etching the third hard mask layer to form sidewalls on the sidewalls of the shallow trench pattern of the second hard mask layer;

[0038] S14, using the sidewalls and the second hard mask layer as mask layers, etching the first hard mask layer and the semiconductor substrate to form shallow trenches;

[0039] S15, performing hard mask pull-back etching on the first hard mask layer and t...

Embodiment 2

[0050] Such as image 3 As shown, this embodiment provides a method for manufacturing a shallow trench isolation structure, including the following steps:

[0051] S30, sequentially forming a first hard mask layer and a second hard mask layer on a semiconductor substrate;

[0052] S31, using the first hard mask layer as an etching stop layer, etching the second hard mask layer to form a shallow trench pattern;

[0053] S32, forming a third hard mask layer made of the same material as the first hard mask layer on the first hard mask layer and the second hard mask layer;

[0054] S33, etching the third hard mask layer to form sidewalls on the sidewalls of the shallow trench pattern in the second hard mask layer;

[0055] S34, using the sidewalls and the second hard mask layer as mask layers, etching the first hard mask layer and the semiconductor substrate to form shallow trenches;

[0056] S35, performing hard mask pull-back etching on the first hard mask layer and the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com