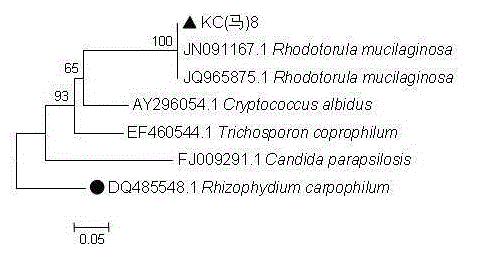

Rhodotorula mucilaginosa and application in fermentation production of carotenoid and oils

A gum rhodotorula and carotene technology, applied in the field of yeast, can solve the problems of long production cycle and complicated cultivation process, and achieve good application prospects and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

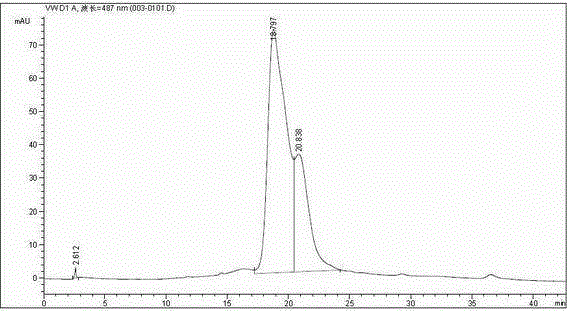

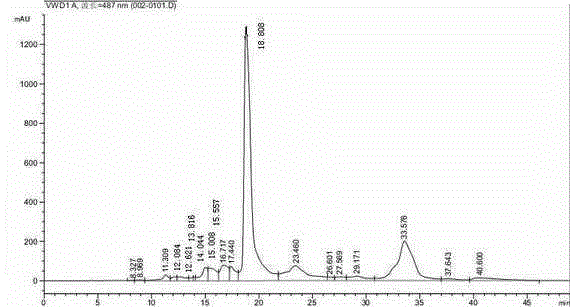

[0025]Slant culture and seed culture are carried out on the rhodotorula gluei to obtain activated seed solution; the seed solution is inoculated into the carotenoid-producing fermentation medium according to the inoculation amount of 10% by volume, at 27-30°C, pH4.5 -8.0, carbon-to-nitrogen ratio 25-35:1, 190rpm shaking culture for 96h, the fermented liquid containing carotenoids can be obtained, wherein the carbon source is glucose or sucrose, glucose is the best, and the highest yield of carotenoids can reach 22.93 mg / L, the composition of the carotenoid-producing fermentation medium in g / L is: glucose 31.8, yeast extract 1, ammonium sulfate 2, potassium dihydrogen phosphate 1, anhydrous calcium chloride 0.1, magnesium sulfate heptahydrate 0.5, sodium chloride 0.1, the rest is water, pH7.0. The pigments produced are determined by high performance liquid chromatography, and the main components are carotenoids, such as figure 2 and image 3 shown.

[0026] The strain can p...

Embodiment 2

[0028] Slant culture and seed culture of the Rhodotorula gluei are carried out to obtain activated seed liquid; the seed liquid is inoculated into the oil-producing fermentation medium according to the inoculation amount of 10% by volume, at 26-30°C, pH4.5-8.0 , carbon-nitrogen ratio 30-130:1, 190rpm shaking culture for 96h, the fermented liquid containing oil can be obtained, wherein the carbon source is glucose or sucrose, and the oil can be produced under the condition of glucose and sucrose as the carbon source, and the highest oil produced can reach 27.8%, the composition of the oil-producing fermentation medium is calculated in g / L: glucose 85.6, yeast extract powder 0.5, potassium dihydrogen phosphate 1, ammonium sulfate 2, magnesium sulfate heptahydrate 0.5, and the remaining ingredients are water, pH6. 0, using Soxhlet extraction method for oil extraction, after GC-MS to identify the produced oil, the produced oil is mainly C16 and C18 unsaturated fatty acids, such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com