A kind of beneficiation method of copper-zinc ore containing easy pumice gangue

A beneficiation method and technology of copper and zinc sulfide, which are applied in flotation, solid separation and other directions, can solve the problems of low and low zinc recovery rate, and achieve the effect of strengthening zinc recovery, improving recovery rate and improving recovery rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

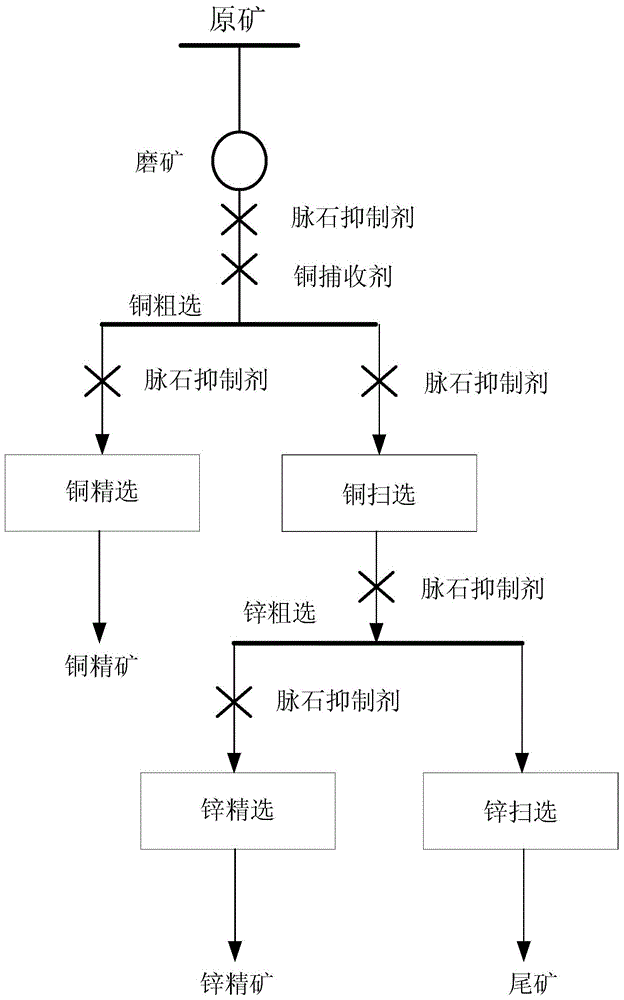

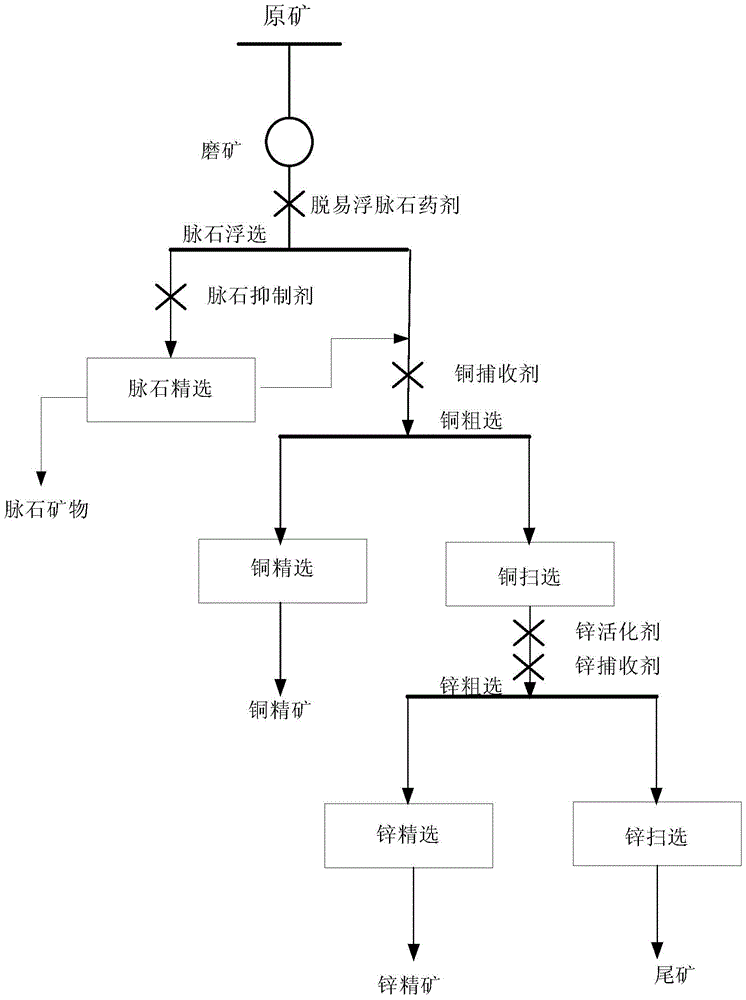

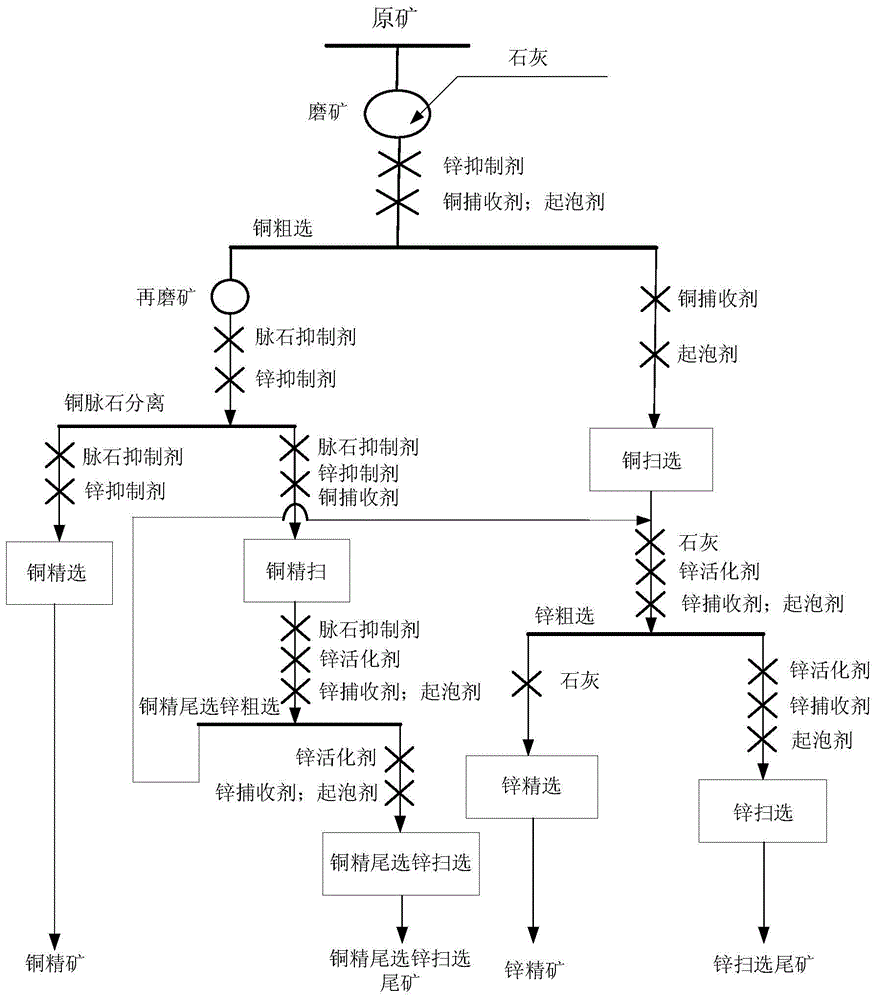

Method used

Image

Examples

Embodiment 1

[0077] In the raw ore of a copper-zinc sulfide mine in Xinjiang, by weight percentage, the chalcopyrite content is 3.2%, the sphalerite content is 3.4%, the pyrite content is 1.9%, the talc content is 23.2%, and the calcite content is 15.2%. %, the overall content of sericite and chlorite is 20.8%, the overall content of quartz and feldspar is 27.1%, and the content of amphibole is 4.6%.

[0078] Adopt the copper-zinc sulfide ore beneficiation method of the embodiment of the present invention to carry out beneficiation to this raw ore, its concrete steps are as follows:

[0079] (1) The step of ore grinding: add the raw ore and lime of copper sulfide zinc ore to the ball mill, the consumption of lime is 1500g / t, and add water to the raw ore and lime in the ball mill, the liquid-solid ratio of water to raw ore and lime 1:1; after adding water, grind the ore until the ore with a particle size of no more than 0.074mm accounts for 85% of the total weight of the raw ore, stop the g...

Embodiment 2

[0095] In the raw ore of a copper-zinc sulfide mine in Yunnan, it contains 0.23% copper and 3.16% zinc by weight percentage. Metal minerals mainly include chalcopyrite, sphalerite, magnetite, pyrrhotite, pyrite, and cassiterite; gangue minerals include pyroxene, quartz, mica, chlorite, calcite, talc, feldspar, Fluorite, apatite, titanite, andandrite, etc.

[0096] The copper sulfide-zinc ore beneficiation method in the embodiment of the present invention is used to beneficiate the raw ore, and the beneficiation result is as follows: by weight percentage, in the obtained copper concentrate, the copper grade is 18.54%, and the copper recovery rate is 66.72%. ; In the obtained zinc concentrate, the zinc grade is 46.07%, and the zinc recovery rate is 86.29%.

[0097] The raw ore is beneficiated by the sulfide ore beneficiation method in the prior art; the beneficiation results are as follows: by weight percentage, in the obtained copper concentrate, the copper grade is 15.44%, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com