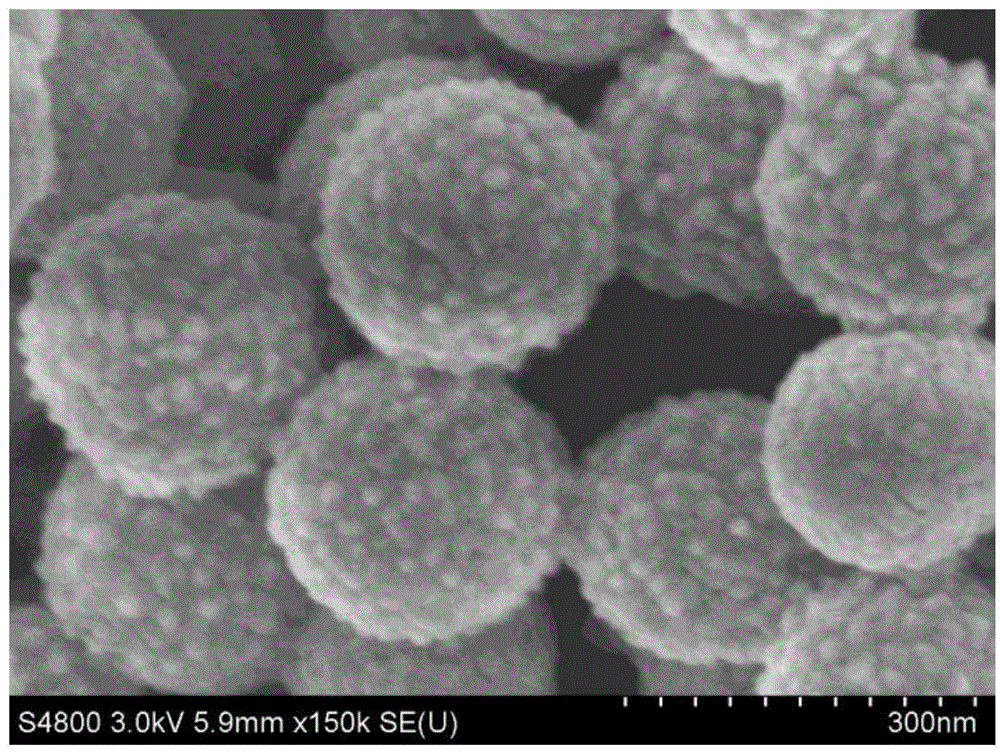

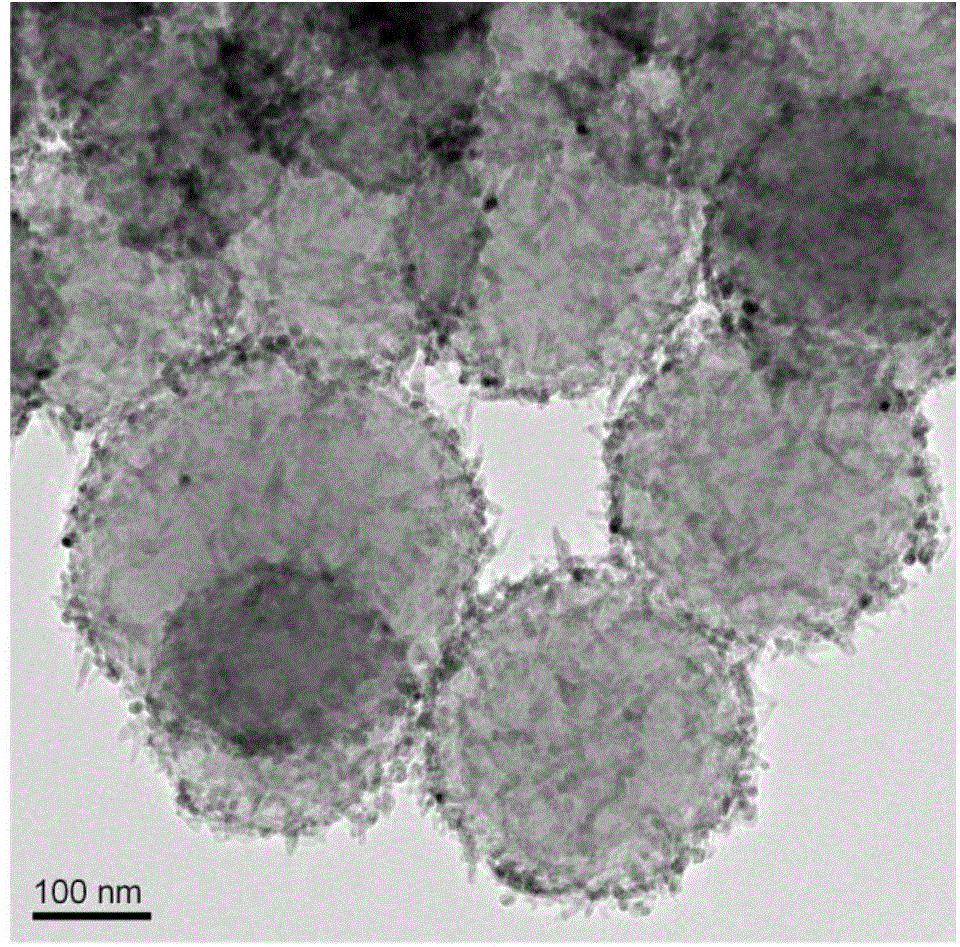

Bismuth-tungstate-modified magnetic-separation hollow composite photocatalyst and preparation method thereof

A technology of magnetic separation and bismuth tungstate, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of unsatisfactory photocatalyst catalytic effect and achieve Effects of promoting application potential, high preparation efficiency, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of the above bismuth tungstate modified magnetic separation hollow composite photocatalyst, the specific preparation steps are as follows:

[0032] Step 1, adopting traditional hydrothermal reaction to prepare phenolic resin microspheres;

[0033] The preparation volume ratio is 1:(10~100):(59~179) ammoniacal liquor, the mixed solution of ethanol and water, wherein the concentration of ammoniacal liquor is 25%; Resorcinol and concentration are 37% formalin solution Add the above mixed solution, place it in a water bath at 10-60°C and stir for 10 hours, wherein the mass volume ratio of resorcinol and mixed solution is 1: (70-280) g / ml, formalin solution and mixed solution The volume ratio of the solution is 1: (50-200); transfer the solution to a hydrothermal kettle, and keep it at 100°C for 24h; after natural cooling, wash it with absolute ethanol and deionized water three times, and then dry it at 50°C for 24h , to obtain phenolic resin microsph...

Embodiment 1

[0038] Step 1, mix 59mL of deionized water, 10mL of ethanol and 1mL of 25% ammonia solution, place in a water bath at 15°C, then add 0.25g of resorcinol and 0.35mL of formaldehyde solution, stir in the water bath for 10h, then put The solution was transferred to a hydrothermal kettle and kept at 100°C for 24 hours; after natural cooling, it was rinsed three times with absolute ethanol and deionized water, and then dried at 50°C for 24 hours to obtain phenolic resin microspheres;

[0039] Step 2, mix 10mL of zinc nitrate solution with a concentration of 0.01mol / L and 21mL of ferric nitrate solution with a concentration of 0.01mol / L to form a mixed solution A, disperse 0.155g of phenolic resin microspheres into the mixed solution A, and process 15min, after aging for 3 hours, washed with water and centrifuged for 3 times, then dried in a vacuum oven at 50°C for 24h, and the obtained product was 2 Calcined in medium, slowly heated to 350°C and kept for 1h, then cooled naturally t...

Embodiment 2

[0042] Step 1, mix 179mL of deionized water, 100mL of ethanol and 1mL of 25% aqueous ammonia solution, place in a water bath at 60°C, then add 4g of resorcinol and 5.6mL of formaldehyde solution, stir in the water bath for 10h, and then mix the The solution was transferred to a hydrothermal kettle and kept at 100°C for 24 hours; after natural cooling, it was rinsed three times with absolute ethanol and deionized water, and then dried at 50°C for 24 hours to obtain phenolic resin microspheres;

[0043] Step 2: Mix 10mL of zinc chloride solution with a concentration of 4mol / L and 40mL of ferric chloride solution with a concentration of 4mol / L to form a mixed solution A, disperse 5g of phenolic resin microspheres into the mixed solution A, and ultrasonically treat for 15min , aged for 3 hours, washed with water and centrifuged for 3 times, then dried in a vacuum oven at 50°C for 24 hours, and the obtained product was placed in N 2 Calcined in medium, slowly heated to 1000°C and k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com