Welding Process and Welding Mechanism of Microwave Substrate and Housing

A microwave substrate and welding process technology, applied in welding equipment, manufacturing tools, metal processing equipment, etc., can solve problems such as cracks at the joints of microwave substrates, affecting component reliability, differences in thermal expansion coefficients between microwave substrates and solder, etc., to achieve The process flow is convenient and feasible, the effect of improving grounding and heat dissipation performance, improving electrical performance and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

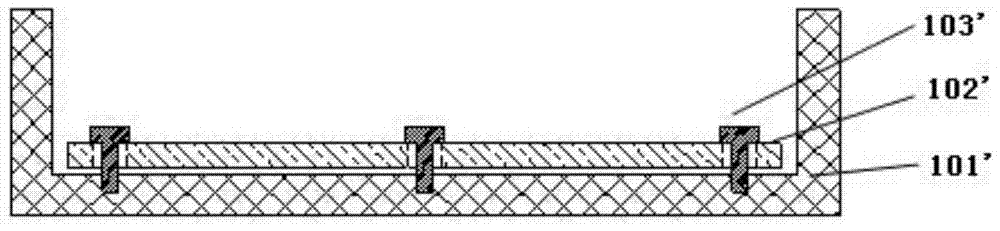

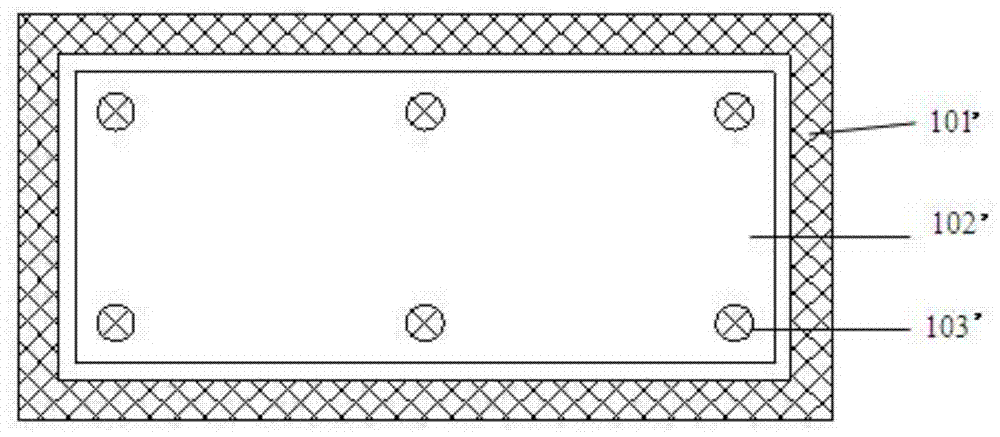

[0046] as attached Figure 5-13 As shown, the present invention relates to a welding process of a microwave substrate and a housing, comprising the following steps:

[0047]Some through holes 801 are processed on the microwave substrate 102. These through holes can be circular through holes, polygonal through holes, irregular through holes, etc., and are not limited, but for the convenience of processing and cost saving, in this embodiment Circular through holes are adopted, and of course the positions of these through holes do not affect the wiring of the microwave substrate.

[0048] A cylinder 601 corresponding to a through hole is processed on the inner bottom surface of the housing 101, the through hole can be used for the cylinder to penetrate, and the aperture of the through hole is larger than the diameter of the cylinder, where the aperture refers to the diameter of the largest diameter cylinder that the through hole can pass through , in this embodiment, the cylinde...

Embodiment 2

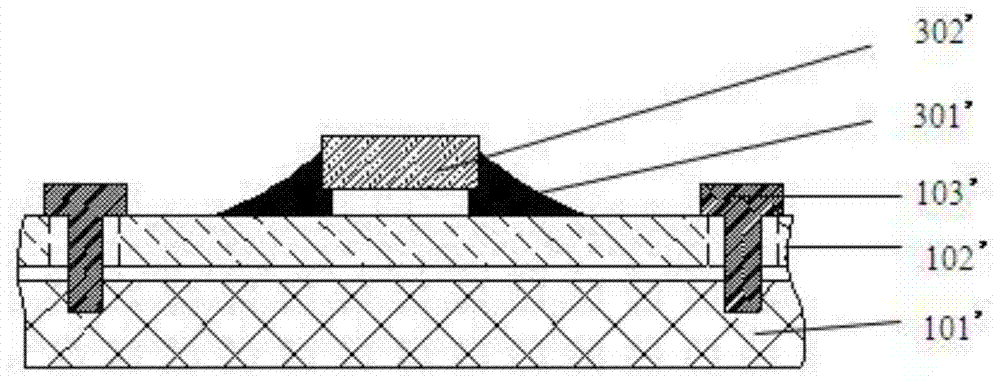

[0058] On the basis of Embodiment 1, some pressure-bearing platforms 1101 with uniform height and larger diameter are evenly made on the upper surface of the microwave substrate. The table height is higher than the circuit traces and components on the microwave substrate, generally greater than 0.5mm. The pressure-bearing table can be a cylindrical surface, and the second pressure block 1201 applies pressure on the microwave substrate through these cylindrical surfaces, thereby ensuring the microwave substrate. Surface cleanliness.

[0059] Applying pressure 1102 can be to apply pressure to the second briquetting block by means of a cylinder, or use a frame beam on the top of the shell, apply pressure to put the shell into the bottom plate, fix the frame beam on the bottom plate, and do it on the beam. out of the screw hole, the screw goes through the screw hole on the beam and against the second pressure block, turn the screw joint to adjust the applied pressure, as shown in ...

Embodiment 3

[0061] like Figure 6-9 As shown, the welding mechanism obtained in the first or second embodiment above includes a microwave substrate 102, a housing 101 and a solder layer 501; a through hole 801 is provided on the microwave substrate, and these through holes 801 can be circular Through holes, polygonal through holes, irregular through holes, etc. are not limited, but in order to facilitate processing and save costs, circular through holes are used in this embodiment. Of course, the positions of these through holes do not affect the wiring of the microwave substrate. The inner bottom surface of the housing is provided with a cylinder corresponding to the through hole. The through hole penetrates into the cylinder. The diameter of the through hole is larger than the diameter of the cylinder, and the height of the cylinder is smaller than the thickness of the microwave substrate. In this embodiment, the cylinder It is a cylinder 601, its diameter is smaller than the diameter o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com