An automatic laser welding arm

A laser welding and laser welding head technology, applied in the field of automatic laser welding arms, can solve the problems of difficult welding, local overheating, affecting the life of the welding arm, etc., to ensure reliability and stability, prevent welding position errors, and improve welding. The effect of firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

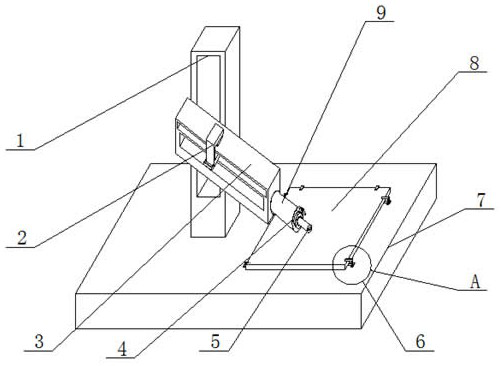

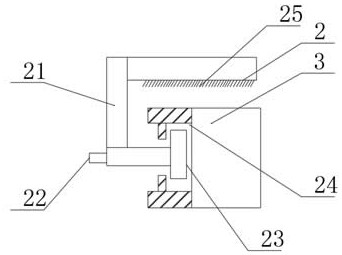

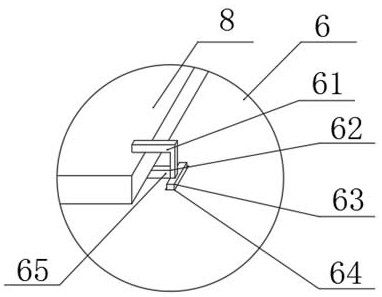

[0026] see Figure 1~4 , in the embodiment of the present invention, an automatic laser welding arm 3 includes a support arm 9, a laser welding head 5 and a shielding gas injection head 14, wherein the laser welding head is provided at the center of the front end of the support arm 9 5. The front end of the support arm 9 is located on the outer peripheral side of the laser welding head 5, and at least one protective gas injection head 14 is provided; it is characterized in that,

[0027] The laser welding head 14 is connected to the support arm 9 by a welding oscillation mechanism 13, and the shielding gas injection head 14 is connected to the support arm 9 by a swing mechanism 12;

[0028] Also includes a controller 11, the controller 11 is set so that: when the laser welding head is welding, the controller controls the welding oscillation mechanism 13 to drive the laser welding head 5 to reciprocate in the width direction of the weld seam and the controller simultaneously c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com