Rare-earth doped modified graphene composite material gas sensitive element for detecting NOx and preparation method of gas sensitive element

A composite material and rare earth doping technology, applied in the direction of material resistance, can solve the problems of low sensitivity of gas sensitive materials, long response time, poor resistance of gas sensor components, etc., to achieve improved gas sensor response, enhanced gas sensor performance, Good electrochemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

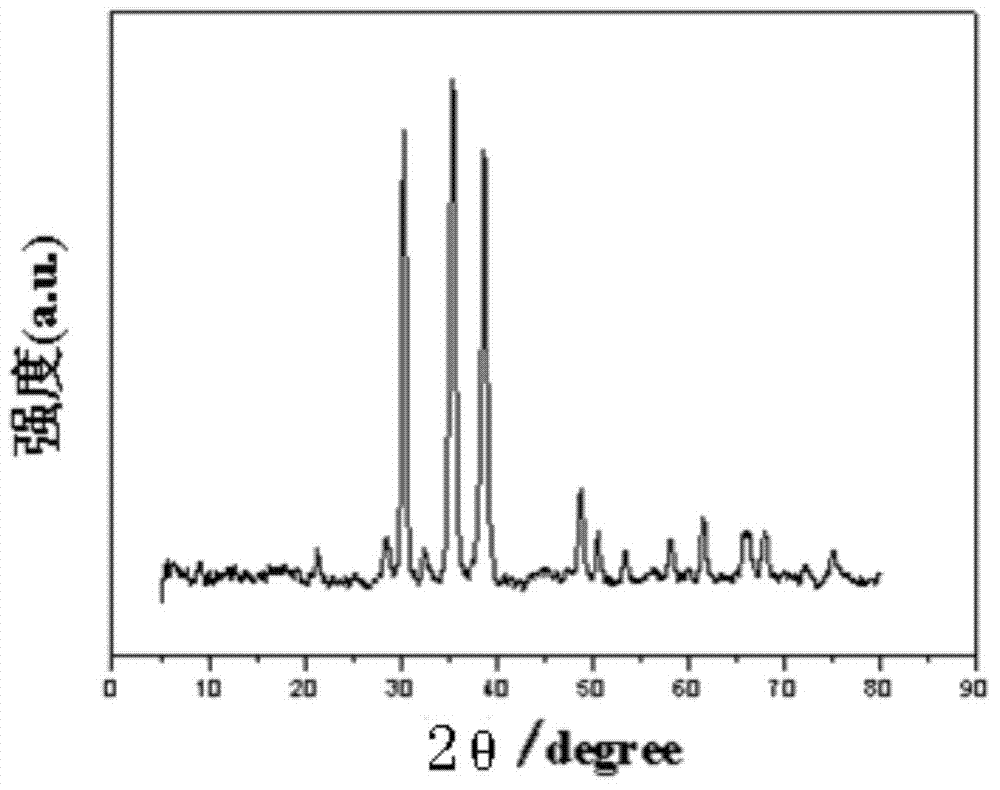

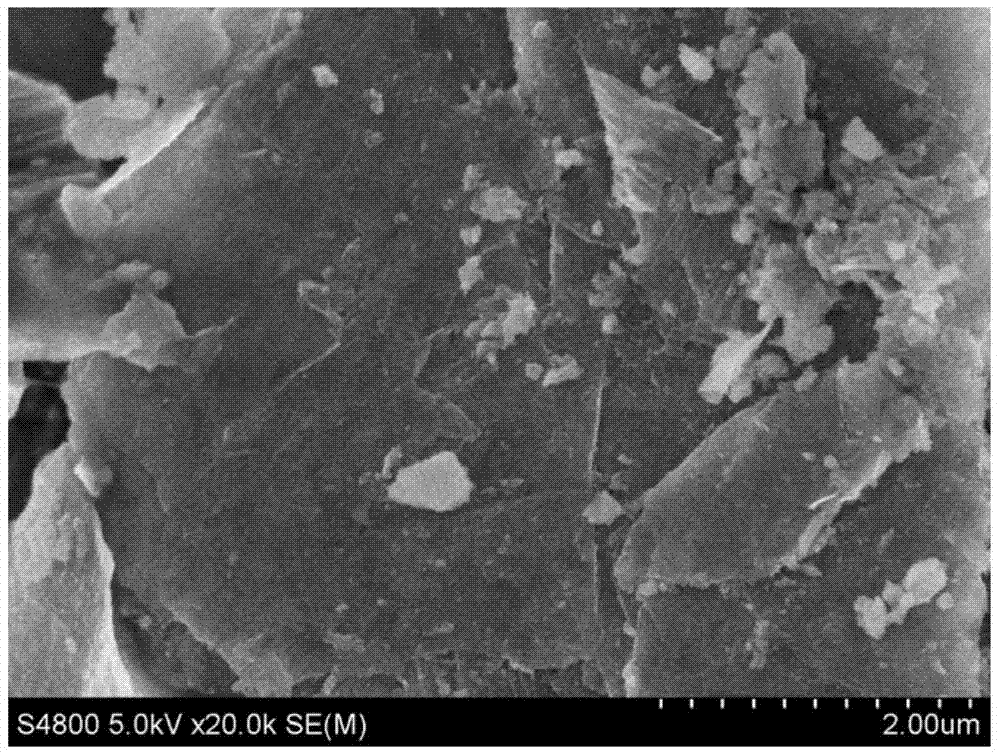

[0017] Specific implementation mode one: a kind of method for detecting NO in this implementation mode x Rare earth-doped modified graphene composite gas sensor, a kind of gas sensor for detecting NO x The rare earth-doped modified graphene composite material gas sensor consists of graphene, distilled water, copper acetate solution with a concentration of 10mmol / L~20mmol / L, cerium nitrate solution with a concentration of 10mmol / L~20mmol / L, and a concentration of Preparation of 16mmol / L~32mmol / L sodium hydroxide solution and 6mmol / L~12mmol / L glucose solution to obtain rare earth doped modified graphene composite material, and rare earth doped modified graphene composite material It is prepared by mixing with a dispersant, adding the dispersion liquid onto the surface of the gold interdigitated electrode, and finally drying;

[0018] The quality of described graphene and the volume ratio of distilled water are 1g:(5~10) L; The quality of described graphene and the volume ratio ...

specific Embodiment approach 2

[0020]Embodiment 2: This embodiment is different from Embodiment 1 in that: the graphene is graphite oxide or expanded graphite. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0021] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the described graphite oxide is prepared according to the following steps:

[0022] 1. Treatment of natural flake graphite: H 2 SO 4 Place in a reaction vessel, heat the reaction vessel to 88°C-92°C under oil bath conditions, then add potassium persulfate, and add potassium persulfate within 16min-20min, then add P 2 o 5 And lower the temperature to 75°C-80°C. Under the condition of stirring at 75°C-80°C, add 200-300-mesh natural flake graphite and react for 30min-40min to obtain a mixture, and place the mixture at a temperature of 75°C-85 Dry in an oven at ℃ for 4h-5h, and finally wash the dried mixture until the pH of the washing liquid is 7 to obtain pretreated graphite; the mass and mass fraction of the natural flake graphite are 18%-22% h 2 SO 4 The volume ratio is 1g:(5~6) mL; the mass ratio of described natural flake graphite and potassium persulfate is 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com