Active pre-crosslinking gel particle

A technology of gel particles and pre-crosslinking, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problem of increasing the viscoelasticity and expansion multiple of bulky particles, poor gel deformation and migration ability, and failure to form Effective plugging and other issues, to improve the water-oil mobility ratio, improve plugging performance, and improve the effect of water flooding front

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] 1. Preparation of active pre-crosslinked gel particles

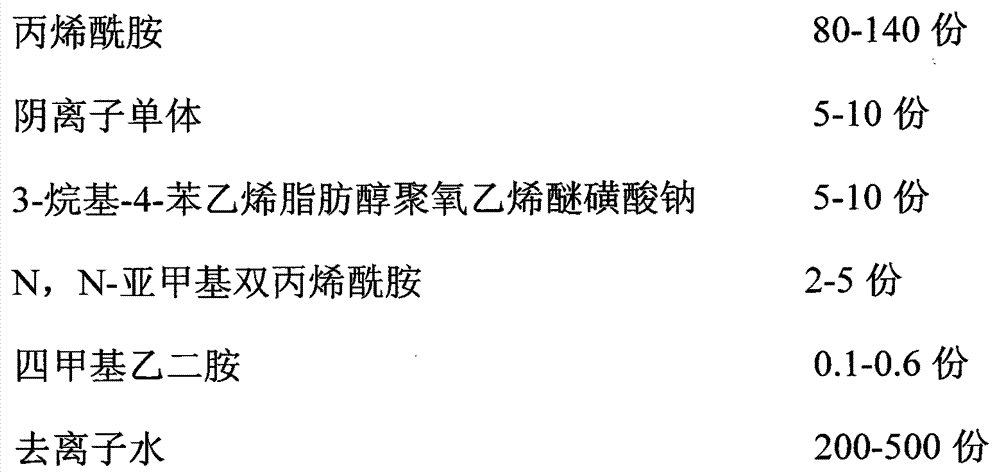

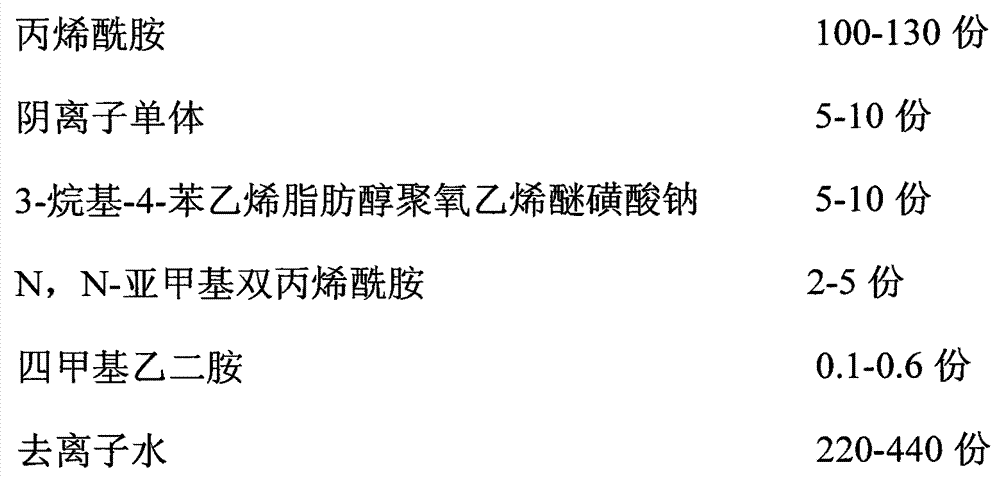

[0026] An active pre-crosslinked gel particle, comprising acrylamide, anionic monomer, sodium 3-alkyl-4-styrene fatty alcohol polyoxyethylene ether sulfonate, N,N-methylenebisacrylamide, tetramethyl Ethylenediamine and deionized water. The active pre-crosslinked gel is mainly obtained by polymerizing and crosslinking composite monomers and crosslinking agent anionic monomers through initiators, and finally through cutting, granulating, drying, pulverizing and other physical means to make the active pre-crosslinking gel. Glue particles.

Embodiment 1

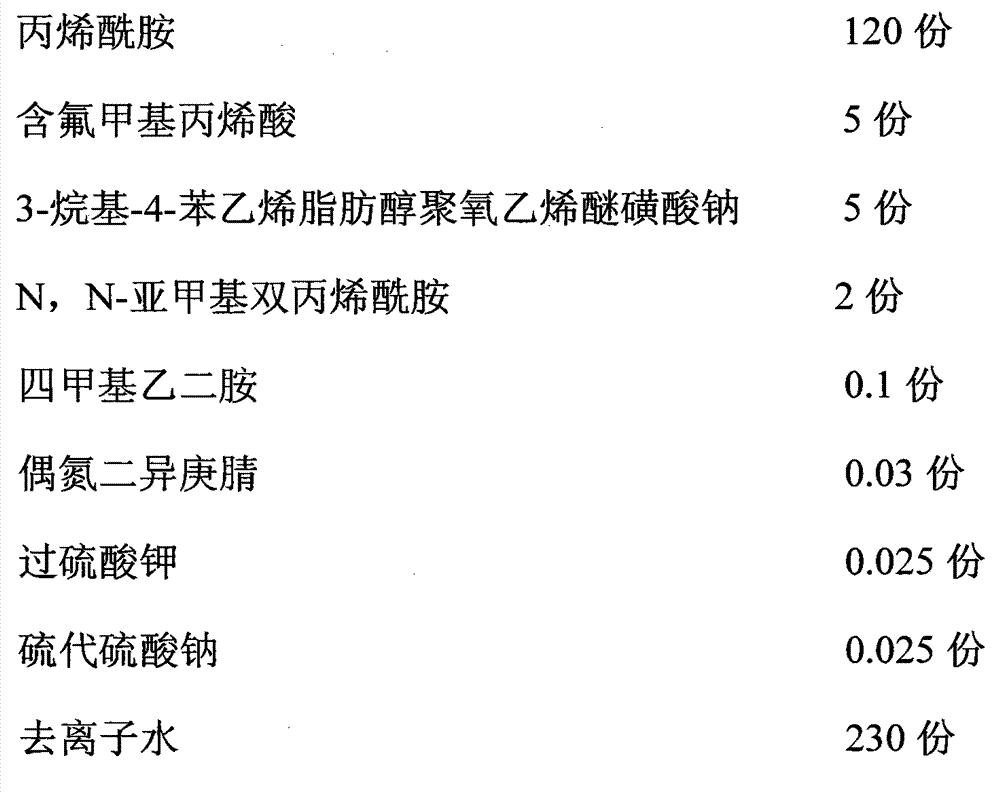

[0028] An active pre-crosslinked gel particle consisting of the following components:

[0029]

[0030] Preparation Process:

[0031] Dissolve 120 parts of acrylamide in 230 parts of deionized water to make an aqueous solution, stir to make it fully dissolved, and add 5 parts of fluorinated methacrylic acid and 5 parts of 3-alkyl-4-benzene to the prepared acrylamide aqueous solution. Sodium ethylene fatty alcohol polyoxyethylene ether sulfonate, 2 parts of N,N-methylenebisacrylamide, and 0.1 part of tetramethylethylenediamine are stirred to form a uniform mixture. Transfer the uniformly mixed mixture into the reactor, and control the temperature of the reactor within the range of 21-22°C. After purging with nitrogen for 30 minutes, add 0.03 part of azobisisoheptonitrile and stir evenly, and continue to purify with nitrogen for 10 minutes. Add 0.025 part of potassium persulfate and stir evenly, then continue to pass nitrogen for 10 minutes, then add 0.025 part of sodium thiosulfate...

Embodiment 2

[0033]

[0034] The preparation process of the active pre-crosslinked gel particles is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com