BiOBr/RGO composite aerogel, preparation method and application of BiOBr/RGO composite aerogel

A composite airgel and graphene airgel technology, applied in the field of photocatalysis, can solve the problems of low efficiency, easy deactivation, difficult separation and recovery, etc., to achieve convenient separation and recovery, high reuse rate, simple and easy preparation method line effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Preparation of BiOBr / RGO Composite Airgel with Efficient Liquid Phase Degradability

[0022] BiBr 3 Add 50 mL of an aqueous solution containing 200 mg of lysine, stir vigorously at room temperature for 30 min to form a uniform white suspension, then add 20 mL of graphene oxide (5 mg / mL), transfer to 100 mL of water In a hot kettle, react at 160°C for 10h. After cooling, the product hydrogel was washed and freeze-dried to obtain the composite airgel, wherein the BiOBr loading was 71.4wt%-90.9wt%.

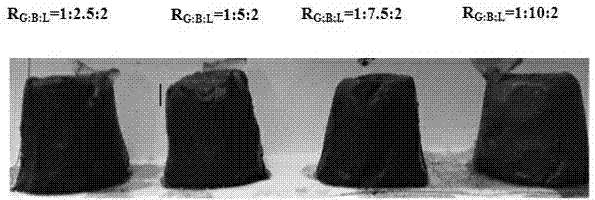

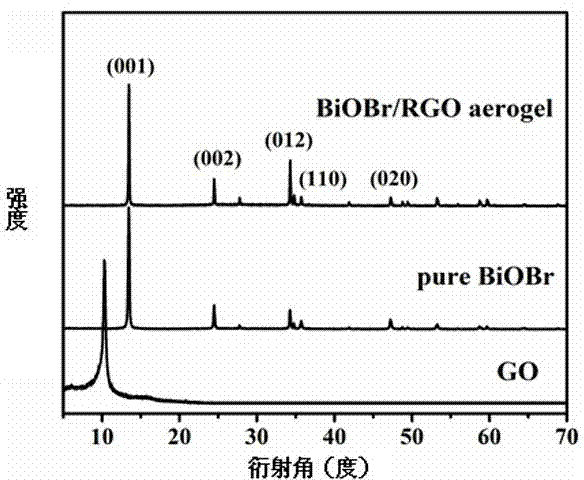

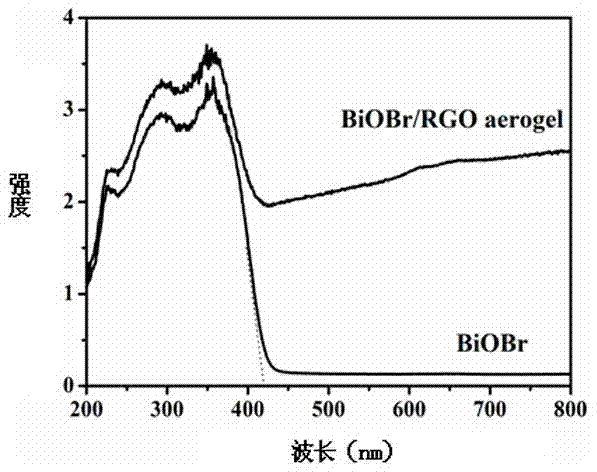

[0023] figure 1 The photos of the BiOBr / RGO composite aerogels with different contents of the present invention are shown, indicating that good aerogels can be formed within this ratio range. figure 2 The X-ray diffraction (XRD) pattern of the BiOBr / RGO composite airgel of the present invention is shown, from which it can be found that the prepared sample is a composite of BiOBr and RGO. image 3 The ultraviolet-visible diffuse reflectance (DRS) diagrams of BiOBr / RGO and ...

Embodiment 2

[0025] Comparison of BiOBr / RGO Composite Airgel and BiOBr Powder Liquid Phase Photocatalytic Degradation of Rhodamine B

[0026] The obtained BiOBr / RGO composite airgel was used to degrade Rhodamine B in liquid phase. The sample was added to 60 mL Rhodamine B solution (20 ppm) for photocatalytic degradation under sunlight. The photocatalytic degradation of Rhodamine B was detected by Cary-500 spectrophotometer. BiOBr / RGO composite airgel of the present invention and BiOBr powder are compared to the degradation of Rhodamine B as follows Figure 5 shown. It can be observed from the figure that in the absence of a catalyst, light hardly degrades Rhodamine B. When adding the composite airgel of the present invention or BiOBr powder, the photocatalytic degradation rate of Rhodamine B is greatly improved. However, when the catalyst of the present invention is illuminated for 3 h, the rhodamine B has been completely decolorized, and the rhodamine B solution is completely degraded a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com