Method for preparing industrial fuel gas through pyrolysis treatment of garbage

A technology of industrial gas and pyrolysis gas, applied in the direction of granular/powdered fuel gasification, gas dedusting, etc., can solve the problems of process equipment that cannot be made into a large scale, complex requirements for waste treatment systems, and low waste treatment efficiency. Achieve the effects of solving excessive water content of garbage and harmless treatment of permeate, improving comprehensive utilization rate and avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

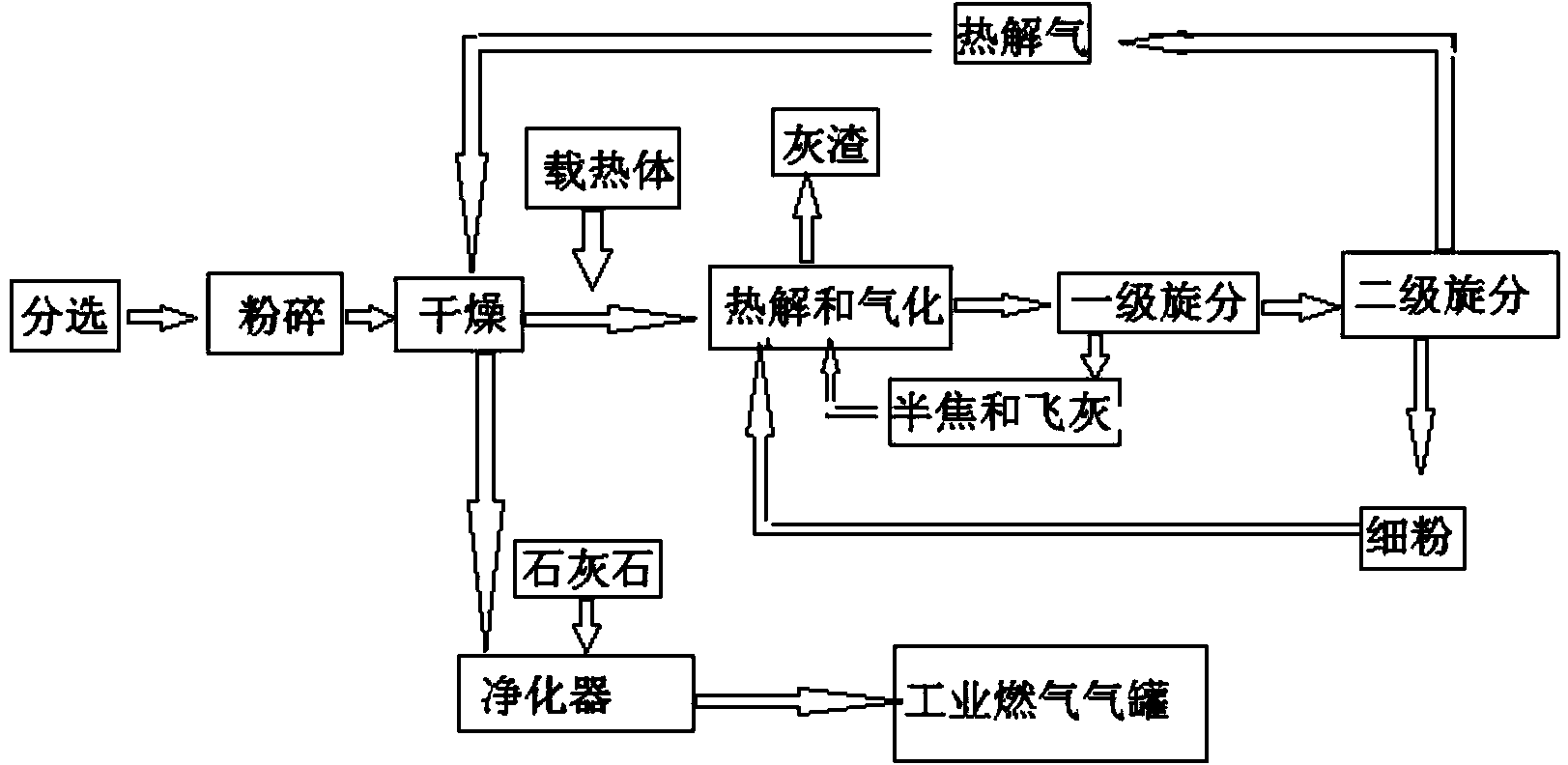

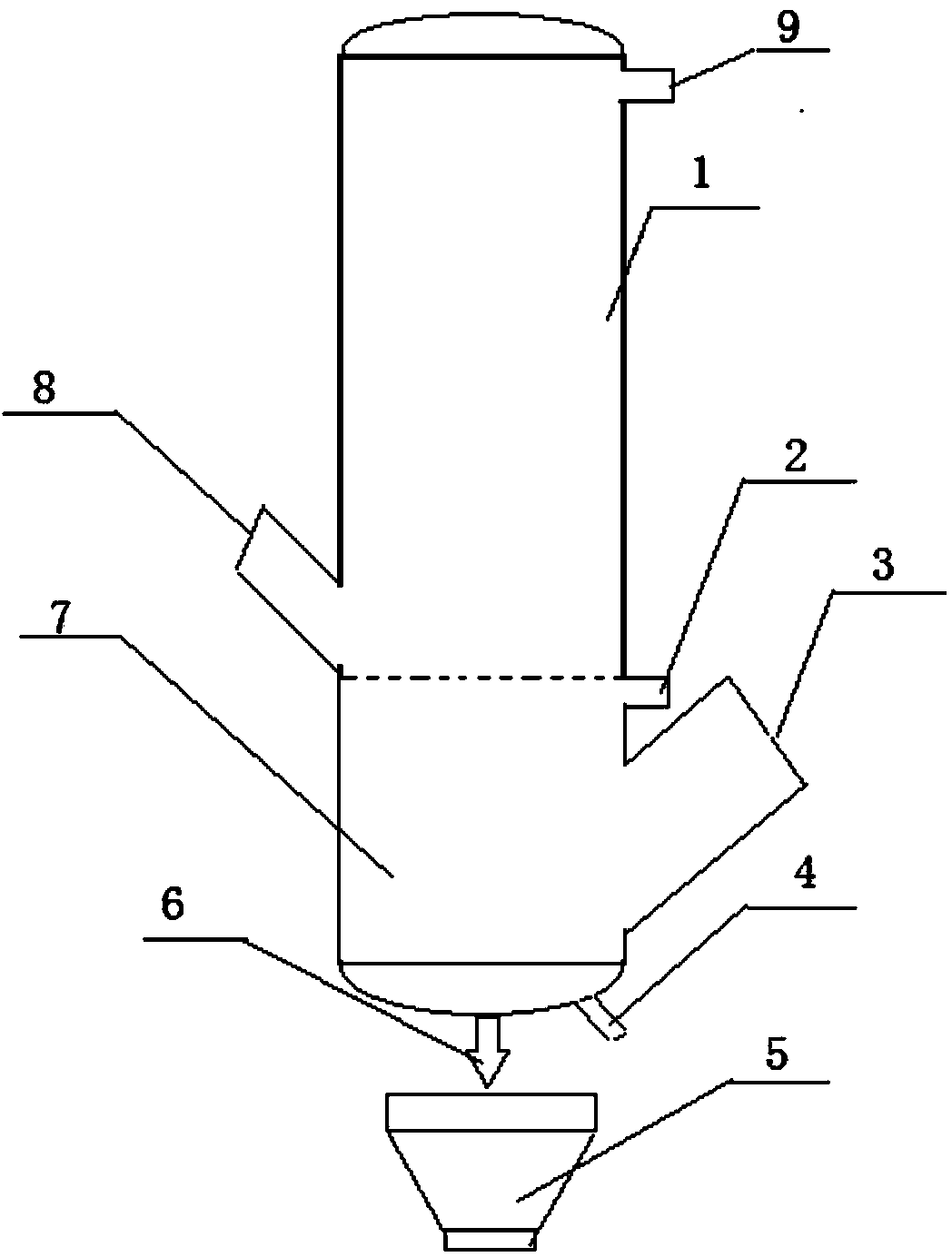

[0023] After the garbage is sorted by the sorting machine, it enters the pulverizer for crushing treatment, and then transfers to the dryer for drying treatment. Pyrolysis and gasification process; the pyrolysis furnace is equipped with a circulating fluidized bed and an entrained flow bed. After the garbage enters, it is quickly mixed with the hot ash and high-temperature gas that circulates and rises. Chlorine, which eliminates tar, phenol, and light oil produced by rapid pyrolysis of garbage after heating; coarse particles fall into the bottom of the furnace, undergo gas-solid mass transfer and heat transfer in the pyrolysis furnace, and undergo a chemical reaction at a temperature of 950°C to form CO, H 2 , CO 2 Mixed gas; and by melting the fly ash at a temperature of 1500°C, the fly ash will fall into the bed material at the bottom of the pyrolysis furnace in the form of liquid, exchange heat with the bed material and cool down to become glassy slag, and pass through th...

Embodiment 2

[0025] After the garbage is sorted by the magnetic separator, it enters the pulverizer for crushing treatment, and then transfers to the tumble dryer for drying treatment, and the pulverized garbage and heat carrier are added to the pyrolysis furnace through the screw feeder To carry out the pyrolysis and gasification process; the pyrolysis furnace is equipped with a circulating fluidized bed and an entrained flow bed. After the garbage enters, it is quickly mixed with the hot ash and high-temperature gas that circulates and rises. The fine particles flow upward and are pyrolyzed at a temperature of 700°C. and dechlorination, eliminating tar, phenol, and light oil generated by rapid pyrolysis of garbage after heating; coarse particles fall into the bottom of the furnace, and undergo gas-solid mass transfer and heat transfer in the pyrolysis furnace and chemical reactions occur at a temperature of 900 °C , producing CO, H 2 , CO 2 Mixed gas; and by melting the fly ash at a tem...

Embodiment 3

[0027]After the garbage is sorted by the sorting machine, it enters the pulverizer for crushing treatment, and then transfers to the dryer for drying treatment. During the pyrolysis and gasification process, the pyrolysis furnace is equipped with a circulating fluidized bed and an entrained flow bed. After the garbage enters, it is quickly mixed with the hot ash and high-temperature gas that circulates and rises, and the fine particles flow upward. Chlorine, which eliminates tar, phenol, and light oil produced by rapid pyrolysis of garbage after heating; coarse particles fall into the bottom of the furnace, undergo gas-solid mass transfer and heat transfer in the pyrolysis furnace, and undergo a chemical reaction at a temperature of 1000 ° C to form CO, H 2 , CO 2 Mixed gas; and by melting the fly ash at a temperature of 1800°C, the fly ash will fall into the bed material at the bottom of the pyrolysis furnace in the form of liquid, and exchange heat with the bed material to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com