Preparation method for nitrogen-doped graphene

A nitrogen-doped graphene and montmorillonite technology is applied in the preparation of nitrogen-doped graphene for supercapacitors and the field of graphene preparation. problems, to achieve the effect of increasing electrochemical active sites, increasing effective specific surface area, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

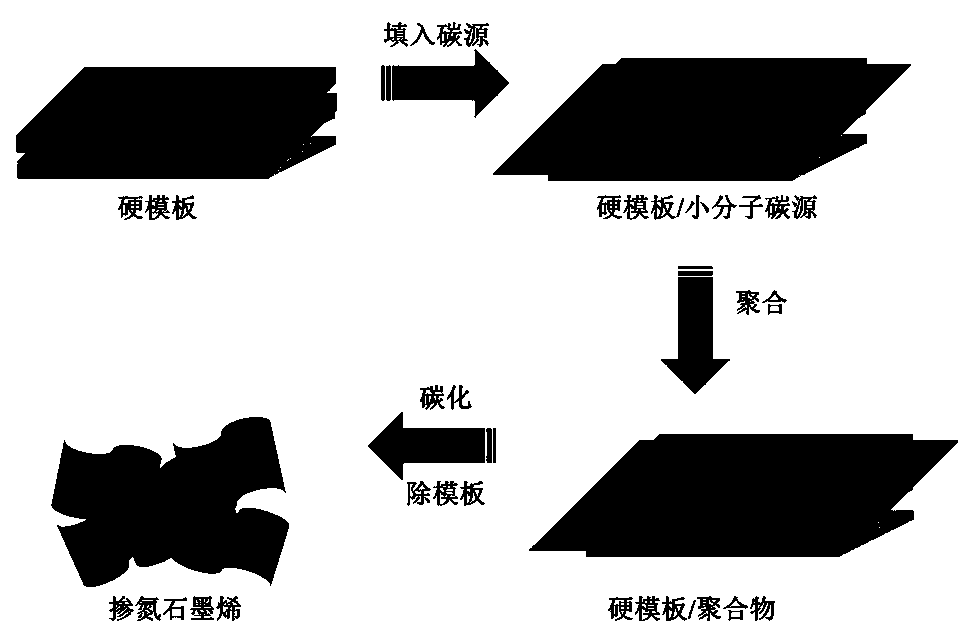

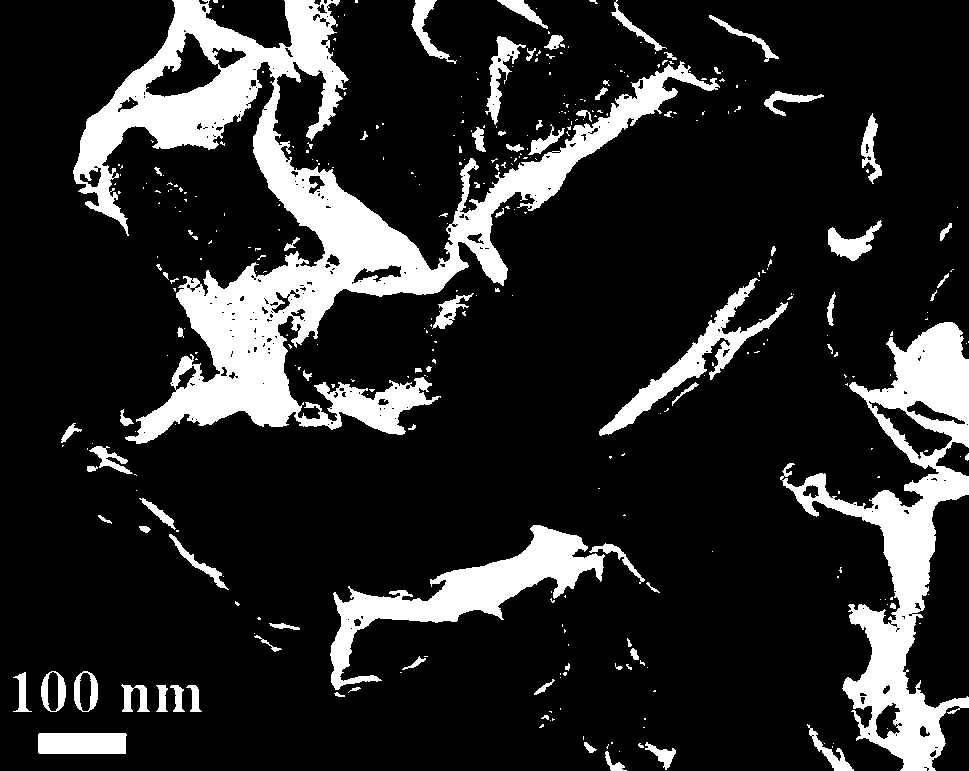

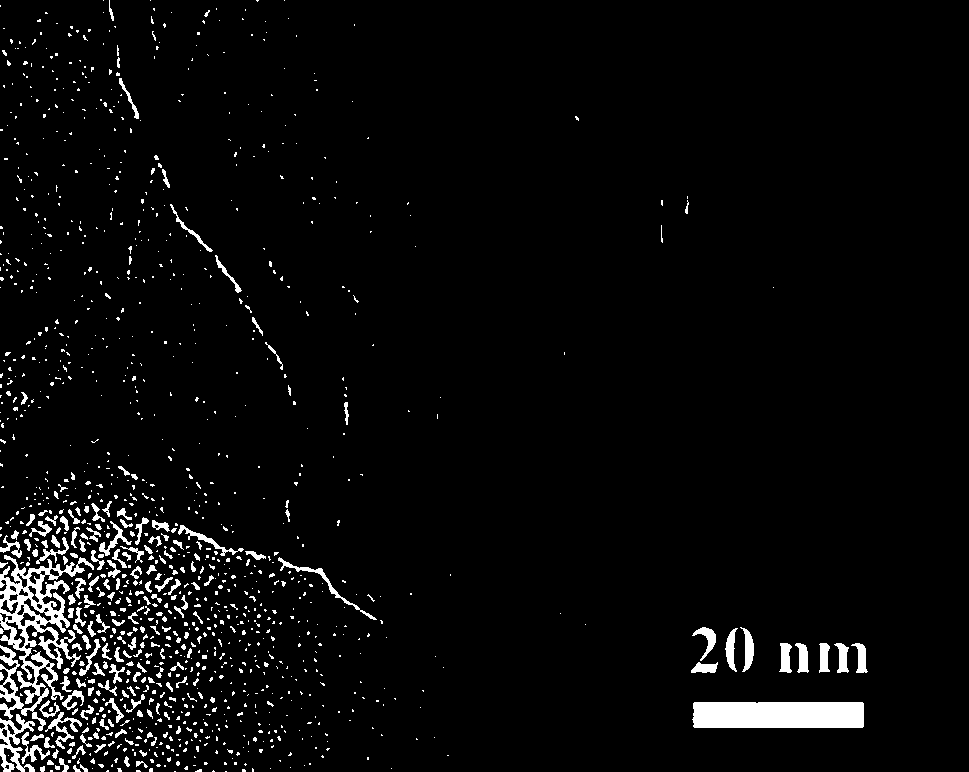

[0028] Such as figure 1 As shown, first, 200 mg of hard template montmorillonite with a parallel plate structure and a layer spacing of 1 nm is uniformly dispersed in water to form a suspension with a mass fraction of 0.5 mg / mL, and a certain amount of hydrochloric acid is added to it to adjust its The pH value is 1-5. Then, 100 mg of dopamine was added as a carbon source so that the mass ratio to montmorillonite m 碳源 / m 蒙脱石 =1:2. After stirring evenly, 25 ml of a tris solution with a concentration of 10 mmol / mL was added to induce the polymerization of dopamine, and the polymerization time was 24 hours. The resulting polymer precipitate was filtered, washed and dried, calcined and carbonized in a tube furnace, and heated to 900°C at a rate of 3°C / min under a nitrogen atmosphere, and kept for 2 h. The calcined product was washed with a 30% hydrofluoric acid solution to remove the hard template, washed repeatedly with deionized water, filtered with suction, and dried to obt...

Embodiment 2

[0033] First, 200 mg of hard template montmorillonite with a parallel plate structure and a layer spacing of 3 nm is evenly dispersed in water to form a suspension with a mass fraction of 1 mg / mL, and a certain amount of hydrochloric acid is added to it to adjust its pH to 1 -5. Then, add 100 mg of pyrrole as a carbon source so that the mass ratio of montmorillonite to m 碳源 / m 蒙脱石 =1:2. After stirring evenly, 25 ml of a tris solution with a concentration of 10 mmol / mL was added to induce polymerization of pyrrole, and the polymerization time was 24 hours. The resulting polymerized precipitate was suction filtered, washed and dried, calcined and carbonized in a tube furnace, and raised to 900°C at a rate of 3°C / min under a nitrogen atmosphere, and kept for 2h. The calcined product was washed with a 30% hydrofluoric acid solution to remove the hard template, washed repeatedly with deionized water, filtered with suction, and dried to obtain high-quality nitrogen-doped graphene...

Embodiment 3

[0035] First, 100 mg of hard template montmorillonite with a parallel plate structure and a layer spacing of 2 nm is evenly dispersed in water to form a suspension with a mass fraction of 1 mg / mL, and a certain amount of hydrochloric acid is added to it to adjust its pH to 1 -5. Then, 100 mg of dopamine was added as a carbon source so that its mass ratio to montmorillonite m 碳源 / m 蒙脱石 =1:1. After stirring evenly, 25 ml of a tris solution with a concentration of 10 mmol / mL was added to induce the polymerization of dopamine, and the polymerization time was 24 hours. The resulting polymer precipitate was suction filtered, washed and dried, calcined and carbonized in a tube furnace, and kept at 900°C for 2 h at a rate of 3°C / min under a nitrogen atmosphere. The calcined product was washed with a 30% hydrofluoric acid solution to remove the hard template, washed repeatedly with deionized water, filtered with suction, and dried to obtain high-quality nitrogen-doped graphene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com