Flower-like nanocomposite material, preparation method thereof, electrode material and preparation method thereof

A technology of nanocomposite materials and electrode materials, which is applied in the fields of flower-like nanocomposite materials and their preparation, electrode materials and their preparation, and can solve the problems of unstable metal oxides and unstable cycle performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The present invention also provides a preparation method of the flower-shaped nanocomposite material described in the above technical solution, comprising the following steps:

[0037] (1) Dispersing and mixing nickel nitrate, graphite oxide and graphite-like phase carbon nitride in water, adjusting the pH value of the mixture to 9-11 to obtain a dispersion;

[0038] (2) Under airtight conditions, heat-treat the dispersion liquid obtained in the step (1) to obtain a flower-like nanocomposite material.

[0039] The invention mixes nickel nitrate, graphite oxide and graphite-like phase carbon nitride in water to obtain a mixed solution.

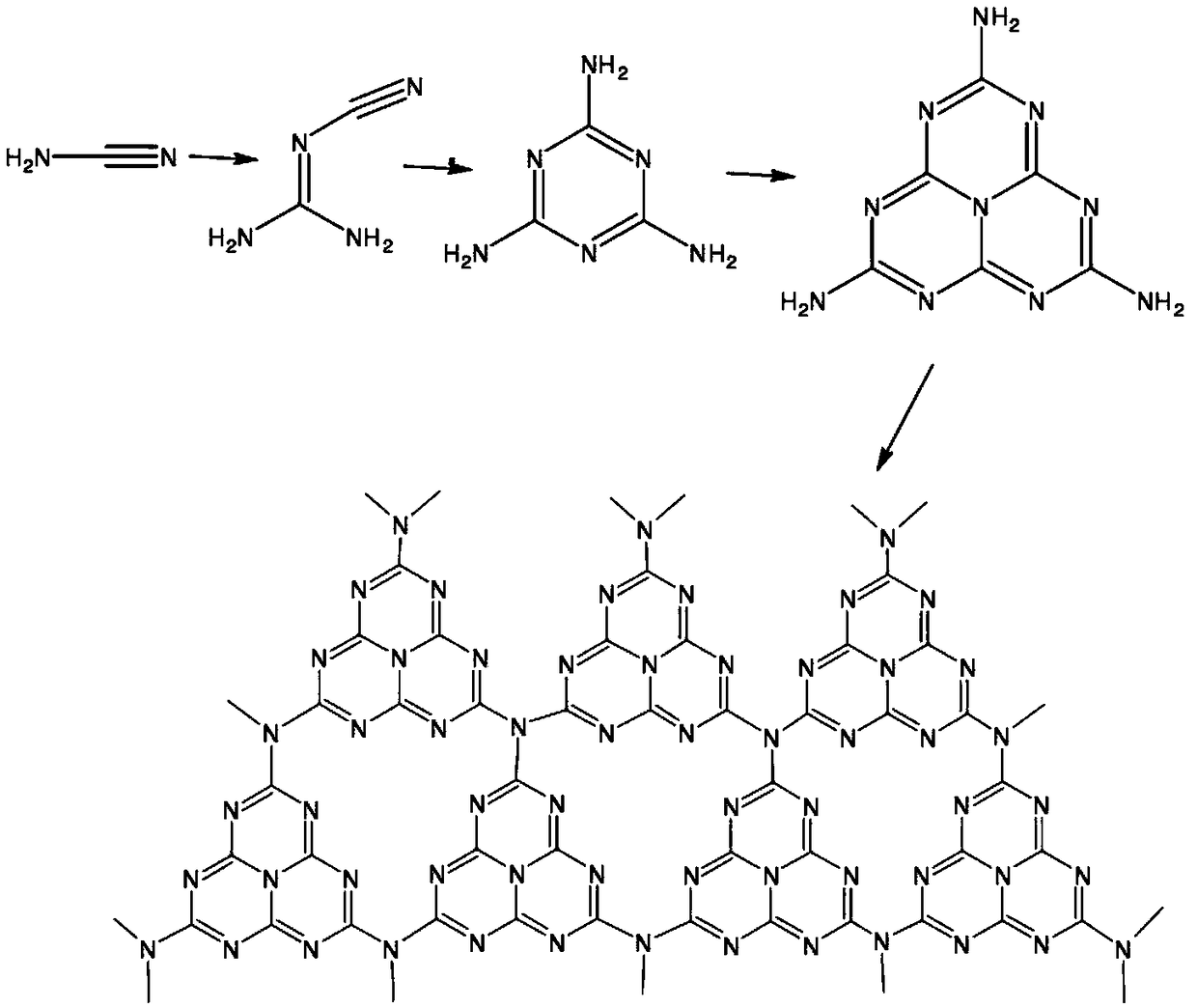

[0040]In the present invention, the preparation method of the graphite-like carbon nitride preferably comprises the following steps:

[0041] (a) Calcining the urea, grinding the calcined product and dispersing it in water to obtain a suspension;

[0042] (b) Under airtight conditions, heat-treat the suspension obtained in the step (a)...

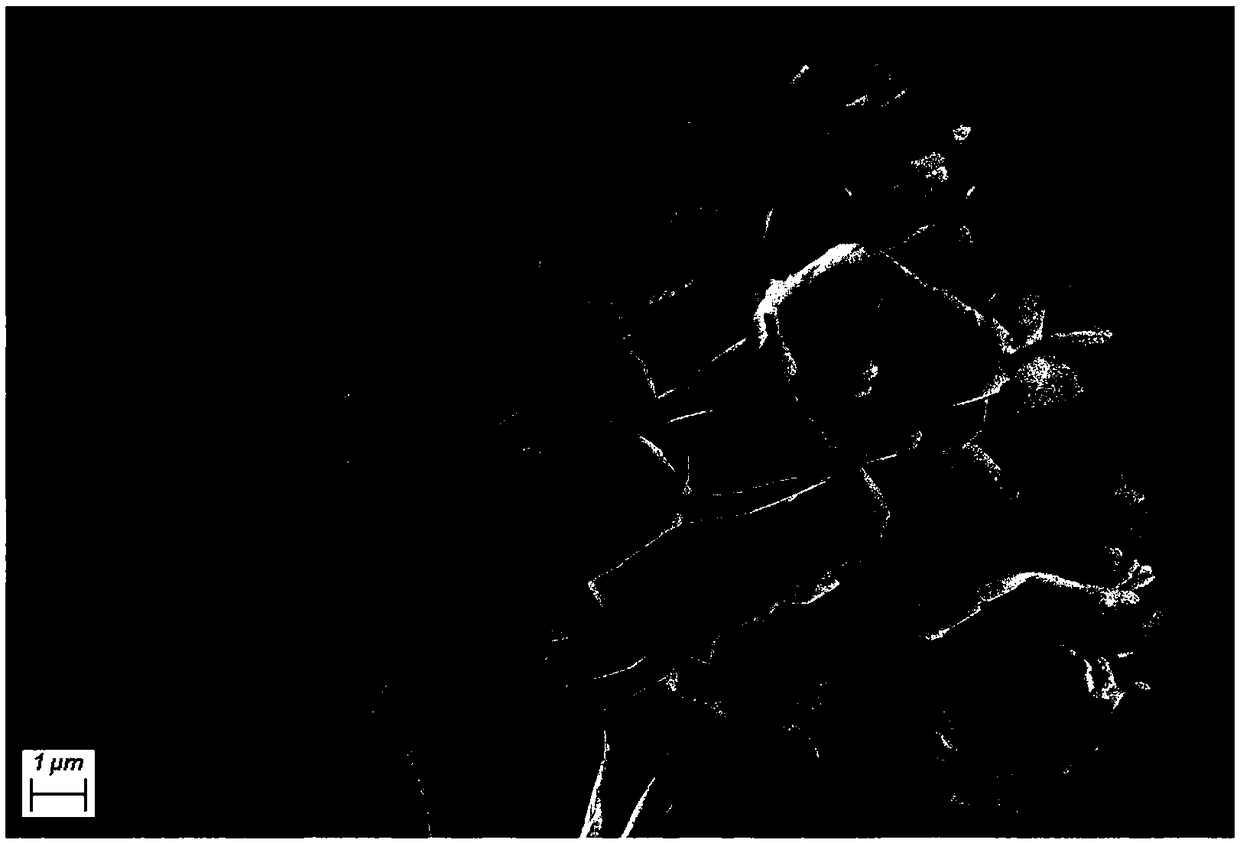

Embodiment 1

[0073] Graphite oxide (GO) was prepared by modified Hummers method using 325 mesh graphite powder as raw material. The urea was ground, moved into a crucible, wrapped the crucible with tinfoil, and calcined in a muffle furnace at a high temperature of 500°C for 3 hours, and the product was ground in deionized water and ultrasonically dispersed to form a suspension to obtain a 2.5 mg / mL solution. Move it into a polytetrafluoroethylene reactor, react at 180°C for 10 hours, and obtain graphite-like carbon nitride (g-C 3 N 4 ). Weigh 50 mg of graphite oxide (GO) and 50 mg of graphite-like carbon nitride (g-C 3 N 4 ), ultrasonic treatment in 100ml deionized water, ultrasonic time is 30min, ultrasonic power is 540W, obtain 1mg / mL suspension, press Ni(OH) 2 , g-C 3 N 4 Calculate and weigh an appropriate amount of nickel nitrate to prepare nickel nitrate aqueous solution with a mass ratio of 16:1:1 to RGO, and move the nickel nitrate aqueous solution into graphite oxide (GO) and...

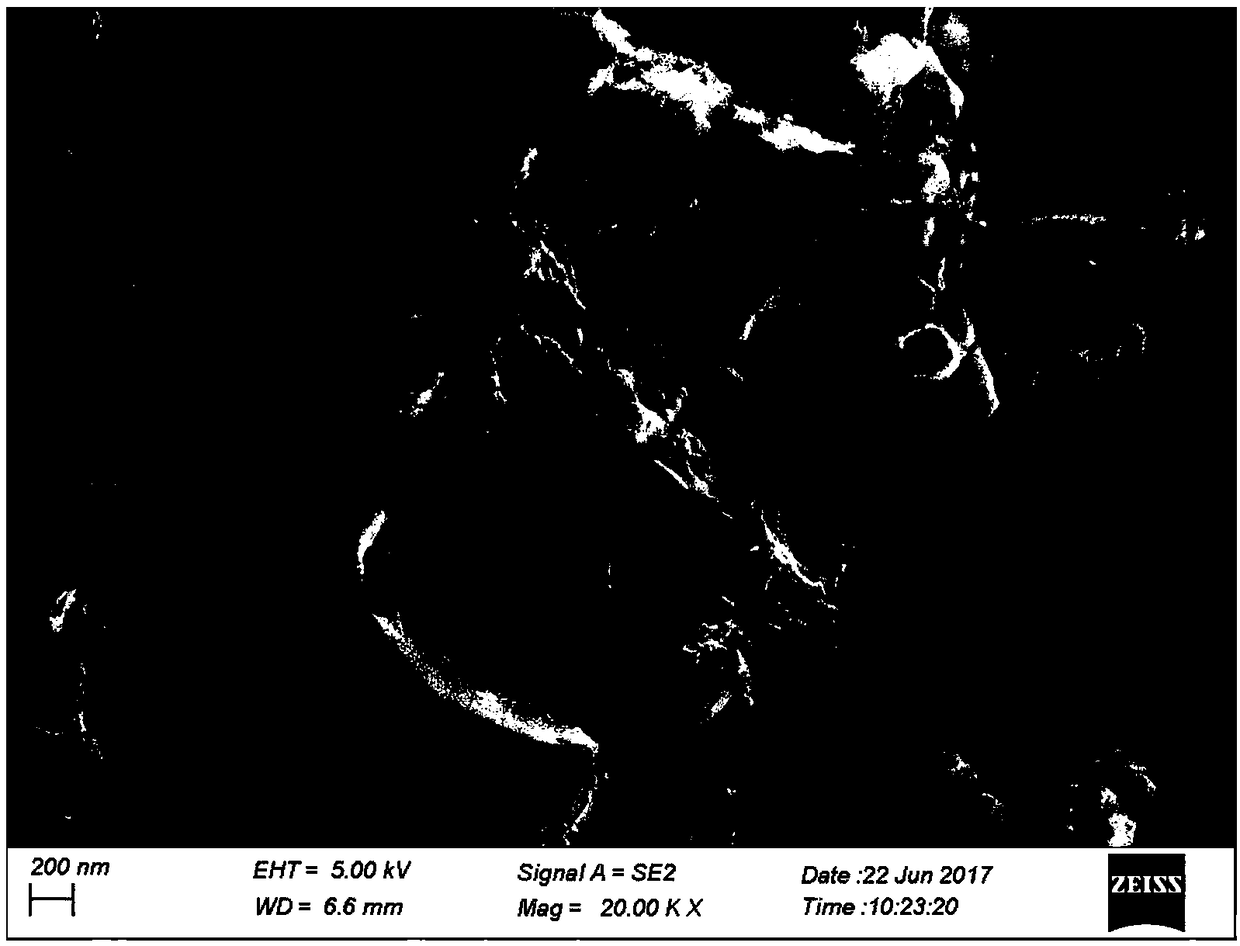

Embodiment 2

[0075] Graphite oxide (GO) was prepared by modified Hummers method using 325 mesh graphite powder as raw material. The urea was ground, moved into a crucible, wrapped the crucible with tinfoil, and calcined in a muffle furnace at a high temperature of 500°C for 3 hours, and the product was ground in deionized water and ultrasonically dispersed to form a suspension to obtain a 2.5 mg / mL solution. Move it into a polytetrafluoroethylene reactor, react at 185°C for 10 hours, and obtain graphite-like carbon nitride (g-C 3 N 4 ). Weigh 50 mg of graphite oxide (GO) and 50 mg of graphite-like carbon nitride (g-C 3 N 4 ), ultrasonic treatment in 100ml deionized water, ultrasonic time is 30min, ultrasonic power is 540W, obtain 1mg / mL suspension, press Ni(OH) 2 , g-C 3 N 4, RGO mass ratio is 16:1:1 Calculate and weigh an appropriate amount of nickel nitrate to configure nickel nitrate aqueous solution, move the nickel nitrate aqueous solution into graphite oxide (GO) and graphite-l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com